Do you have a question about the Omron Viper 650 and is the answer not in the manual?

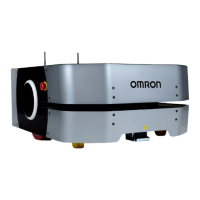

Details about the Viper 650/850 robot and its core components like eMB-40/60R.

Information on accessing support resources, including the corporate website and related manuals.

Explanation of alert levels, icons, and specific hazards like falling hazards.

Procedures for handling emergencies, including releasing brakes and E-Stops.

Guidance on user responsibilities, general hazards, and personnel qualifications for safe operation.

Description of robot behavior related to hardstops, limiting devices, and singularities.

Defines the proper applications and prohibited uses for the Viper robots.

Information on robot modifications, manufacturer declarations, and safety guides.

Guidelines for the proper disposal of the robot and its components.

Instructions for carefully inspecting the robot and its packaging upon arrival.

Guidelines for safely repacking the robot for transport or relocation.

Specifies the necessary environmental conditions for robot installation and operation.

Detailed precautions and procedures for safely transporting the robot.

Instructions and diagrams for physically mounting the robot to its base.

Critical information on properly grounding the robot system for safety.

Guidance on installing the front panel, ensuring it's outside the robot's workspace.

Details and identification of connectors on the robot's interface panel.

Information on connecting air lines and signal wiring for robot operation.

Guidelines for designing end-effectors considering mass, center of gravity, and inertia.

Overview of the eMotionBlox-40/60R as a distributed servo controller and amplifier.

Identification and description of all connectors on the eMB-40/60R interface panel.

Details on the status LED, status panel, and brake release functionality.

Information on various methods for connecting digital I/O to the robot system.

Detailed explanation of XIO signals, including input and output specifications.

Instructions and diagrams for mounting the eMB-40/60R unit, including dimensions and clearances.

Details on connecting system cables when not using a SmartController EX.

Instructions for connecting system cables when the SmartController EX is included.

Information on various optional cables like XIO Breakout and DB9 Splitter cables.

Instructions for installing and running the ACE software for system configuration.

Procedure for connecting the Arm Power/Signal cable between the robot and controller.

Specifications and procedures for connecting the 24 VDC power supply.

Specifications and procedures for connecting the 200-240 VAC power supply.

Essential guidelines for proper grounding of the robot system for safe operation.

Instructions for integrating user-supplied safety devices like E-stops and gates.

Explanation of alpha-numeric codes displayed on the eMB-40/60R status panel.

Procedures for releasing robot brakes using manual release boxes or switches.

Description of the front panel components, including mode switches and E-Stop buttons.

Step-by-step guide for initial system power-up, verification, and setup.

Guidance on robot programming using ACE software and eV+.

Instructions for applying directional labels to robot joints for axis identification.

Information regarding a specific caution label related to Joint 4 rotation.

Identification of parts that can be replaced by the user or qualified personnel.

Summary of preventive maintenance procedures and recommended frequencies.

Procedures for regularly testing safety systems like E-stops and interlocks.

Instructions for checking and tightening robot base mounting bolts.

Detailed procedure for replacing the robot's encoder backup batteries.

Step-by-step guide for removing and installing the eMB-40/60R amplifier.

Procedures for synchronizing the robot with the eMB-40/60R controller.

Instructions for replacing the high-power indicator lamp on the front panel.

Detailed dimensional drawings and work envelope information for Viper 650 and 850.

Specific dimensions related to the robot's tool flange mounting.

Comprehensive technical data including physical, performance, and stopping characteristics.

Overview of the IP54/65 option providing dust and splash protection for the robot.

Highlights differences in installation environment and connector panels for the IP54/65 model.

Introduction to the Class 10 Cleanroom models of the Viper robots.

Details on differences for the Cleanroom robot, including specifications and connector panels.

Information on air lines and signal wiring specific to the Cleanroom robot model.

Description of the Cleanroom Cover at the J6 flange, not present on standard robots.

Specifies the cable clearance dimension at the back of the Cleanroom robot.

Procedure for replacing encoder backup batteries on the Cleanroom robot.

Overview of the status panel display and codes for troubleshooting robot status.

| Payload | 5 kg |

|---|---|

| Reach | 650 mm |

| Repeatability | ±0.02 mm |

| Axes | 6 |

| Weight | 27 kg |

| Mounting | Floor, Wall |