Cylinder Block, Liners, Pistons, and Rods

02

030

8

RG,RG34710,107 –19–01NOV00–2/4

RG8302 –UN–06DEC97

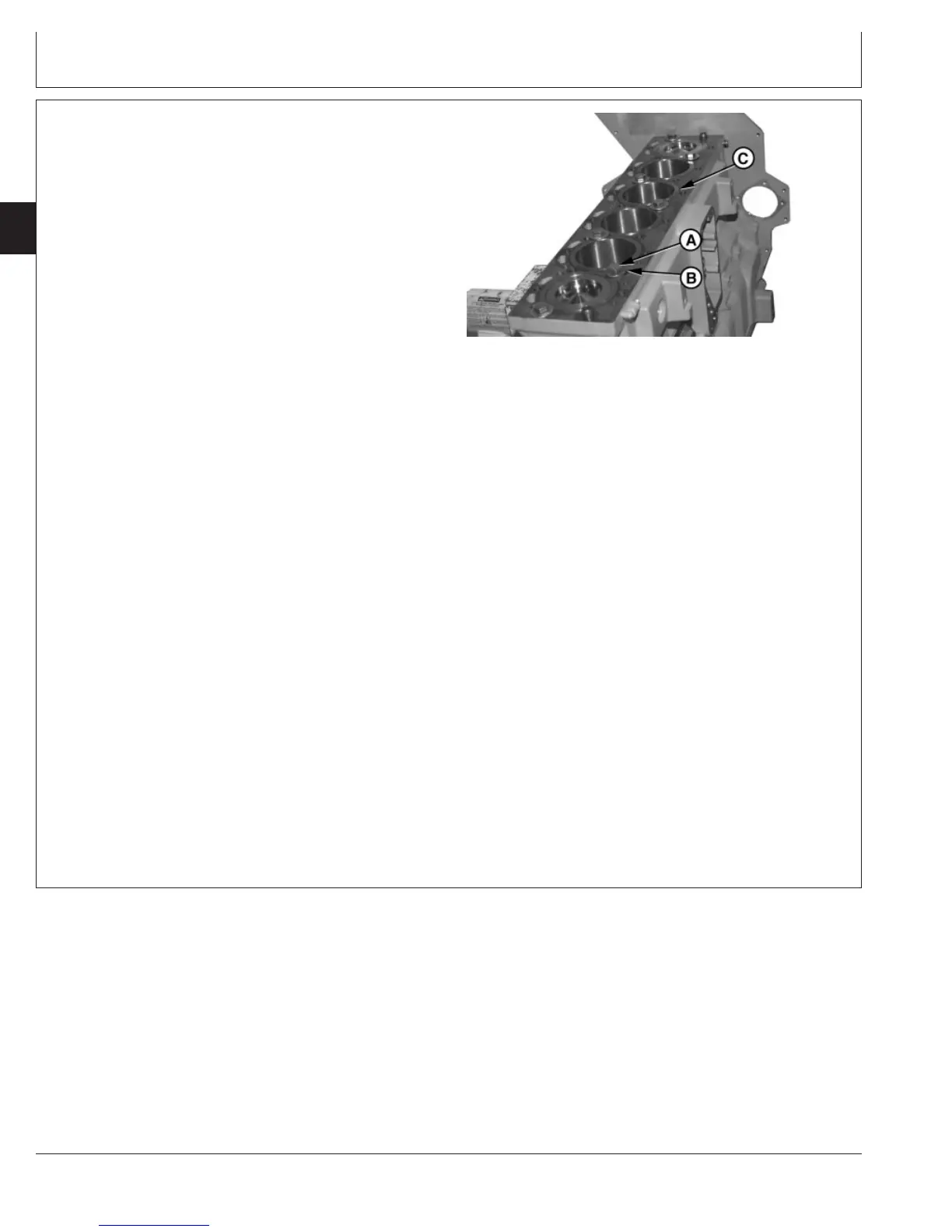

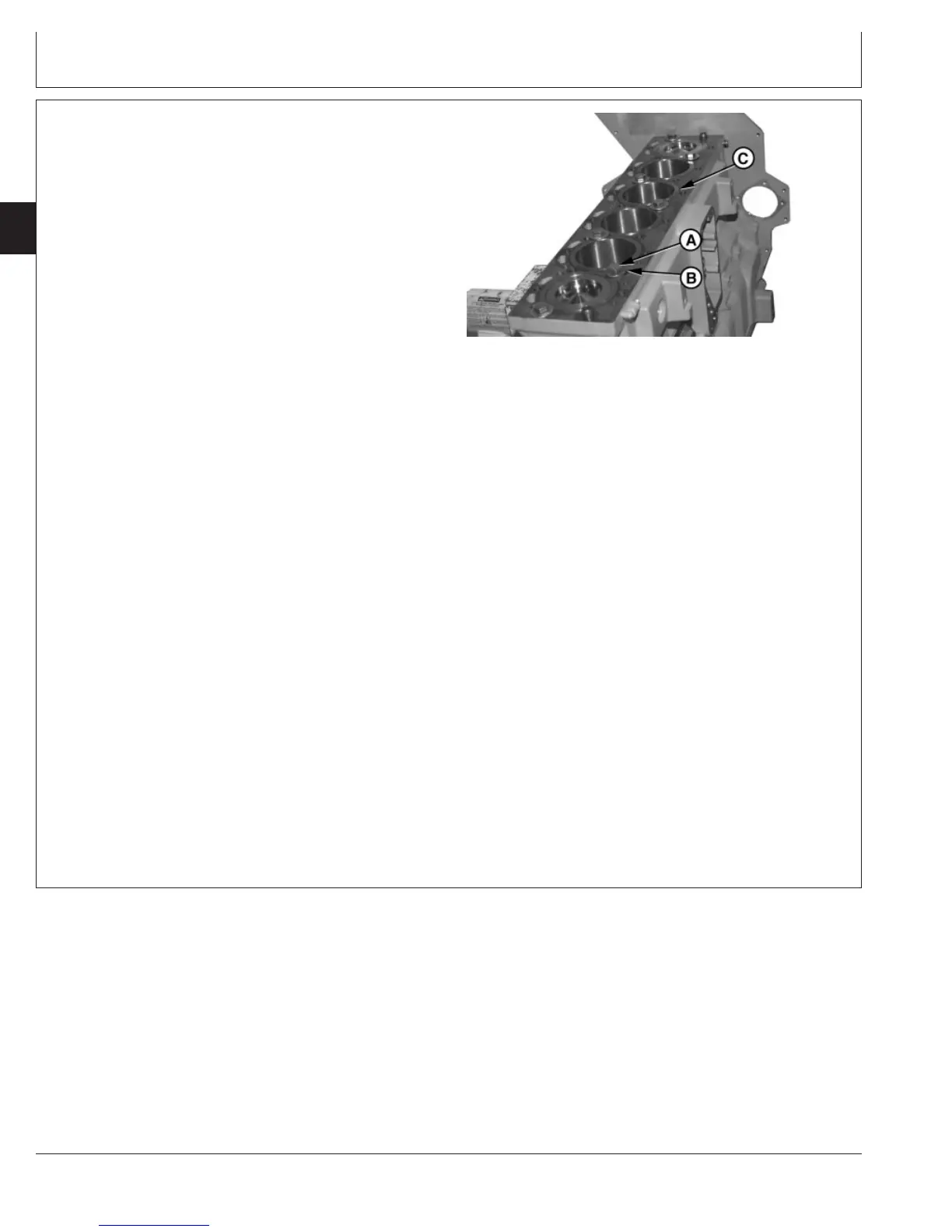

Bolting Liners Down

A—Long Cap Screws

B—Thick Washers

C—Bolt Down Cylinder Liners

IMPORTANT: Do not rotate crankshaft with cylinder

head removed unless liners are bolted

down. Bolt liners down before removing

piston.

Cap screws and washers must be

tightened to 68 N•m (50 lb-ft) to achieve

an accurate reading when checking

liner standout (height above block), as

detailed later in this group.

5. Use seven M16 x 2.0 x 55 mm (2.17 in.) long cap

screws (A) and 5/8 in. ID x 1-3/4 in. OD x 3.18 mm

(1/8 in.) thick washers (B) to bolt down cylinder liners

(C) in the seven locations as shown. Tighten cap

screws to specifications.

Specification

Cylinder Liner Cap Screws (For

Checking Liner Standout)—

Torque 68 N•m (50 lb-ft).............................................................................

6. Before removing pistons, visually inspect condition of

cylinder liners with pistons at bottom dead center

“BDC”. Liners will require replacement if:

• The crosshatch honing pattern is not visible

immediately below the top ring turn-around area.

• Liners are pitted or contain deep vertical scratches

that can be detected by the fingernail.

No further inspection is required if any one of the

above conditions is found.

Continued on next page

CTM100 (06APR04)

02-030-8

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=148

Loading...

Loading...