Group 100

Starting and Charging Systems

02

100

1

DPSG,OUO1004,1005 –19–23SEP02–1/1

Remove and Install Alternator (OEM Engines)

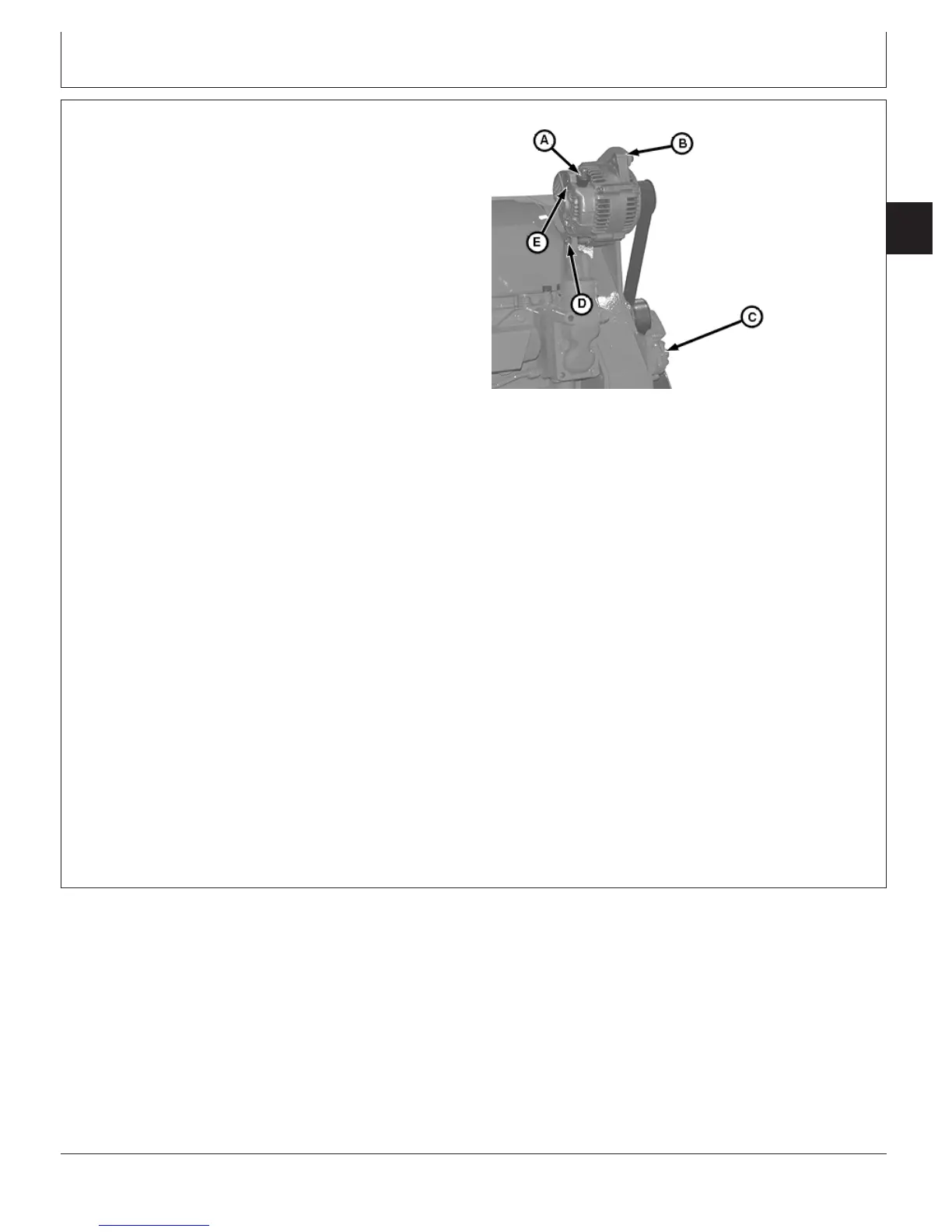

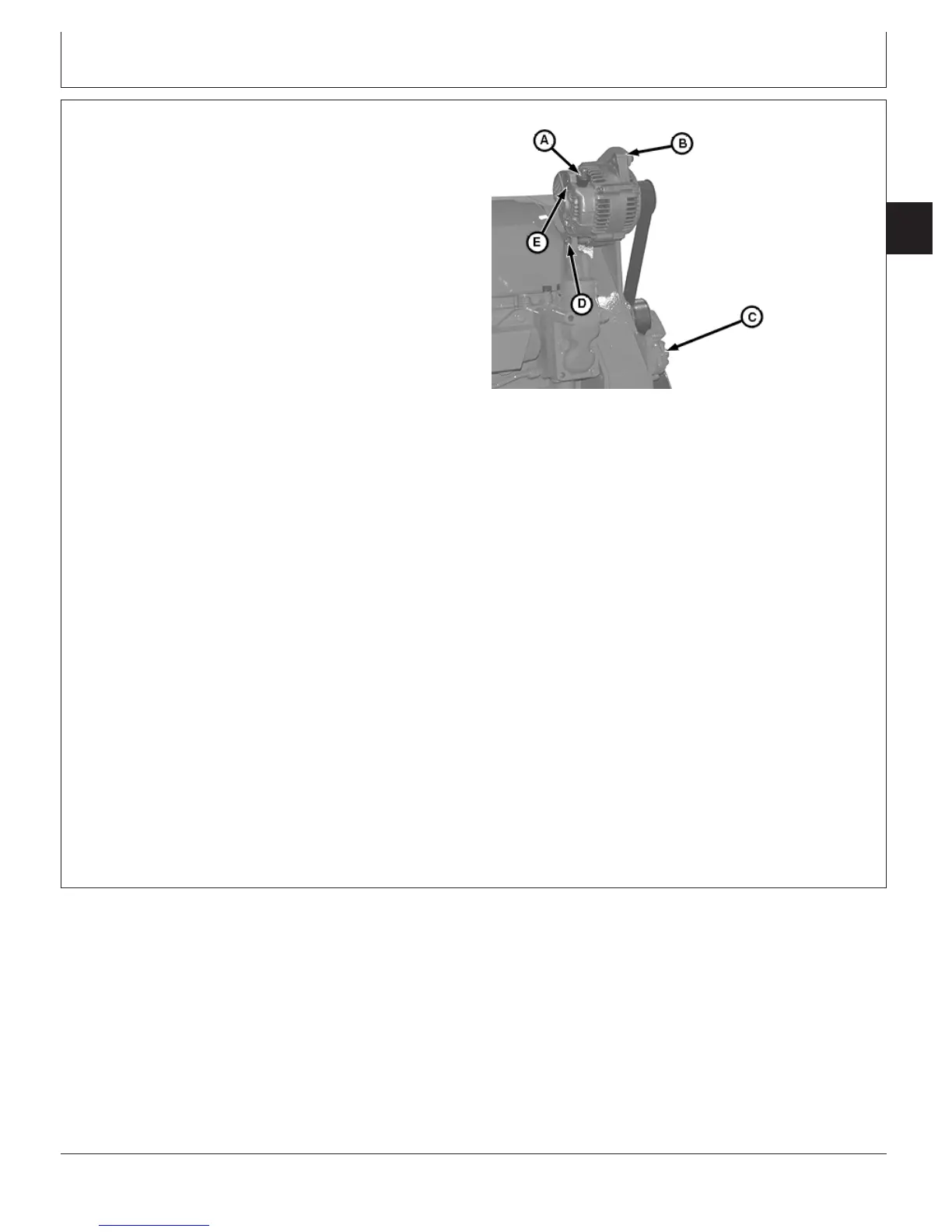

RG10286 –UN–20AUG99

Alternator

A—Positive Wire Terminal

B—Alternator Strap

C—Belt Tensioner

D—Mounting Cap Screw and Nut

E—Regulator Connector Terminal

IMPORTANT: The alternator is designed with a

Transient Voltage Protector (TVP) to

protect the engine electronics. A regular

alternator without the TVP could cause

extensive damage to the electronics.

NOTE: For test and repair of alternator, refer to CTM 77.

1. Disconnect battery ground (-) cable.

2. Disconnect positive (+) red wire (A) and regulator

connector (E) (shown disconnected).

3. Remove alternator belt using a 1/2 in. drive ratchet on

the belt tensioner (C).

4. Remove mounting cap screws from adjusting strap (B).

Remove cap screw and nut (D) and remove alternator.

5. Install alternator in reverse order.

6. Torque alternator mounting hardware to the following

specifications.

Alternator Strap Mounting Hardware—Specification

M8 Cap Screw—Torque 25 N•m (18 lb-ft)..................................................

M10 Cap Screw—Torque 50 N•m (37 lb-ft)................................................

1/2 in. Cap Screw—Torque 61 N•m (45 lb-ft).............................................

Alternator Foot Mounting Hardware—Specification

M10 Cap Screw—Torque 70 N•m (52 lb-ft)................................................

M12 Cap Screw—Torque 60 N•m (44 lb-ft)................................................

7. Inspect alternator belt for cracks and wear.

CTM100 (06APR04)

02-100-1

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=329

Loading...

Loading...