Cylinder Block, Liners, Pistons, and Rods

02

030

25

RG,RG34710,118 –19–13AUG99–1/1

Inspect Piston Pin and Pin Bore in Piston

RG5231 –UN–05DEC97

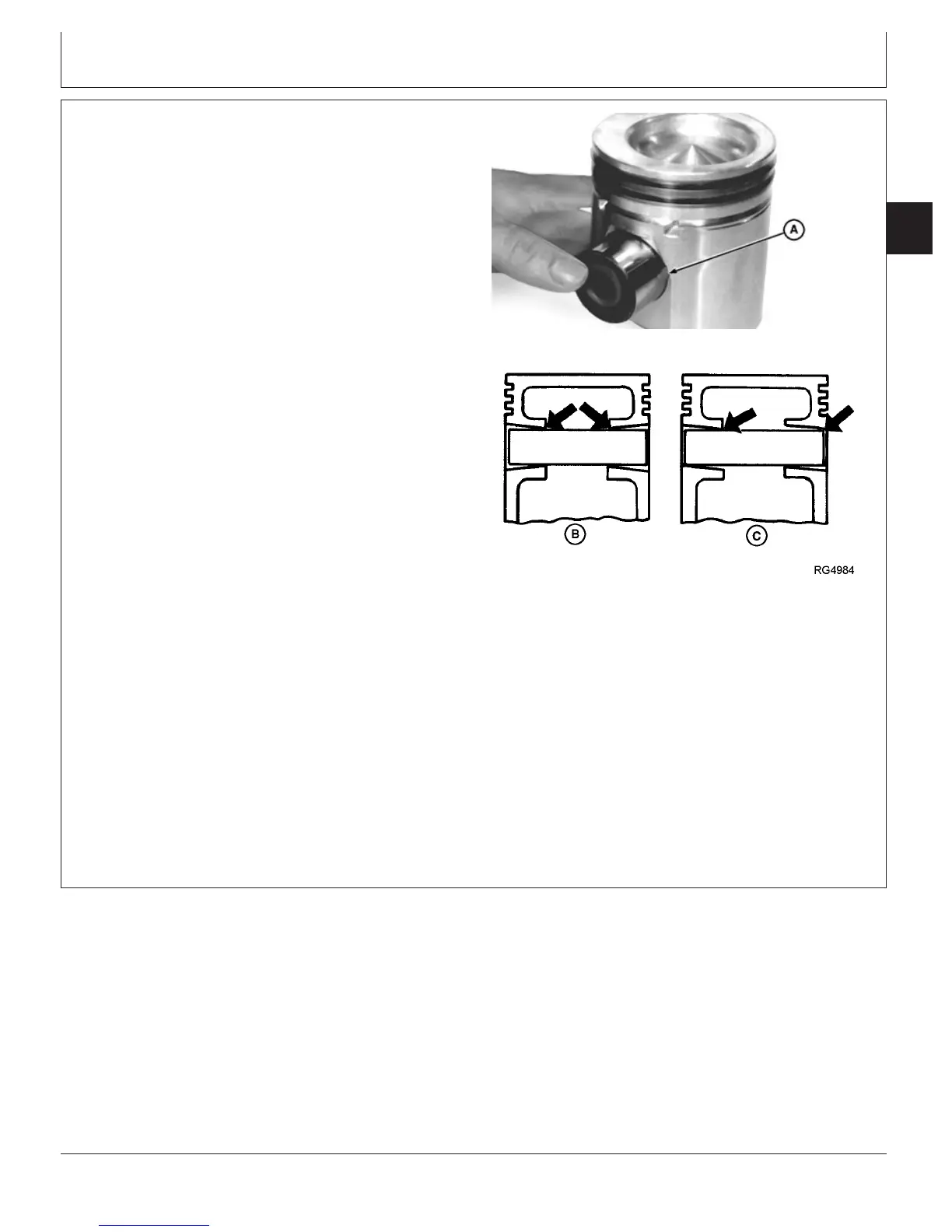

Installing Piston Pin

RG4984 –UN–05DEC97

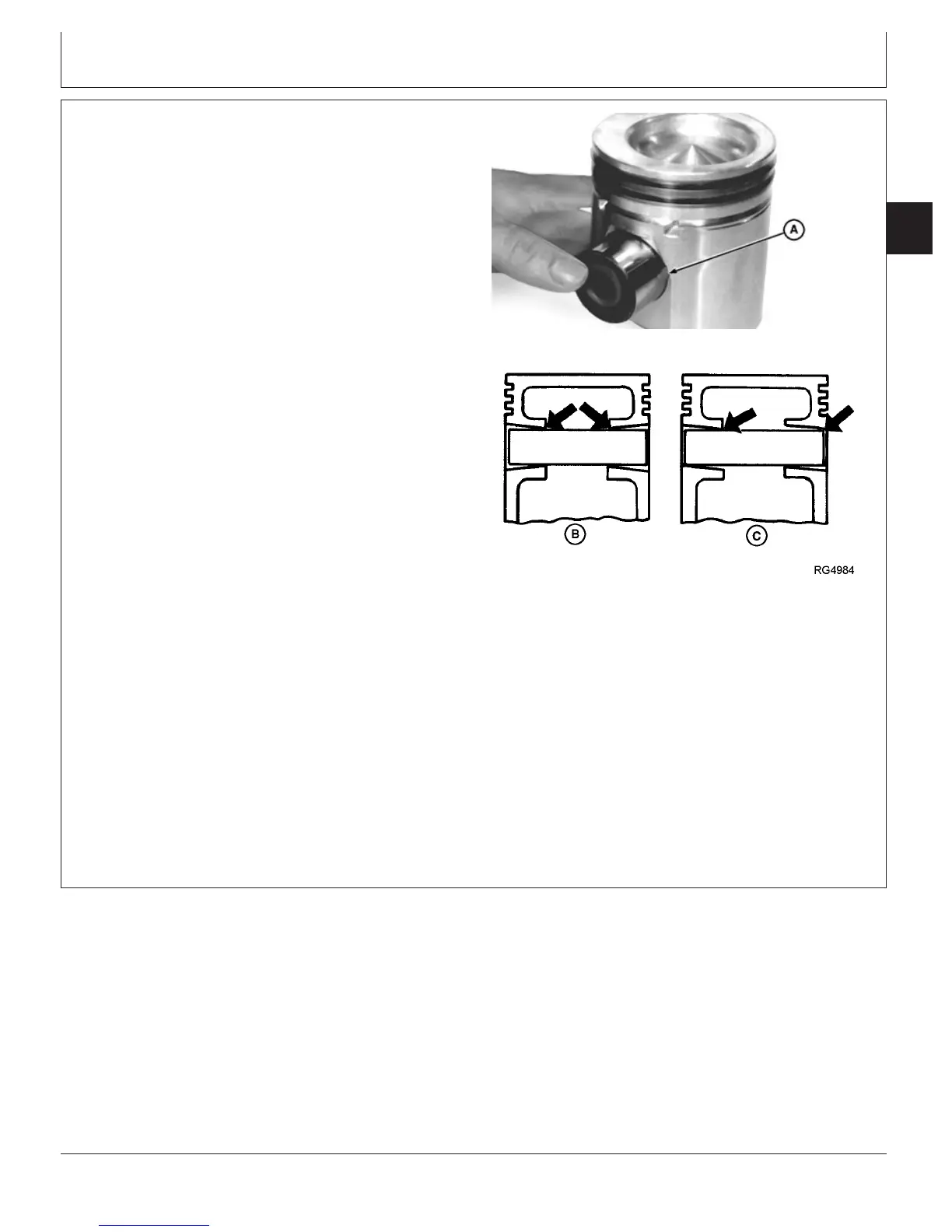

Piston Pin Bore Inspection

A—Pin

B—Tapered Bore

C—Opposite Side of Bore

NOTE: Piston pin must be in good condition and not worn

beyond specification given below.

1. Dip piston pin in clean engine oil.

NOTE: On 6125 engines, assemble piston crown and

skirt.

2. Install pin (A) through piston.

Pin should pass through piston using only light thumb

pressure.

3. Check taper in piston pin bore by inserting pin from

both sides. If pin enters freely, but binds in the center,

the bore could be tapered (B).

4. Insert pin in piston to check for bore alignment. Pin

should not “click” or need to be forced into bore on

opposite side (C).

5. Measure piston pin and piston bore and compare to

specifications. If either are not within specification,

replace pin, piston, and liner.

Specification

Piston Pin—OD 50.772—50.787 mm

(1.9989—1.9995 in.)

.........................................................

Piston Pin Bore in Piston

(6105)—ID 50.795—50.805 mm

(1.9998—2.0002 in.)

.................................................................

Piston Skirt Bushing (6125)—ID 50.798—50.808 mm

(1.9999—2.0003 in.)

...............................

Piston Crown Bushing (6125)—ID 50.810—50.825 mm

(2.0004—2.0010 in.)

............................

CTM100 (06APR04)

02-030-25

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=165

Loading...

Loading...