Cylinder Head and Valves

02

020

10

RG,RG34710,64 –19–21DEC00–1/2

Remove Rocker Arm Assembly

RG8262B –UN–06DEC97

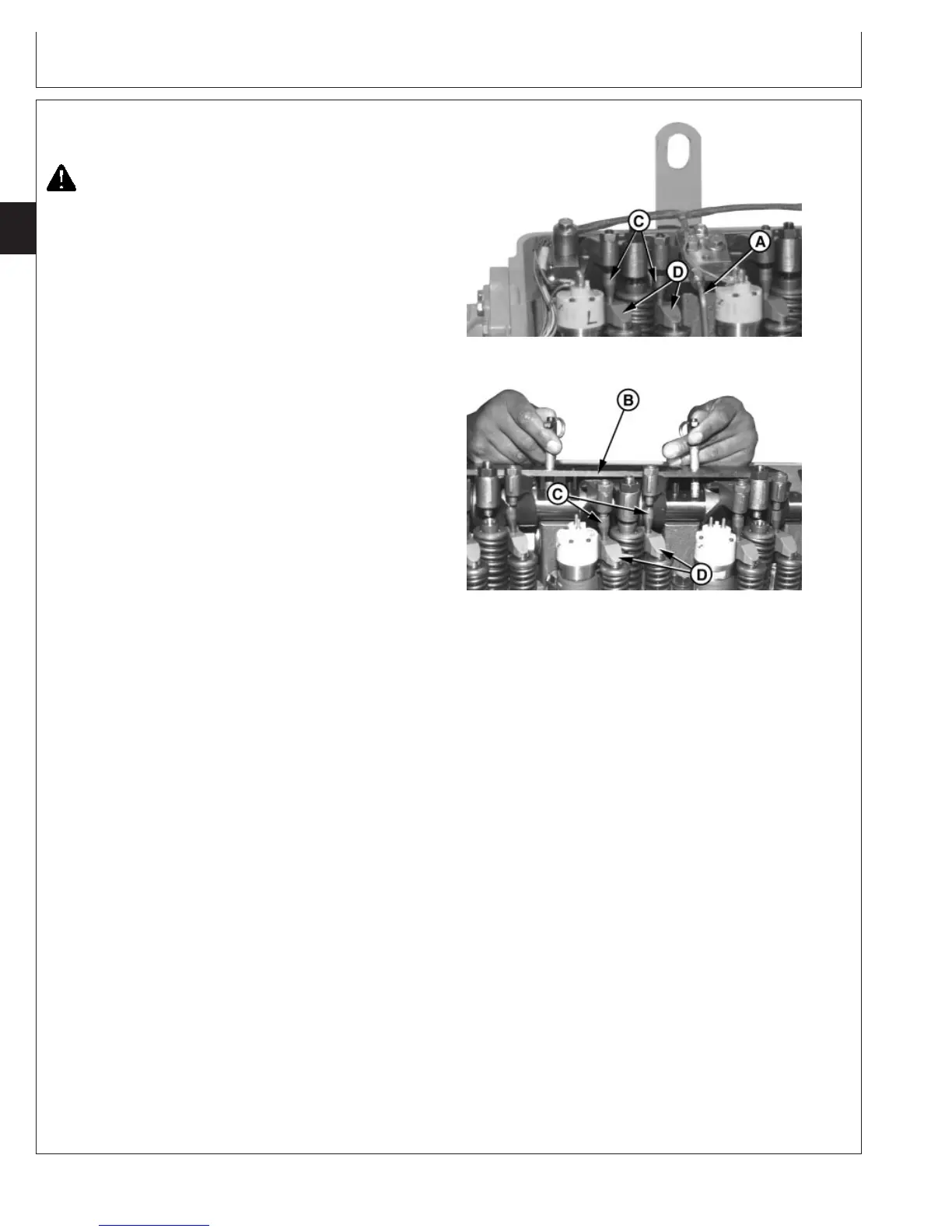

Removing Valve Bridge and Push Tubes

RG8459A –UN–21JUL99

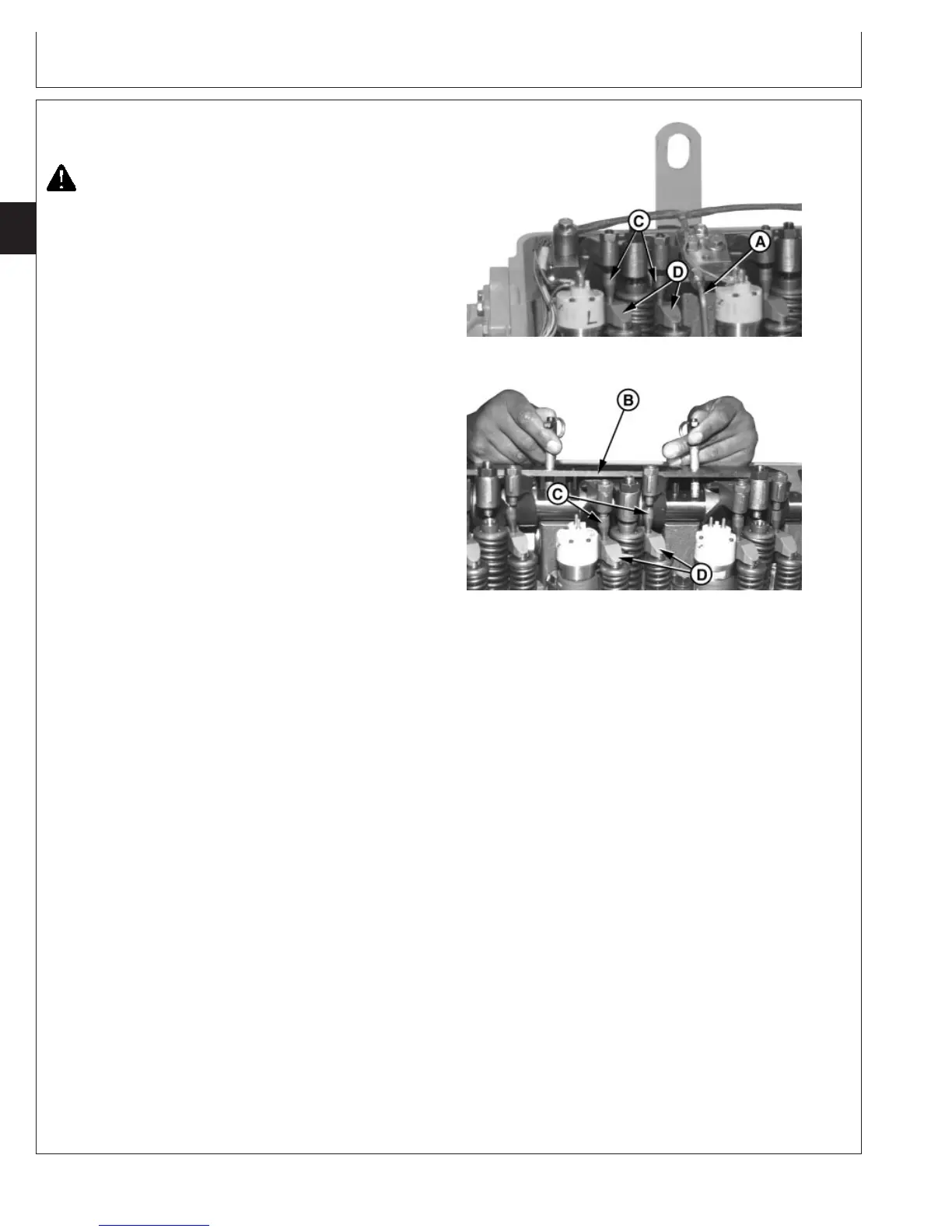

Removing Rocker Arm Assembly with JDG970A

A—Rocker Arm Shaft Oil Tubes (Dual Rail Fuel

System Only)

B—Rocker Arm Lifting Fixture

C—Push Tubes

D—Valve Bridges

CAUTION: After operating engine, allow exhaust

system to cool before servicing engine.

1. Remove rocker arm cover.

2. Lock camshaft and crankshaft at TDC of No.1

cylinder’s compression stroke.

3. Remove electronic unit injector wiring harness from

rocker arm shaft clamps.

IMPORTANT: ALWAYS loosen all intake, exhaust and

EUI rocker arm adjusting screws before

removal or installation of rocker arm

assembly to relieve pressure. This

allows for a more uniform rocker arm

cap screw clamp load and reduces the

possibility of damage to valve train

components.

Remove push tubes and valve bridges

immediately after relieving rocker arm

pressure. Push tubes can fall into oil

drain opening of cylinder head causing

oil pan removal to retrieve tubes.

4. Loosen EUI, intake, and exhaust valve rocker arm

adjusting screw lock nut and relieve pressure at all

locations.

5. Remove push tubes (C) and valve bridges (D) from all

valve stems.

6. Remove two rocker arm shaft oil tubes (A) (dual rail

system only). Remove rocker arm shaft hold-down

clamps.

IMPORTANT: Rocker arm shaft hold-down clamp cap

screws can not be reused. Use new cap

screws for reassembly.

7. Install shaft clamp cap screw in end hole of each

rocker arm shaft so that rocker arms do not slide off

shaft when lifted.

CTM100 (06APR04)

02-020-10

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=82

Continued on next page

Loading...

Loading...