Observable Diagnostics and Tests

DPSG,RG40854,357 –19–06NOV00–2/2

If timing pin does not enter crankshaft timing slot,

crankshaft MUST BE timed to camshaft. See CHECK

AND ADJUST CAMSHAFT-TO-CRANKSHAFT TIMING in

Section 02, Group 050.

04

150

24

DPSG,RG40854,466 –19–07NOV00–1/1

Check Crankshaft Position Sensor Depth

RG10290 –UN–24AUG99

Crankshaft Position Sensor

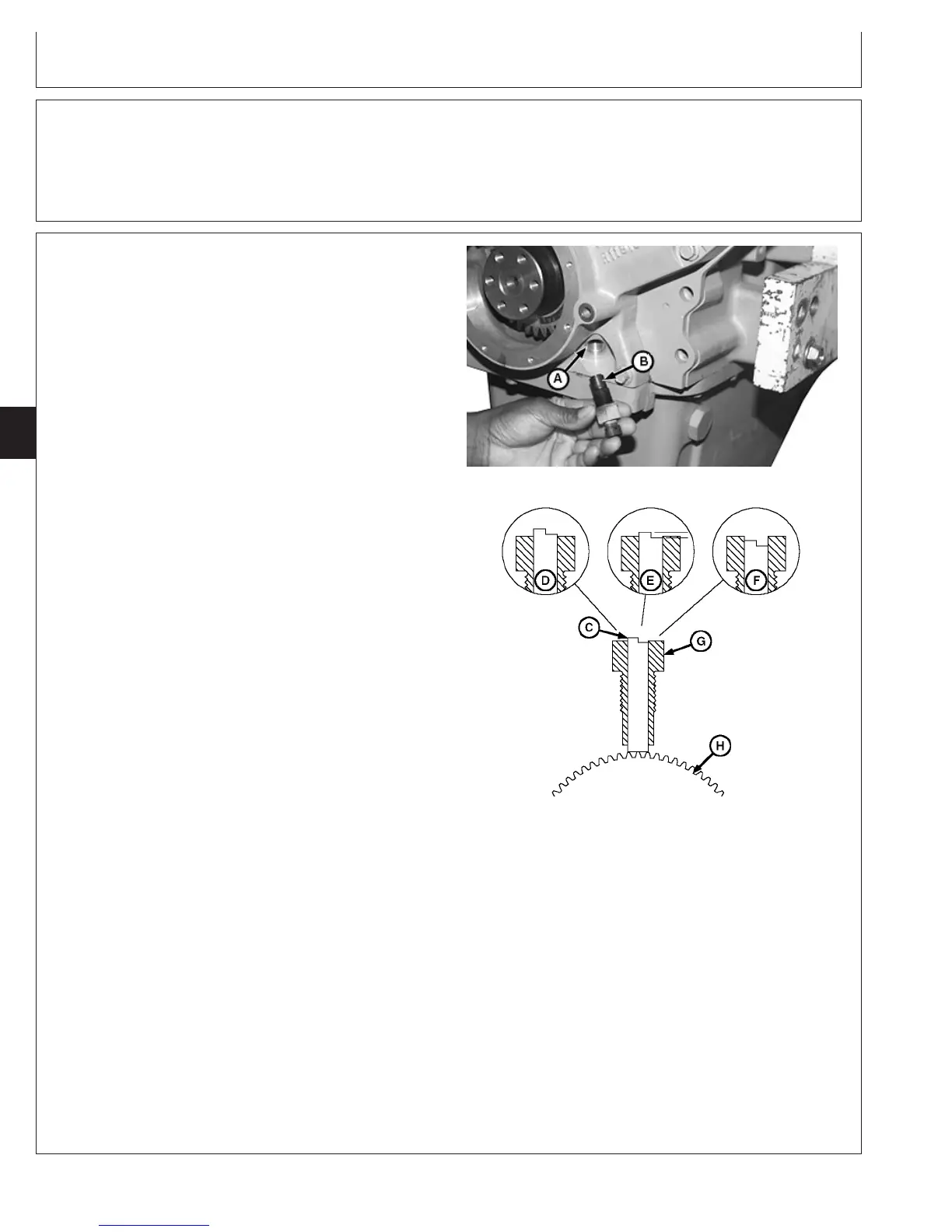

RG10380 –UN–19OCT99

Using JDG1334 Depth Checking Tool

A—Machined Mounting Surface (Spotface)

B—Crankshaft Position Sensor

C—Pin (In JDG1334 Depth Tool)

D—Sensor Depth Low (Shim Required)

E—Sensor Depth Correct (No Shim Required)

F—Sensor Depth too High (Requires

Investigation)

G—JDG1334 Depth Checking Tool

H—Crankshaft Timing Wheel

NOTE: Crankshaft vibration damper and front seal shown

removed

The ECU monitors the position of the crankshaft and

camshaft to determine piston position and the optimum

time to start and stop injecting fuel. This crank sensor

sends the crank position to the ECU.

1. Disconnect crankshaft position sensor wiring

connector.

2. Remove sensor (B) from timing gear cover.

3. Install JDG1334 Tool (C) in sensor bore in timing gear

cover until the tool is hand tight within the timing gear

cover.

4. Push in on pin (C) until it contacts crankshaft timing

wheel (H).

5. Check position of pin end in relation to end of tool as

shown in (D, E, F)

• If pin’s lower shoulder extends above end of tool (D),

add one R60756 shim to sensor.

• If pin’s lower shoulder is within range of marks (E),

no shim is required on sensor.

• If pin is below end of tool (F), call DTAC for

assistance.

6. Grease O-ring with JDT405 High Temperature Grease

7. Install sensor in timing gear cover and tighten to

specification.

Specification

Crankshaft Position Sensor—

Torque 14 N•m (10 lb-ft).............................................................................

CTM100 (06APR04)

04-150-24

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=372

Loading...

Loading...