Engine Rebuild Guide, Break-In and Tune-Up

02

010

15

RG,RG34710,52 –19–21AUG02–3/3

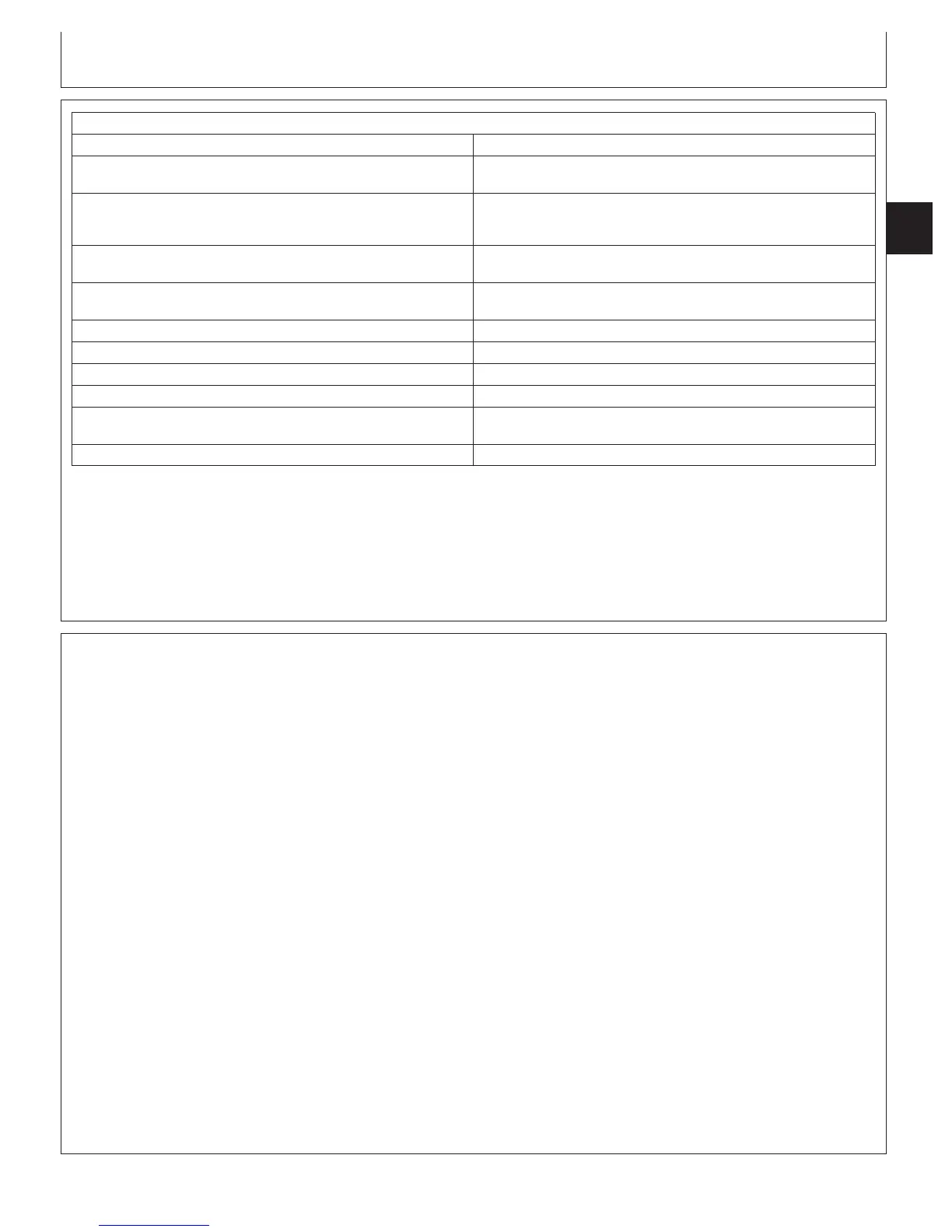

ENGINE ASSEMBLY SEQUENCE—CONTINUED

Procedure Reference

Install water manifold/thermostat housing assembly. See REMOVE AND INSTALL THERMOSTAT HOUSING in Group

070.

Install oil filter housing/oil cooler assembly. See INSTALL OIL COOLER/OIL FILTER VALVE HOUSING

ASSEMBLY OR OIL COOLER COVER/VALVE HOUSING

ASSEMBLY in Group 060.

Install exhaust manifold assembly. See REMOVE, INSPECT AND INSTALL EXHAUST MANIFOLD in

Group 080.

Install turbocharger. Connect all turbocharger oil lines and See INSTALL TURBOCHARGER in Group 080.

intake/exhaust piping.

Install alternator. See REMOVE AND INSTALL ALTERNATOR in Group 100.

Install compressor. See CTM67, OEM Engine Accessories.

Install fan drive, fan and fan belt. See Group 070.

Mount engine into vehicle. See vehicle repair manual.

Flush cooling system. Fill engine systems with recommended fuel, See FLUSH AND SERVICE COOLING SYSTEM in Section 01,

lubricant, and coolant. Group 002.

Perform engine break-in and normal standard performance checks. See PERFORM ENGINE BREAK-IN in this group.

RG,RG34710,1053 –19–05DEC00–1/1

Engine Break-In Guidelines

Engine break-in should be performed after overhaul or

when the following repairs have been made:

Main bearings, rod bearings, crankshaft, or any

combination of these parts have been replaced.

Pistons, rings, or liners have been replaced.

Rear crankshaft oil seal and wear sleeve have been

replaced. (Primary objective is to see if oil seal still leaks).

Cylinder head has been removed.

Electronic unit injectors have been removed or critical

adjustments have been made while they are on the

engine. (Primary objective of break-in is to check power).

CTM100 (06APR04)

02-010-15

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=63

Loading...

Loading...