Crankshaft, Main Bearings, and Flywheel

02

040

2

RG,RG34710,149 –19–23OCT00–1/1

Inspect Crankshaft Vibration Damper

RG8536 –UN–20MAY98

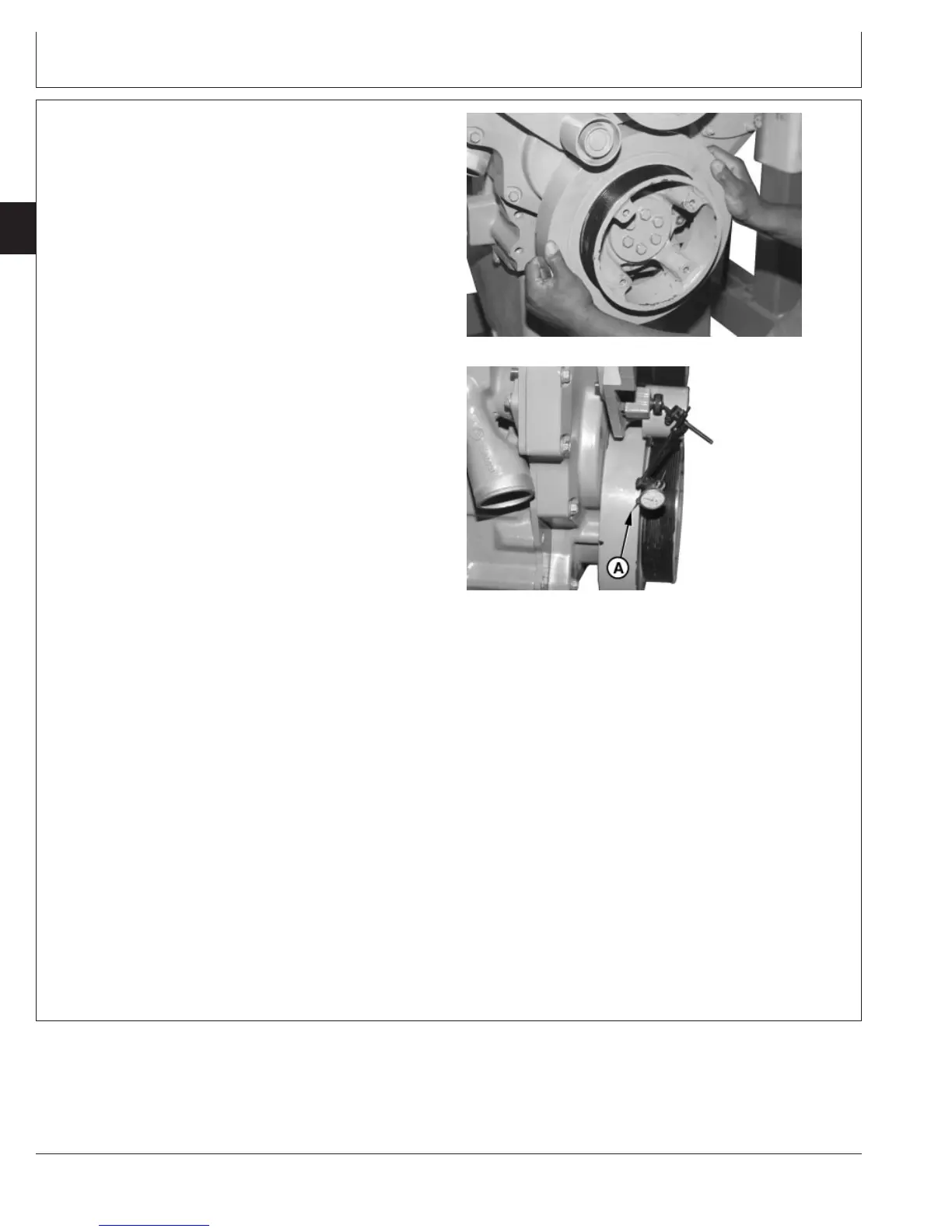

Checking Damper Rotation

RG8537 –UN–10DEC97

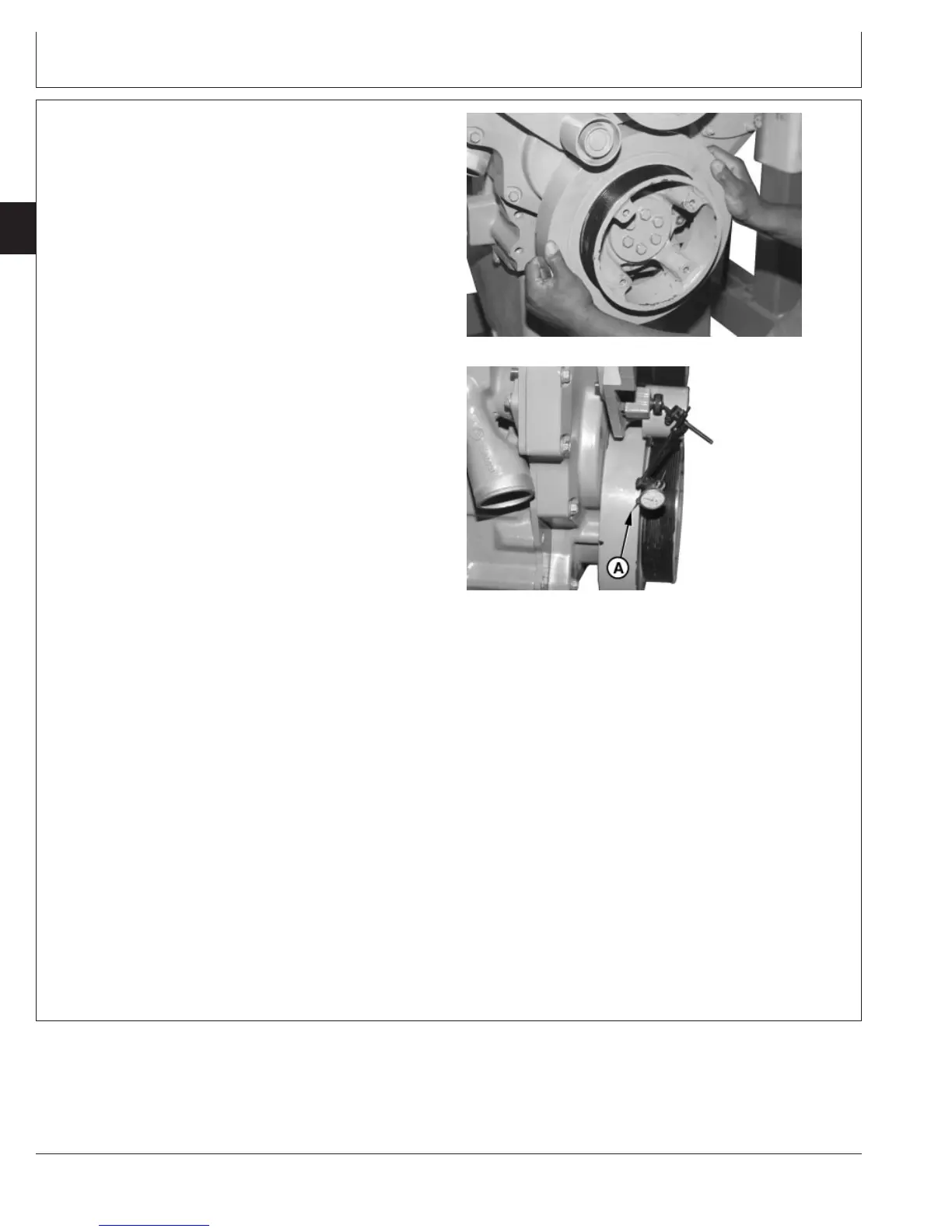

Measuring Damper Radial Runout

A—Probe

Refer to your machine operator’s manual for

recommended vibration damper inspection frequency.

1. Remove V-belt (shown removed).

IMPORTANT: The vibration damper assembly is not

repairable and should be replaced every

5 years or 4500 hours, whichever

occurs first.

ALWAYS replace vibration damper

whenever crankshaft is replaced and at

major engine overhaul. Also replace

damper when a short block, complete

block, or remanufactured basic engine

is installed.

2. Carefully inspect vibration damper for torn or split

rubber protruding from front and back of assembly.

3. Grasp vibration damper with both hands and attempt to

turn it in both directions. If rotation is felt, damper is

defective and should be replaced.

4. Check vibration damper radial runout by positioning a

dial indicator so probe (A) contacts damper OD.

5. With engine at operating temperature, rotate crankshaft

using JDG820 Flywheel Turning Tool.

6. Note dial indicator reading. Replace vibration damper if

radial runout exceeds specifications.

Specification

Vibration Damper—Maximum

Radial Runout 0.76 mm (0.030 in.).............................................................

CTM100 (06APR04)

02-040-2

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=198

Loading...

Loading...