Cylinder Block, Liners, Pistons, and Rods

02

030

16

RG,RG34710,110 –19–03AUG99–1/2

Visually Inspect Cylinder Liners

RG4643 –UN–05DEC97

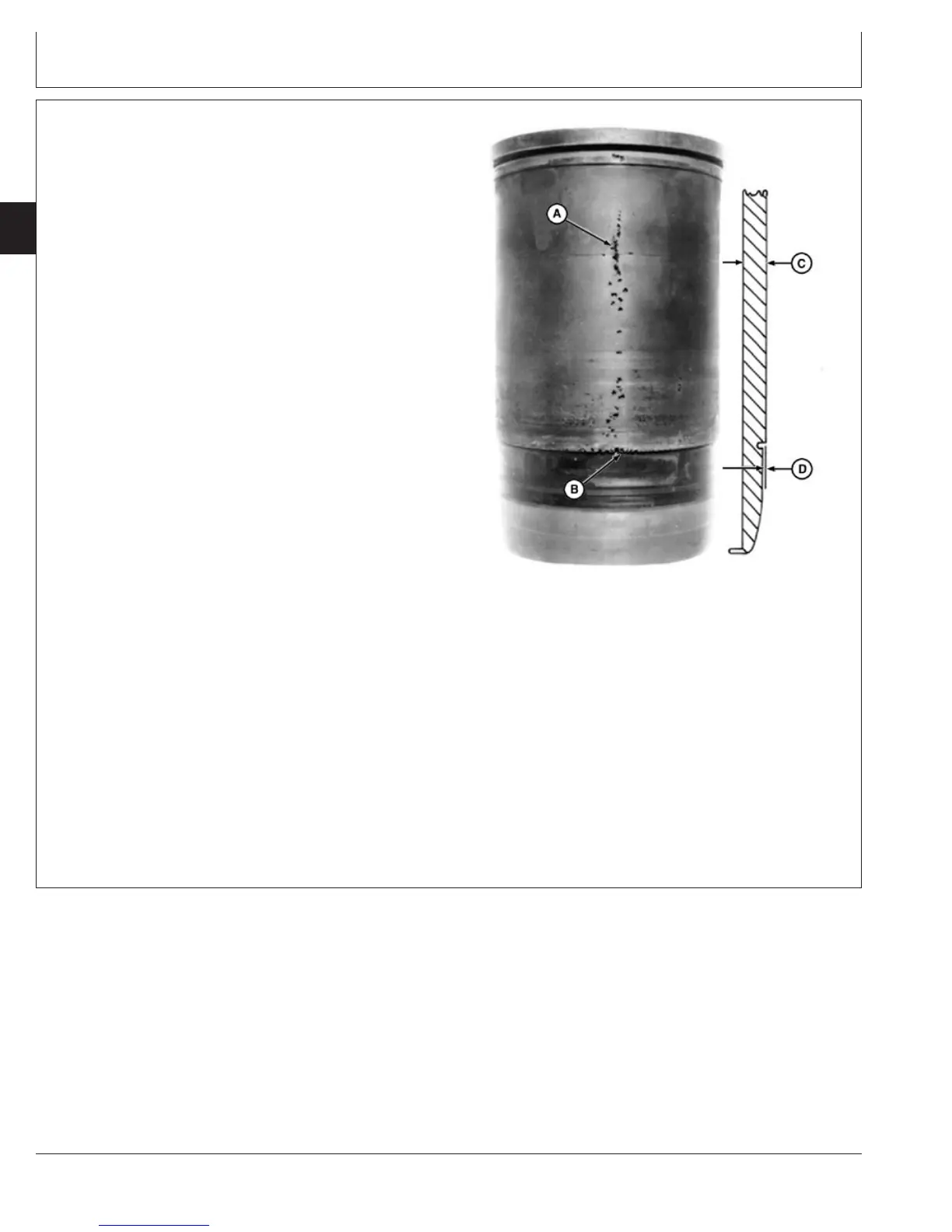

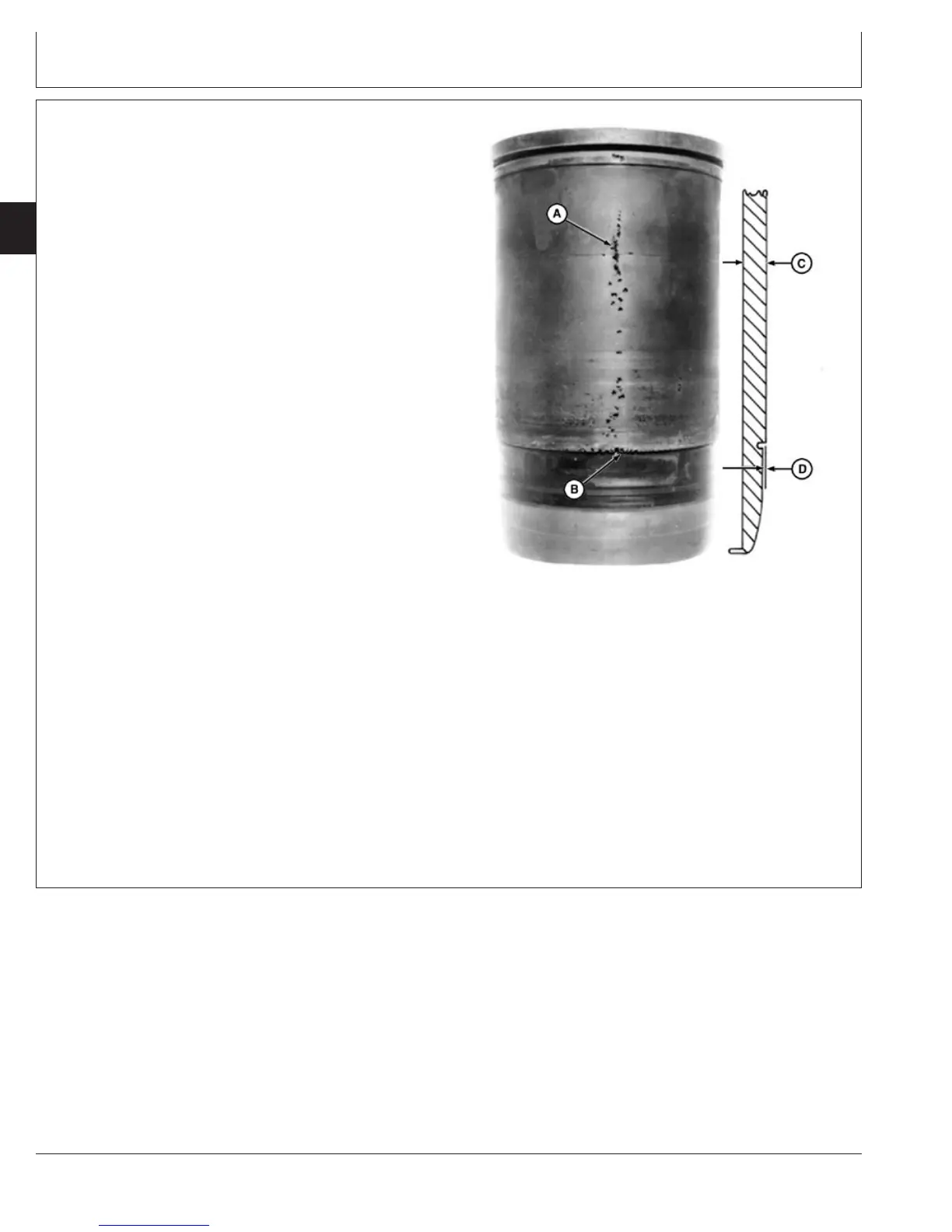

Liner Visual Inspection

A—Liner Pitting

B—Erosion

C—Pitting Depth Is One-Half Liner Thickness

D—Erosion Depth Is One-Half Packing Step

IMPORTANT: If pitting has occurred, check condition

of coolant.

1. Inspect exterior length of liner for pitting (A). Check

packing step for erosion (B). If pitting or erosion is

observed, measure the depth of pits and erosion with a

fine wire or needle.

Replace piston and liner if:

• Pitting depth is one-half liner thickness (C) or more.

Specification

Cylinder Liner Wall—Thickness 9.39—9.43 mm (0.370—0.371 in.)..........

• Erosion depth is one-half packing step (D) or more.

Specification

Cylinder Liner Packing Step—

Dimension 2.14—2.30 mm (0.084—0.090 in.)............................................

NOTE: Liners are reusable if the depth of pits or erosion

is less than one-half the amount specified. When

installing these liners, rotate 90

°

from original

position. The liners should be deglazed and ring

sets installed on pistons.

Continued on next page

CTM100 (06APR04)

02-030-16

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=156

Loading...

Loading...