Lubrication System

02

060

13

RG,RG34710,216 –19–24SEP02–2/2

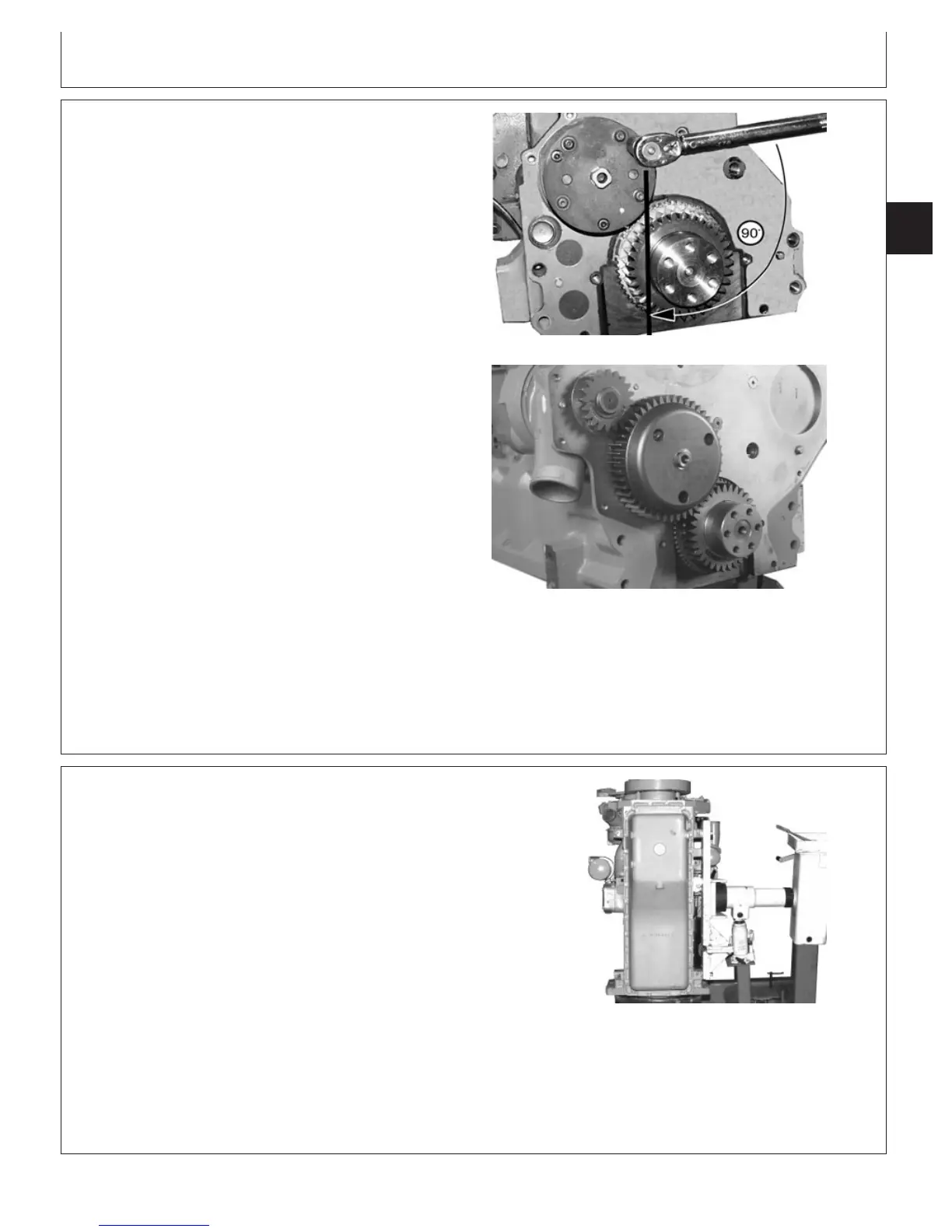

RG12611 –UN–30AUG02

90

°

Torque Turn

RG8256 –UN–21MAY98

Installing Oil Pump Drive Gear

4. Second: Starting with first cap screw tightened, apply

90° torque turn to each cap screw.

Specification

Oil Pump-to-Block Cap Screws—

Torque Turn 90° (1/4 Turn)..........................................................................

5. Rotate input shaft full 360° after pump installation. If

shaft does not turn freely for full 360°, remove pump

and determine cause.

6. Apply TY6333 or TY6347 High Temperature Grease to

ID of oil pump drive gear bushing.

7. Install oil pump gear with bushing over oil pump

housing; align input shaft with opening in gear.

8. Install external snap ring in groove of input shaft.

9. Check oil pump drive gear-to-idler gear backlash.

Specification

Oil Pump Drive Gear-to-Idler

Gear—Backlash 0.25 mm (0.010 in.)..........................................................

10. Install timing gear train cover and complete final

assembly. (See INSTALL TIMING GEAR COVER in

Group 040.)

RG,RG34710,217 –19–30SEP97–1/1

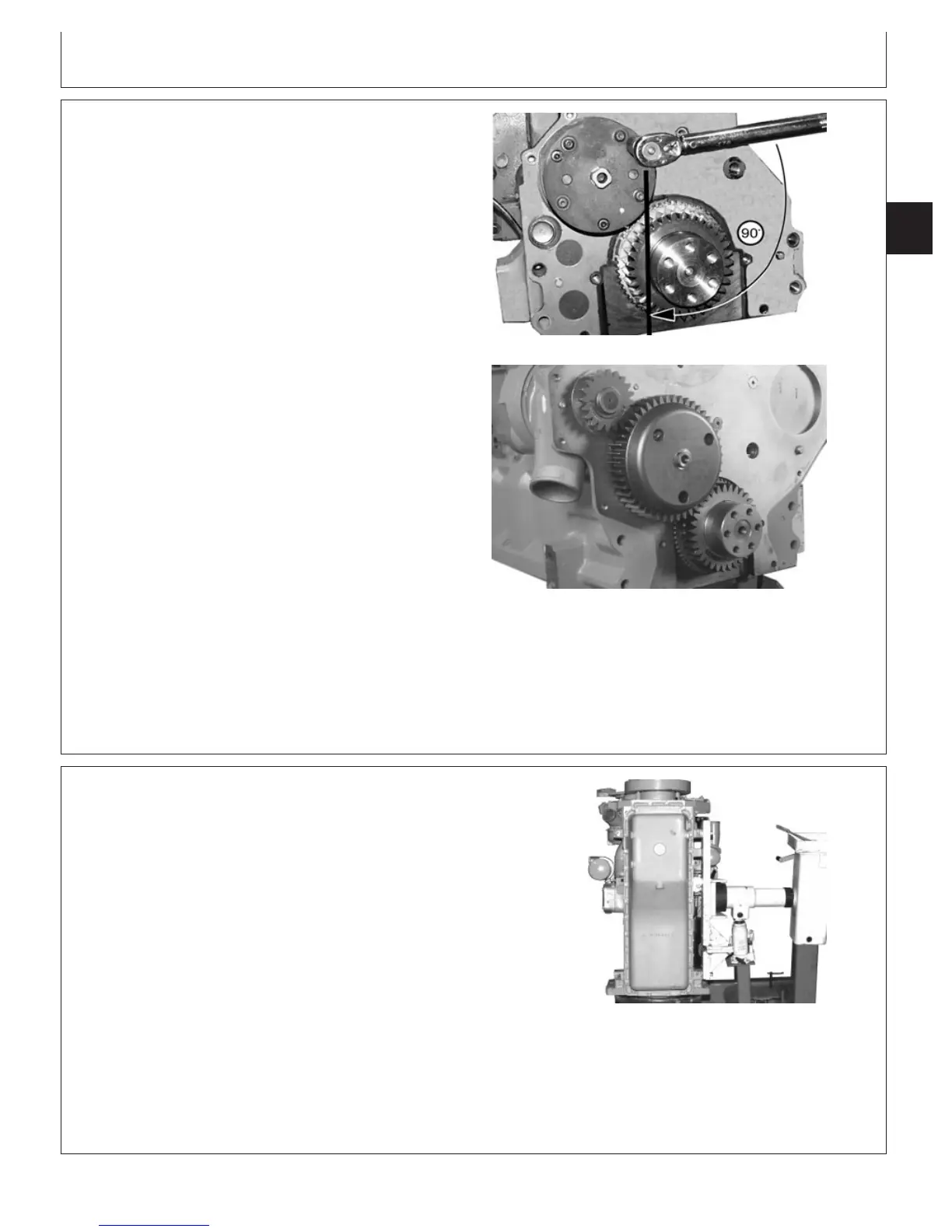

Remove Engine Oil Pan

RG8819 –UN–20MAY98

Removing Oil Pan

1. Disconnect turbocharger oil inlet line. Remove oil pan

drain plug and drain all engine oil.

NOTE: It may be necessary to tap oil pan with a rubber

or plastic dead-blow hammer to free oil pan from

gasket seal.

2. Remove all 30 oil pan cap screws and remove oil pan

from cylinder block.

3. Remove all gasket material from oil pan and cylinder

block gasket sealing surfaces.

4. Clean all oil from oil pan and cylinder block sealing

surfaces and dry completely.

CTM100 (06APR04)

02-060-13

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=281

Loading...

Loading...