Cylinder Block, Liners, Pistons, and Rods

02

030

11

RG,RG34710,108 –19–13AUG99–1/2

Measure Cylinder Liner Standout (Height

Above Block)

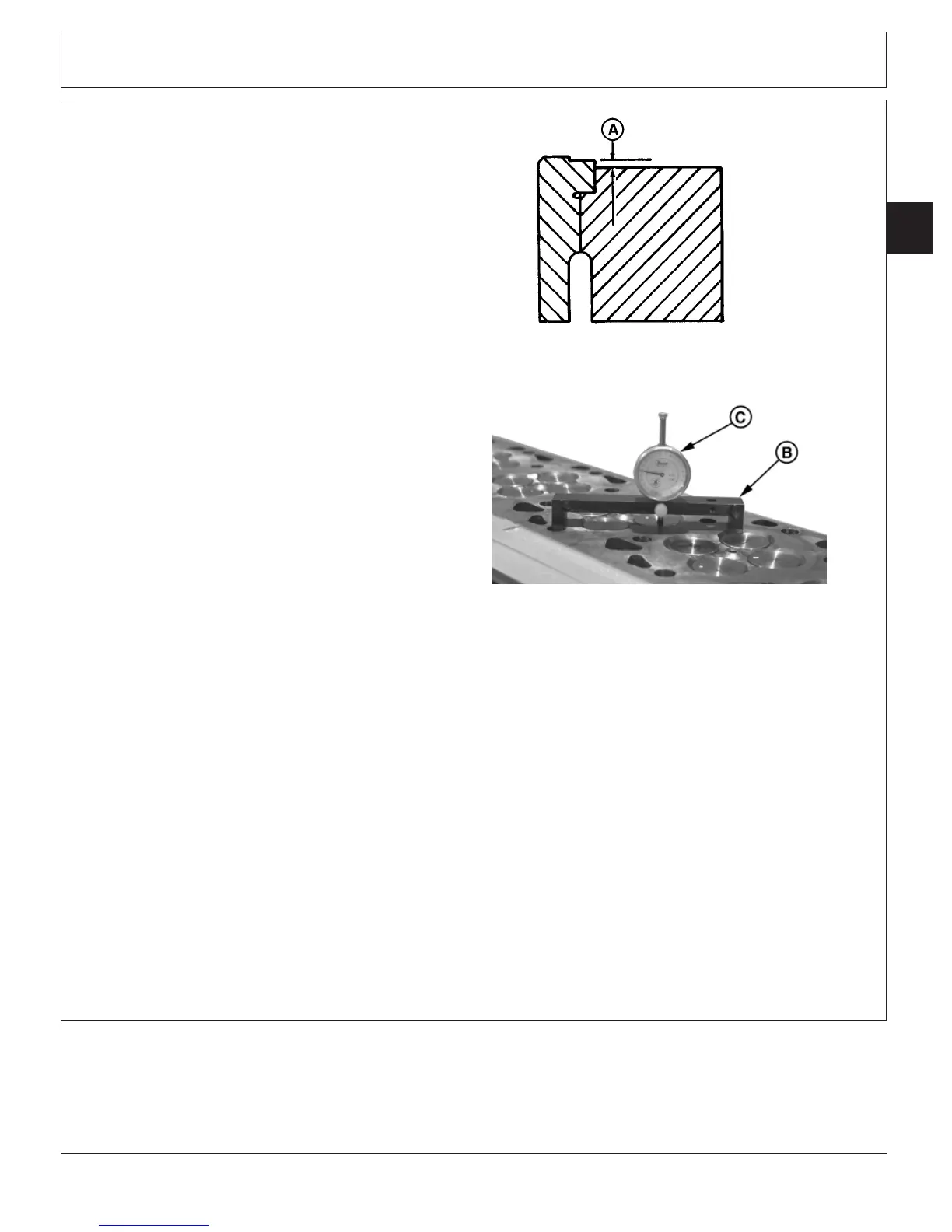

RG6439 –UN–03NOV97

Liner Standout

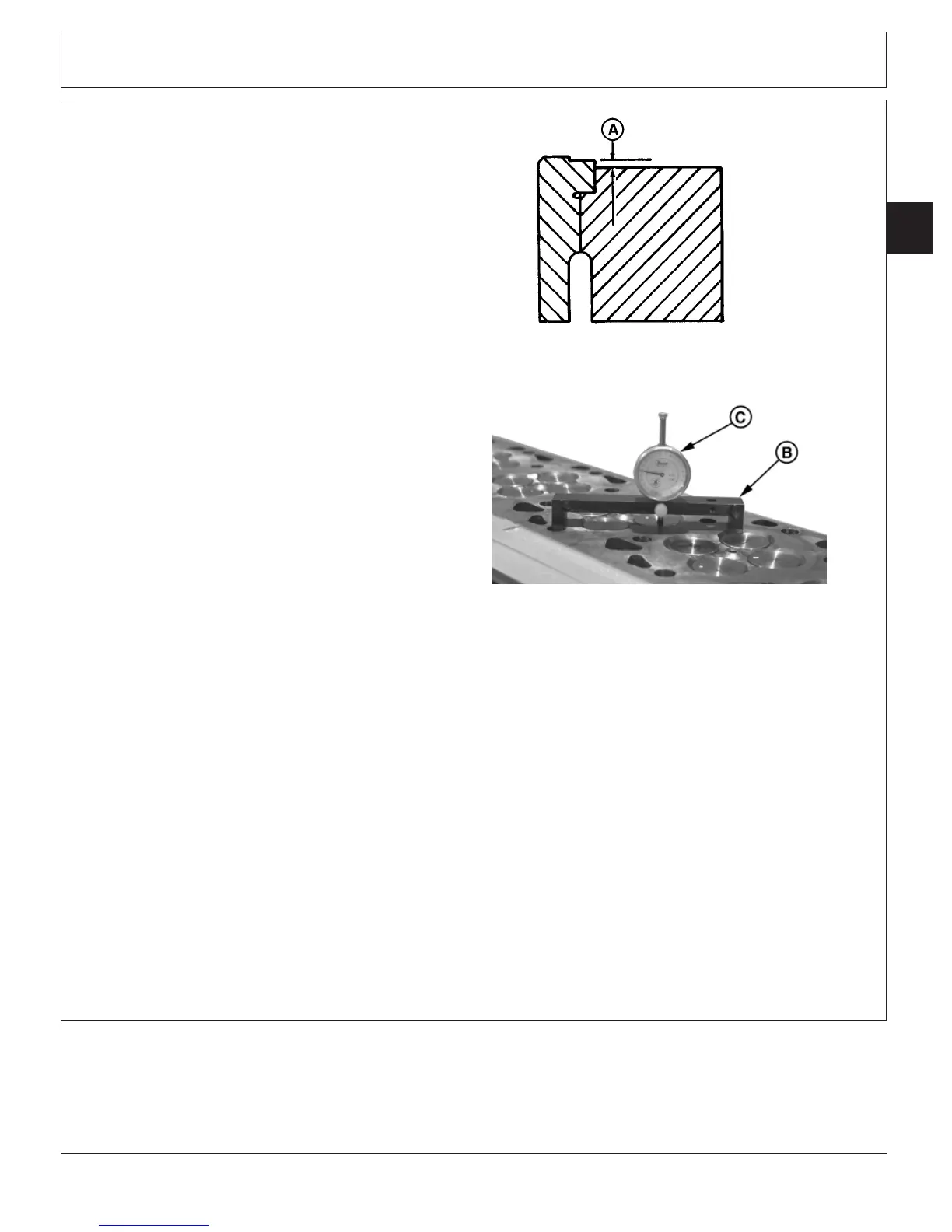

RG8330B –UN–09DEC97

Measuring Liner Standout

A—Liner Height

B—JDG451 Gauge

C—KJD10123 Gauge

IMPORTANT: Remove all gasket material, rust, carbon

and other foreign material from top

deck of cylinder block. Use compressed

air to remove all loose foreign material

from cylinders and top deck.

NOTE: Liners having obvious defects must be replaced

as a matched piston and liner set.

1. Bolt liners down in seven locations using cap screws

and washers. (See REMOVE PISTONS AND

CONNECTING RODS, earlier in this group.) Tighten

cap screws to 68 N•m (50 lb-ft).

Specification

Cylinder Liner Cap Screws (For

Checking Liner Standout)—

Torque 68 N•m (50 lb-ft).............................................................................

2. Using JDG451 Gauge (B) along with D17526CI

(English scale) or D17527CI (metric scale) Dial

Indicator or KJD10123 Gauge (C), measure liner height

(A) for all cylinders.

3. Measure each liner in four places at approximately 1,

5, 7, and 11 o’clock positions as viewed from rear of

engine (flywheel end). Record all measurements by

cylinder number.

NOTE: Variations in measurement readings may occur

within one cylinder and/or between adjacent

cylinders.

4. If liner standout is below specification, measure liner

flange thickness. (See MEASURE LINER FLANGE

THICKNESS later in this group.) Measure liner

counterbore depth in cylnder block. (See INSPECT

AND CLEAN CYLINDER BLOCK, later in this group.)

Continued on next page

CTM100 (06APR04)

02-030-11

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=151

Loading...

Loading...