Cylinder Block, Liners, Pistons, and Rods

02

030

35

RG,RG34710,123 –19–13AUG99–2/2

RG4924 –UN–20NOV97

Inspecting Rod Piston Pin Bushing Bore

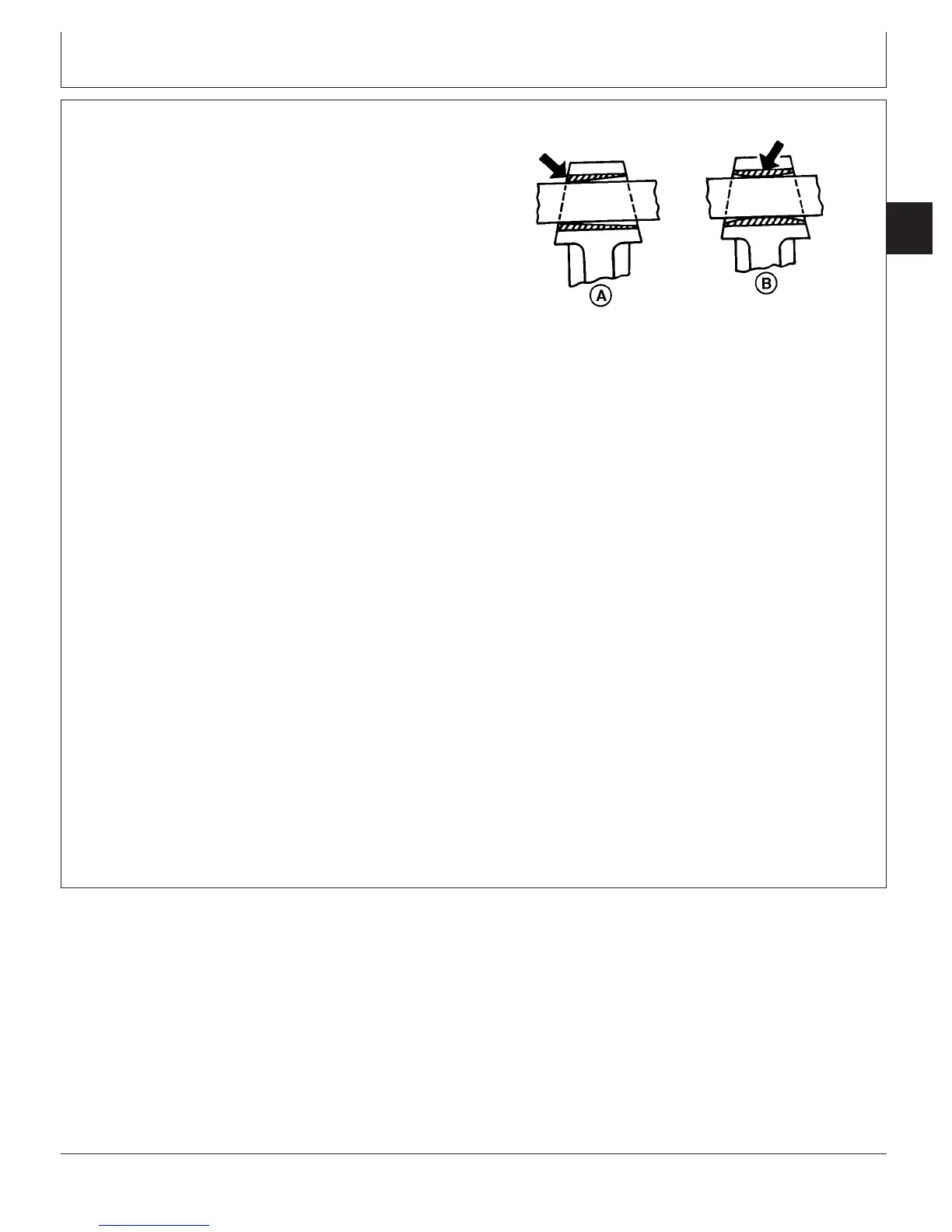

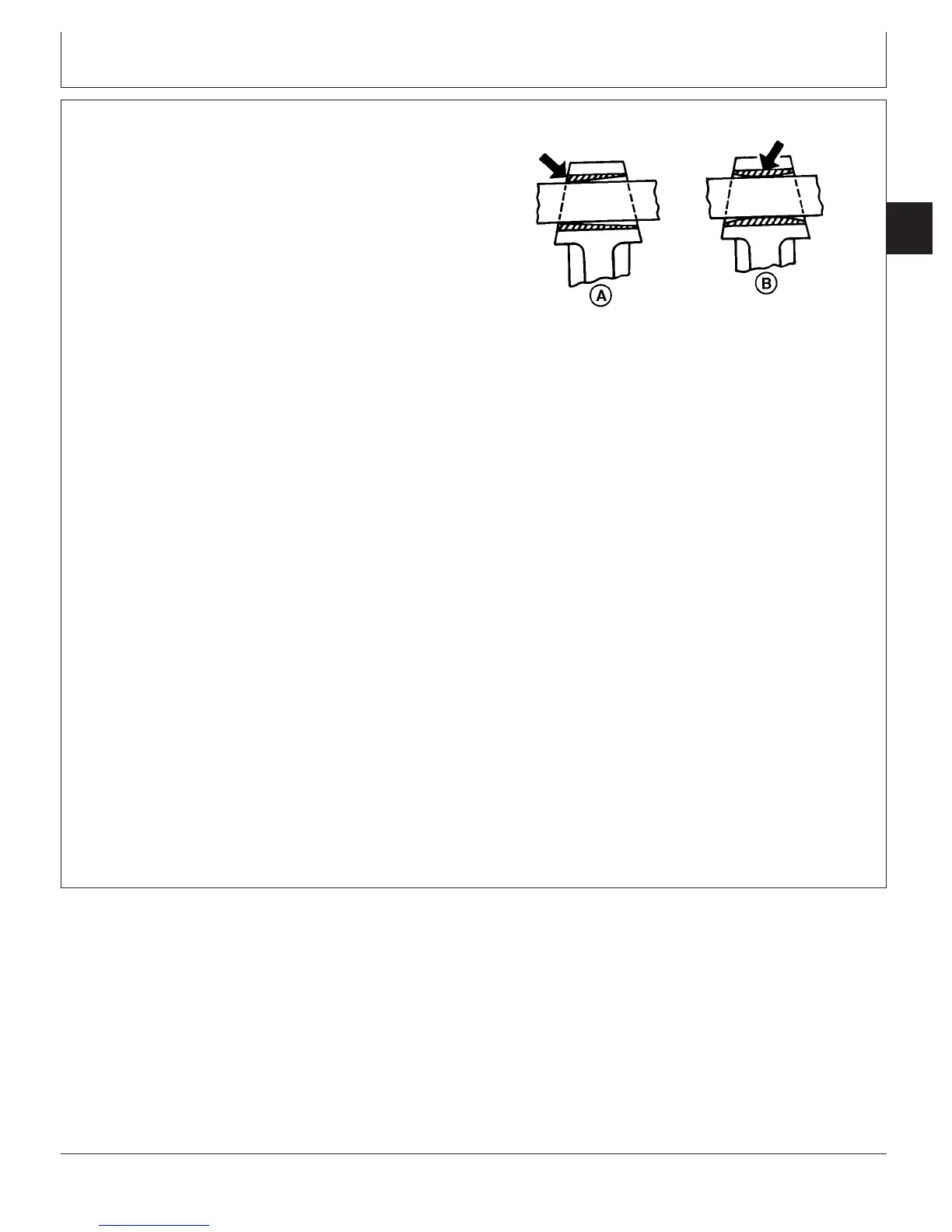

A—Tapered Bore

B—Bell-Mouthed Bore

4. Insert pin from either side of rod bushing. If pin is free

on one end, but tight on the other, the bore could be

tapered (A). If pin enters freely from both sides, but is

tight in the center, bore is bell-mouthed (B).

5. Inspect piston pin bushing lubrication hole in rod for

damage, excessive wear or contaminants.

6. Measure pin bushing ID for specified clearance.

Specification

Piston Pin—OD 50.772—50.787 mm

(1.9989—1.9995 in.)

.........................................................

Rod Pin Bore Without Bushing—

ID 55.529—55.555 mm

(2.1862—2.1872 in.)

...............................................................................

Installed Rod Pin Bushing (Before

Boring)—ID 50.729—50.781 mm

(1.9972—1.9992 in.)

................................................................

Installed Rod Pin Bushing (After

Boring)—ID 50.805—50.830 mm

(2.0002—2.0012 in.)

................................................................

Piston Pin Bushing Bore—

Out-of-Round 0.038 mm (0.0015 in.)..........................................................

Piston Pin-to-Bushing—Oil

Clearance 0.017—0.059 mm

(0.0007—0.0023 in.)

......................................................................

Max. Acceptable Wear 0.076 mm (0.0030 in.)...........................................

Press Fit of Bushing in Rod Pin

Bore—Press Fit 0.100—0.163 mm

(0.0039—0.0064 in.)

.............................................................

7. If necessary, remove and replace piston pin bushing.

(See REMOVE PISTON PIN BUSHING, CLEAN, AND

INSPECT BUSHING BORE in this group.)

CTM100 (06APR04)

02-030-35

P

OWER

T

ECH

10.5 L & 12.5 L Diesel Engines

040604

PN=175

Loading...

Loading...