Section 16 : SUSPENSION

PA1562

14

4. Check the radial position of the pitman arm

in relation to the sector shaft prior to

removal of pitman arm.

5. Add reference marks to the arm and shaft if

necessary to ensure correct alignment at

reassembly.

6. Use a puller to remove pitman arm.

3.5 PITMAN ARM INSTALLATION

1. Position pitman arm on sector gear shaft

with reference marks aligned.

2. Install fixing nut. Tighten nut to 400-450 lbf-ft

(545-610 Nm).

NOTE

Use a new nut if the previously removed nut

was punched.

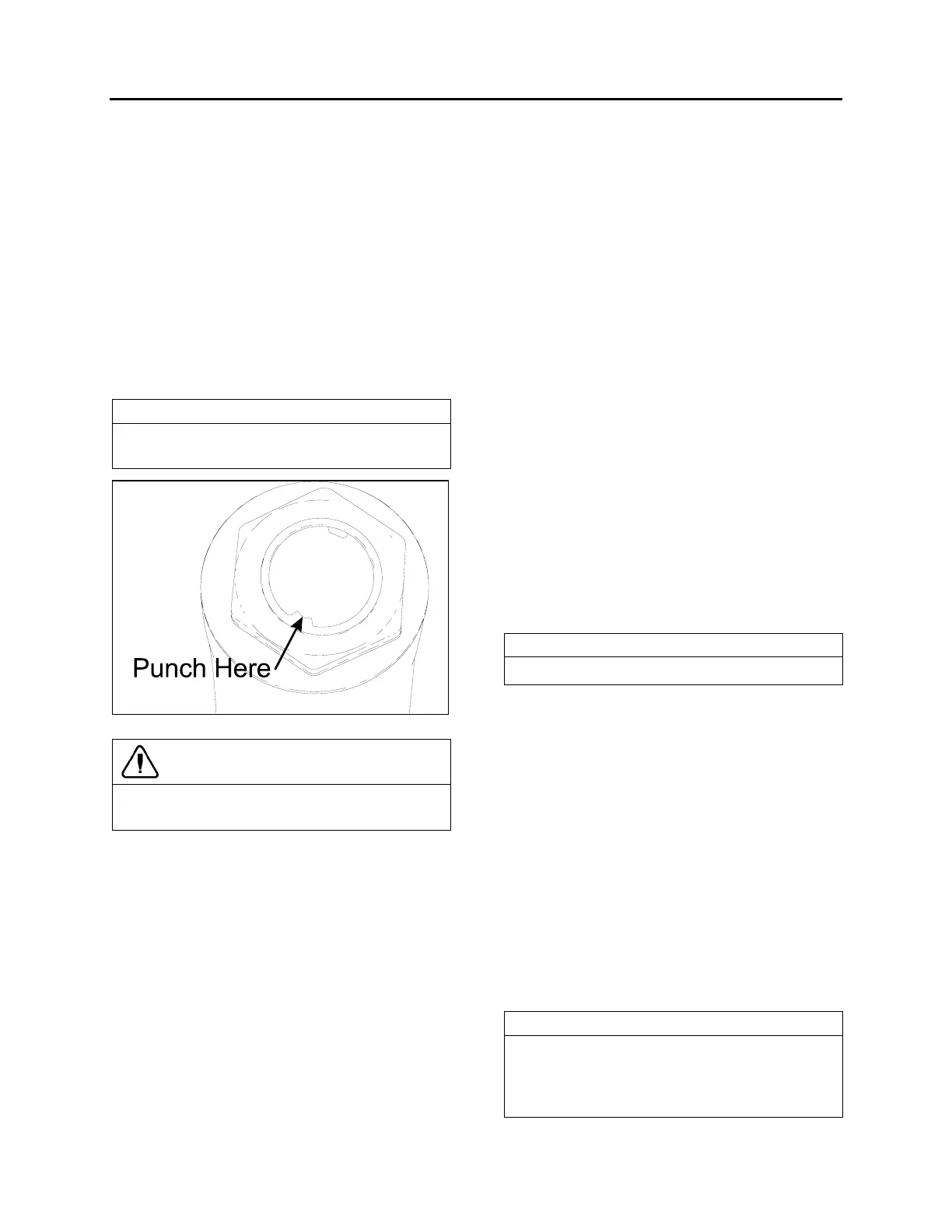

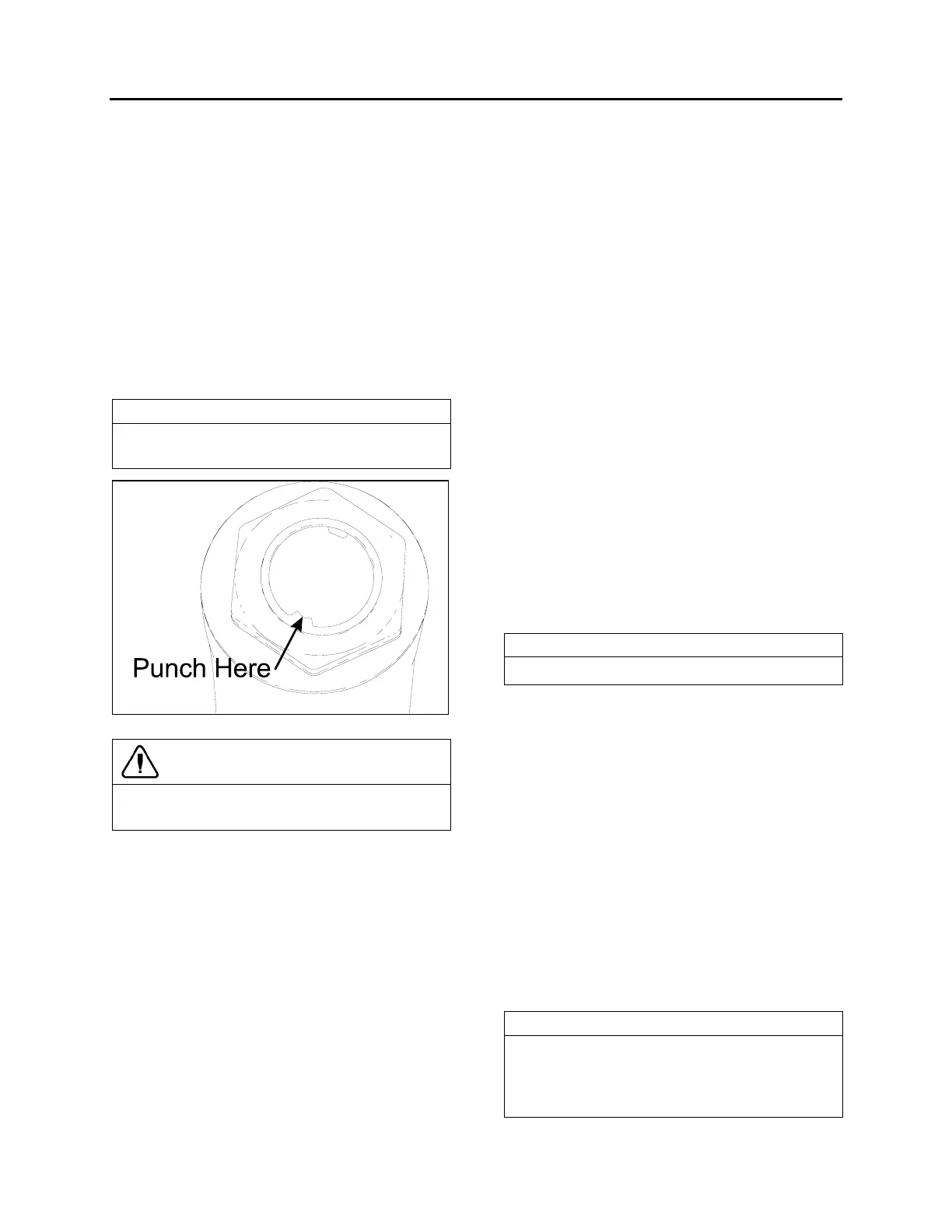

FIGURE 18: FIXING NUT PUNCH MARK

16098

CAUTION

Lock nut with sector shaft using a punch mark

into the groove (Refer to figure 18).

3. Connect drag link to pitman arm. Install

washers. Tighten nut to 160-215 lbf-ft (220-

290 Nm). Advance nut to next alignment

cotter pin slot and install a new cotter pin.

3.6 DRAG LINK

Drag link assembly consists of three parts; a

drag link and two end assemblies. Both end

assemblies are identical and they are retained

on the drag link with a clamp bolt and nut.

Stud nuts at the pitman arm and bell crank ends

of the drag link must be kept tight or hole at ball

stud end of drag link and hole in pitman arm

may become enlarged as a result of excessive

looseness. Subsequent tightening of stud nuts

may draw studs too far into holes and dust cover

parts may become damaged which can result in

component failure.

Drag link end sockets are equipped with

lubrication fittings and should be lubricated as

directed in "Lubrication Fittings" in this section.

3.6.1 Adjustment

It should not be necessary to alter the length of

the drag link except when a new link is installed

or when removable end assembly has been

replaced. If drag link adjustment is necessary,

proceed as follows:

1. Position front wheels in straight ahead

position.

2. Center steering gear as previously

explained in paragraph "3.3 Steering

Linkage Adjustment".

3. Remove cotter pin and stud from drag link at

bell crank. Locate centerline of vehicle and

center of relay rod. With center of relay rod

aligned with centerline of vehicle, loosen

clamp bolt at socket end (bell crank end) of

drag link and adjust length of socket end

assembly to fit in boss of bell crank.

NOTE

Do not change position of pitman arm.

4. Install stud nut and torque to 160 lbf-ft (220

Nm). Align nut with cotter pin slot (tighten)

and install a new cotter pin.

5. Torque mounting clamp bolt nut to 40-60 lbf-

ft (55-80 Nm), then test the adjustment.

Front wheels should turn from right to left

extremities without noticeable binding at

drag link ends.

3.7 BELL CRANK AND IDLER ARM

Bell crank and idler arm are equipped with one

lubrication fitting and should be lubricated as

directed in paragraph "3.11 Lubrication Fittings"

of this Section.

3.7.1 Bell Crank and Idler Arm Removal

NOTE

Use a piece of wire to anchor loosen end of

relay rod and tie rod in order to prevent

placing an excessive load on opposite socket

end.

Loading...

Loading...