Section 16: SUSPENSION

PA1562

15

Bell crank: Disconnect drag link, tie rod and

relay rod from bell crank by removing cotter

pins, stud nuts and washers from ball studs.

Separate socket assemblies from the bell crank.

Idler arm: Remove cotter pins, nuts and

washers from ball studs connecting relay rod

and tie rod to idler arm. Separate socket

assemblies from idler arm.

Remove nuts and washers from bolt attaching

bell crank or idler arm mounting bracket to

vehicle understructure. Remove bell crank or

idler arm mounting bracket.

3.7.2 Bell crank or Idler Arm Ball Joint

Disassembly

1. Remove adjacent link assemblies from bell

crank or idler arm as previously described.

2. Remove the cap (Fig.21).

3. Remove the cotter pin, nut and tongue

washer. Remove bearings, grease seal,

bearing bushing and the bell crank or idler

arm from its mounting bracket stud (Fig. 21).

3.7.3 Bell Crank or Idler Arm Ball Joint

Reassembly

NOTE

For bearing installation use tool Prévost #

110684.

1. Install bearing bushing on bell crank or idler

arm mounting bracket stud.

2. Install bearing and grease seal in bell crank

or idler arm eye (Fig. 21).

NOTE

Install grease seal according to figure 21.

Grease must be able to exit the bell crank or

idler arm mechanism. For grease seal

installation use tool Prévost # 110683.

3. Install bell crank or idler arm on its mounting

bracket stud (Fig. 21).

4. Install bearing and nut.

NOTE

Apply grease on bearing before installation.

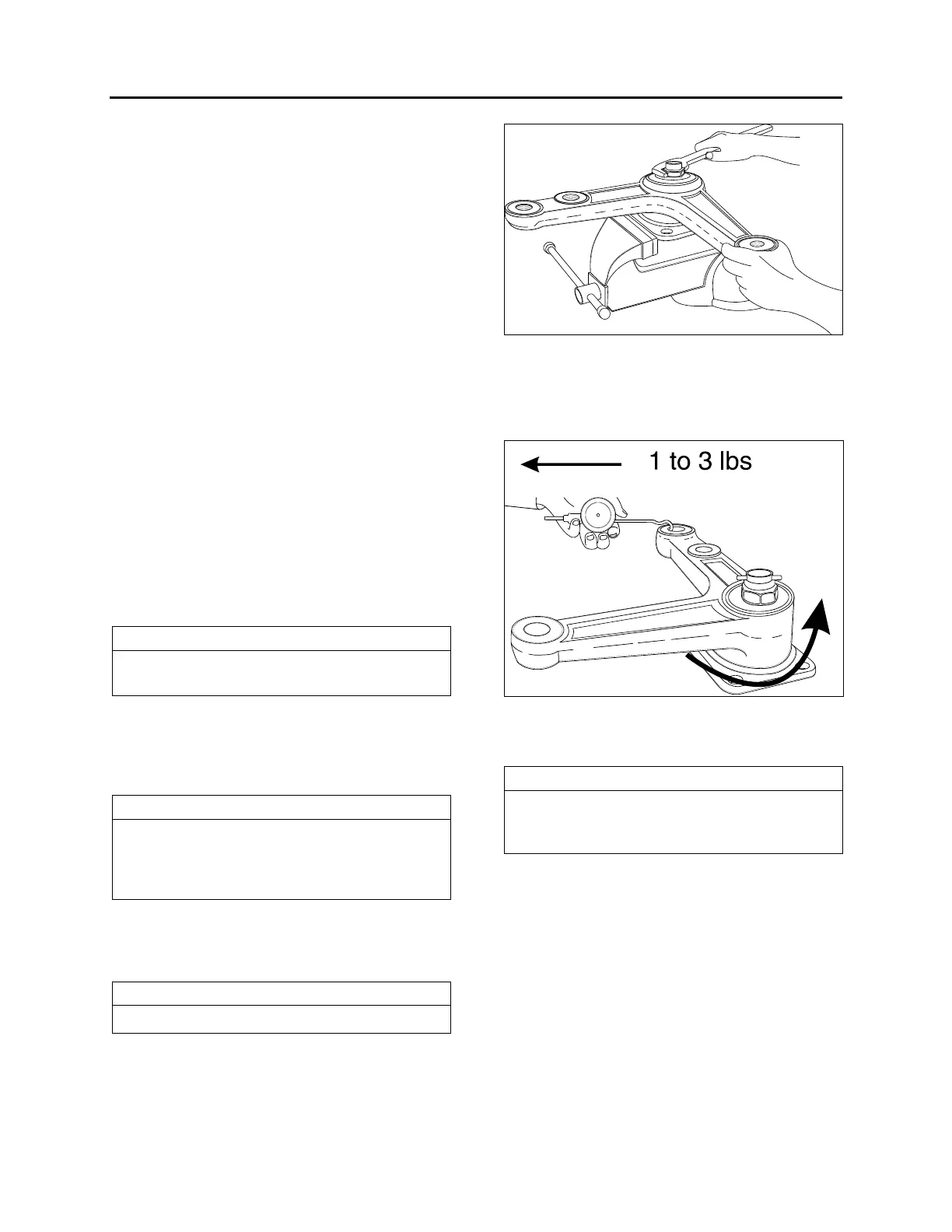

5. Firmly tighten nut (Fig. 19).

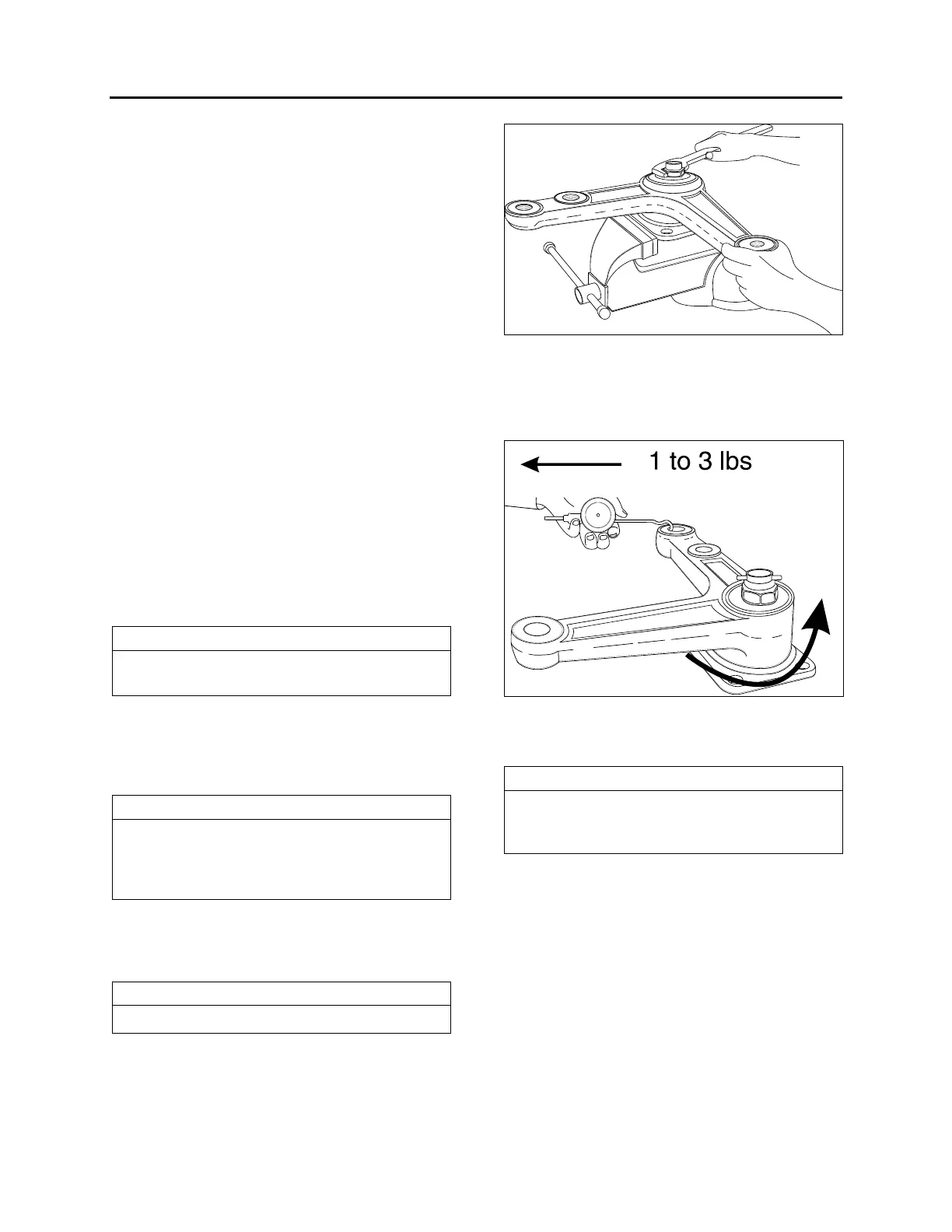

6. Unscrew nut until bell crank or idler arm

starts to turn by the application of 1 to 3

pounds load (Fig. 20).

FIGURE 19: BELL CRANK 16044

7. Check for loose bearings by applying an up

and down load on bell crank or idler lever

(Fig. 20). The lever is not supposed to move

in the vertical axis direction.

FIGURE 20: BELL CRANK 16045

8. Align nut with cotter pin slot (tighten) and

install a new cotter pin.

NOTE

Bend cotter pin around the nut (Fig. 21). Do

not bend the cotter pin in the direction of the

cap, because it may interfere with the cap.

9. Install the cap.

10. Bell crank: Install drag link, tie rod and

relay rod as directed herein under each

specific subject.

11. Idler arm: Install tie rod and relay rod as

directed herein under each specific subject.

12. Adjust turning angle as previously directed

under paragraph "Turning Angle" and

check front end alignment as specified in

paragraph "3.16. Front End Alignment" of

this section.

Loading...

Loading...