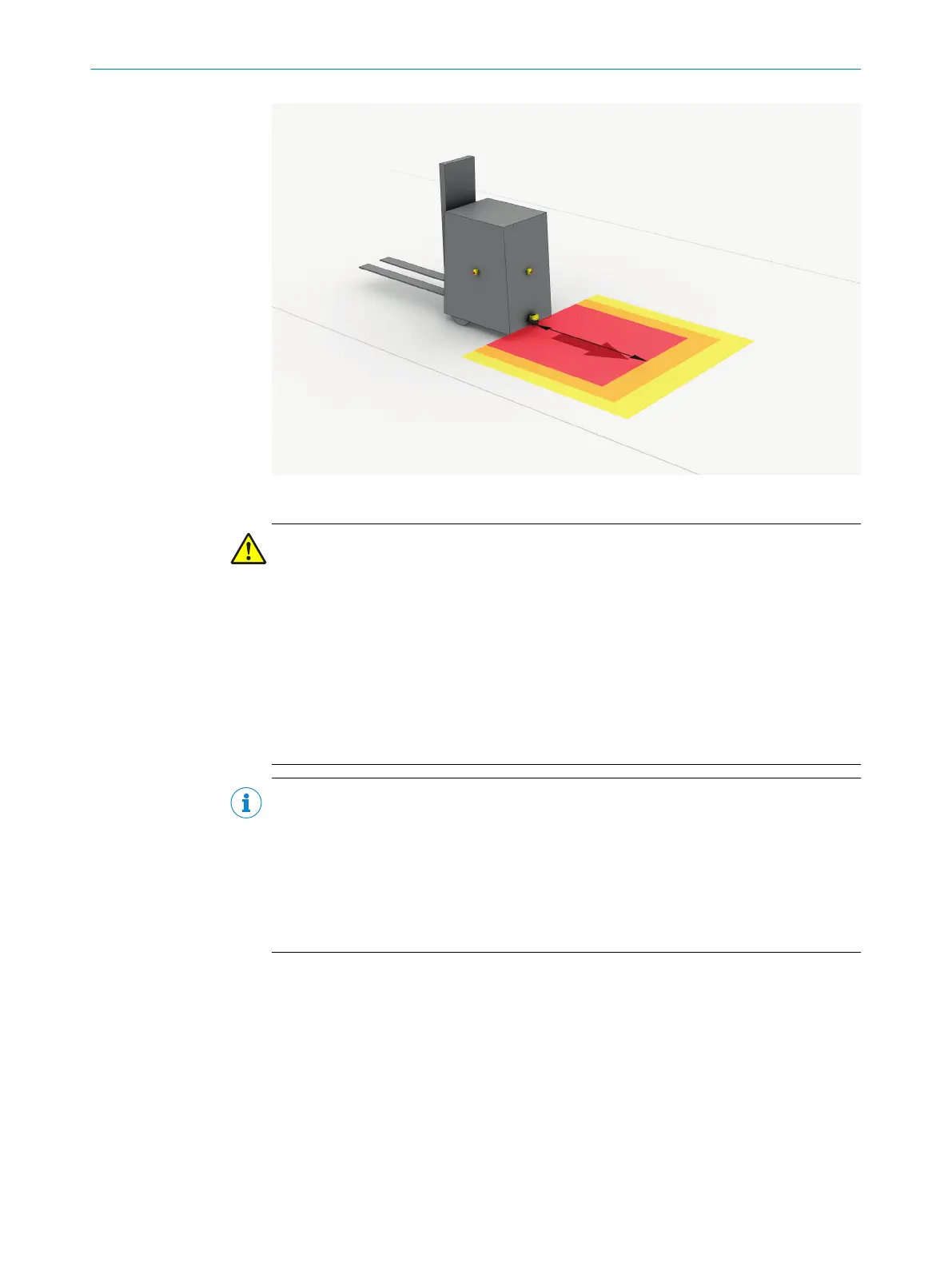

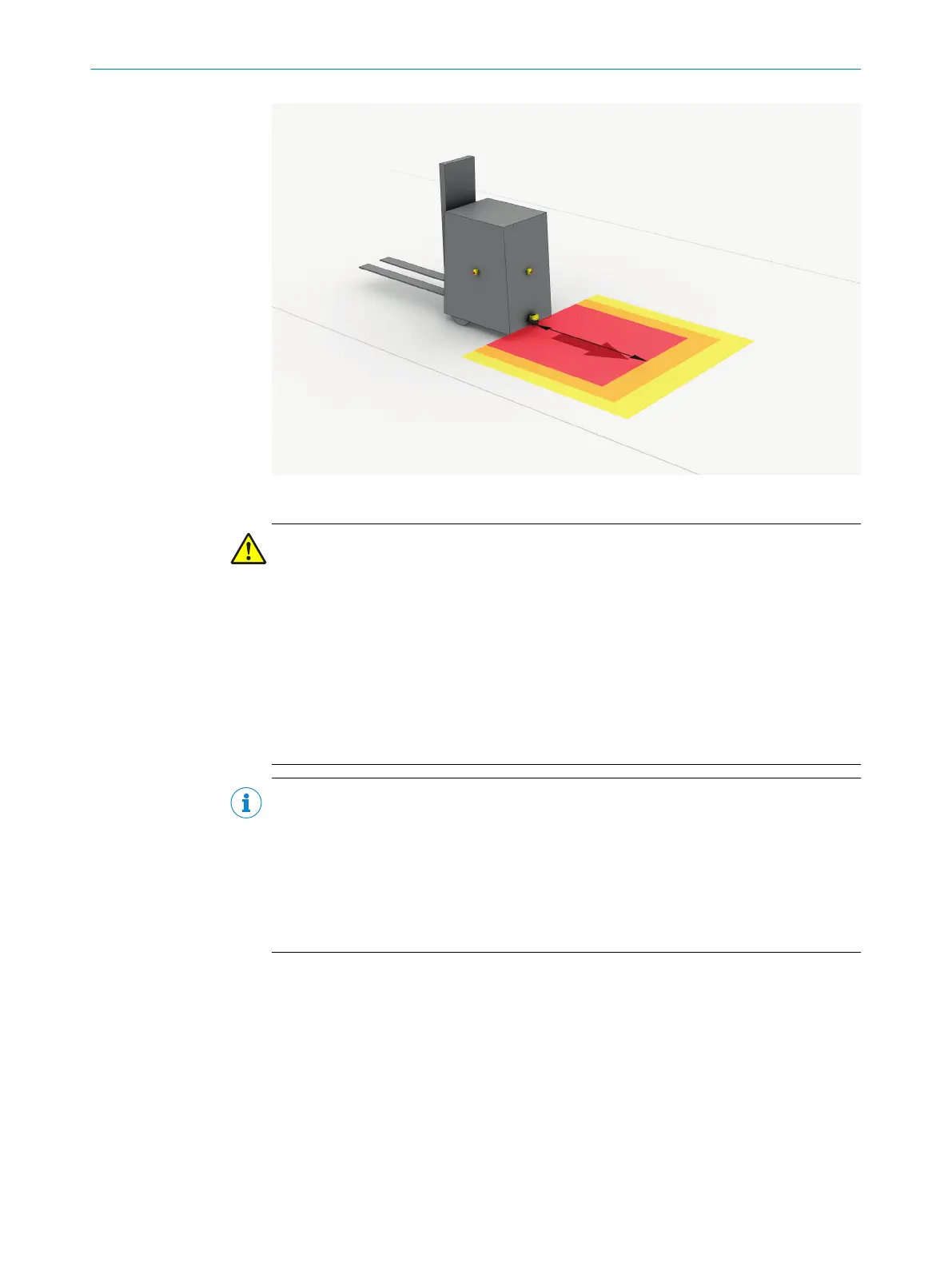

Figure 33: Mobile application in horizontal operation for hazardous area protection

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

1. Calculate the minimum dimensions required for the protective field taking into

account the supplements described in the following text along with the specific

requirements imposed by your application.

2. Take this calculation and the specifications in these instructions into account

when mounting the safety laser scanner.

3. Take this calculation and the specifications in these instructions into account

when configuring the safety laser scanner.

NOTE

•

In a mobile applic

ation, a resolution of 70 mm (leg detection) is sufficient for

detecting people. By contrast with stationary hazardous point protection, this is

also true for a low mounting height, as the safety laser scanner moves together

with the vehicle.

•

In the following calculation examples, only the vehicle speed is taken into account,

not the speed of a walking person. This is based on the assumption that the per‐

son recognizes the danger and stands still.

4.3.9.1 Protective field length

The protective field must be designed so that it detects a person at a minimum dis‐

t

ance from the hazardous point. This distance is required to ensure that the vehicle

comes to a stop before it reaches a person or an object.

In mobile hazardous area protection, the minimum distance typically defines the pro‐

tective field length required. When calculating the protective field length, the impact of

turning must be considered separately.

If you define a number of monitoring cases with different protective fields, you must cal‐

culate the protective field size separately for each protective field used.

PROJECT PLANNING 4

8021913/15ZW/2019-11-14 | SICK O P E R A T I N G I N S T R U C T I O N S | microScan3 – EFI-pro

47

Subject to change without notice

Loading...

Loading...