9 Operation

9.1 Safety

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

b

Maintenance work, alignment work, fault diagnoses, and any changes to the inte‐

gration of the protective device in the machine must only be carried out by quali‐

fied personnel.

b

The effectiveness of the protective device must be checked following such work.

NOTE

T

his document does not provide instructions for operating the machine in which the

safety laser scanner is integrated.

9.2 Regular thorough check

The protective device must be checked regularly. The type and frequency of thorough

c

hecks is defined by the manufacturer and the operating entity of the machine, see

"Testing plan", page 59.

The regular thorough checks serve to investigate the effectiveness of the protective

device and detect any ineffectiveness due to modifications or external influences (such

as damage or tampering).

b

Carry out the thorough checks according to the instructions from the manufacturer

and the machine operator.

9.3 LEDs

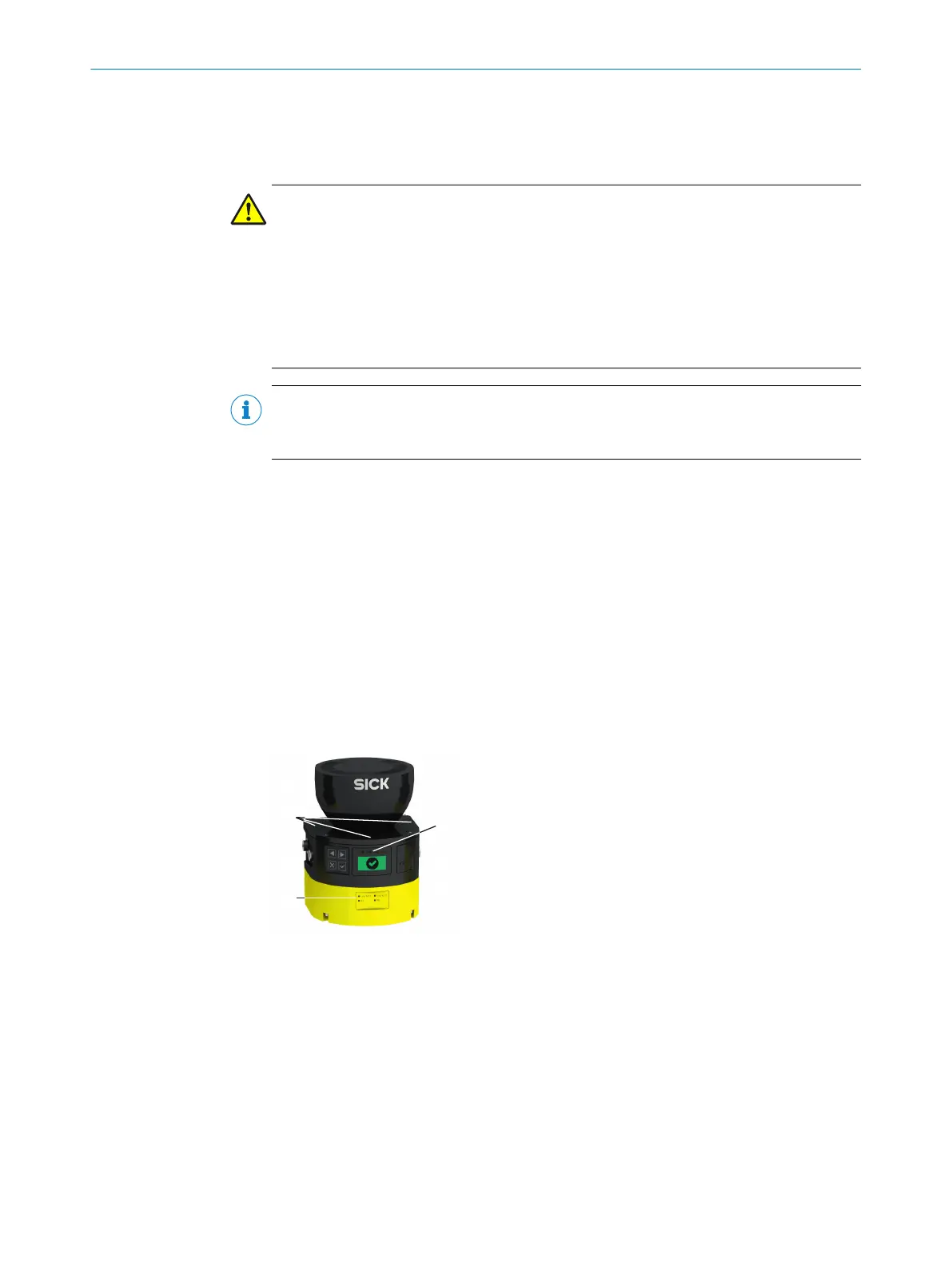

Figure 77: LEDs

1

Status LEDs

2

Additional LEDs for ON state and OFF state

3

Network LEDs

4 status light emitting diodes are located directly above the display.

OPERATION 9

8021913/15ZW/2019-11-14 | SICK O P E R A T I N G I N S T R U C T I O N S | microScan3 – EFI-pro

121

Subject to change without notice

Loading...

Loading...