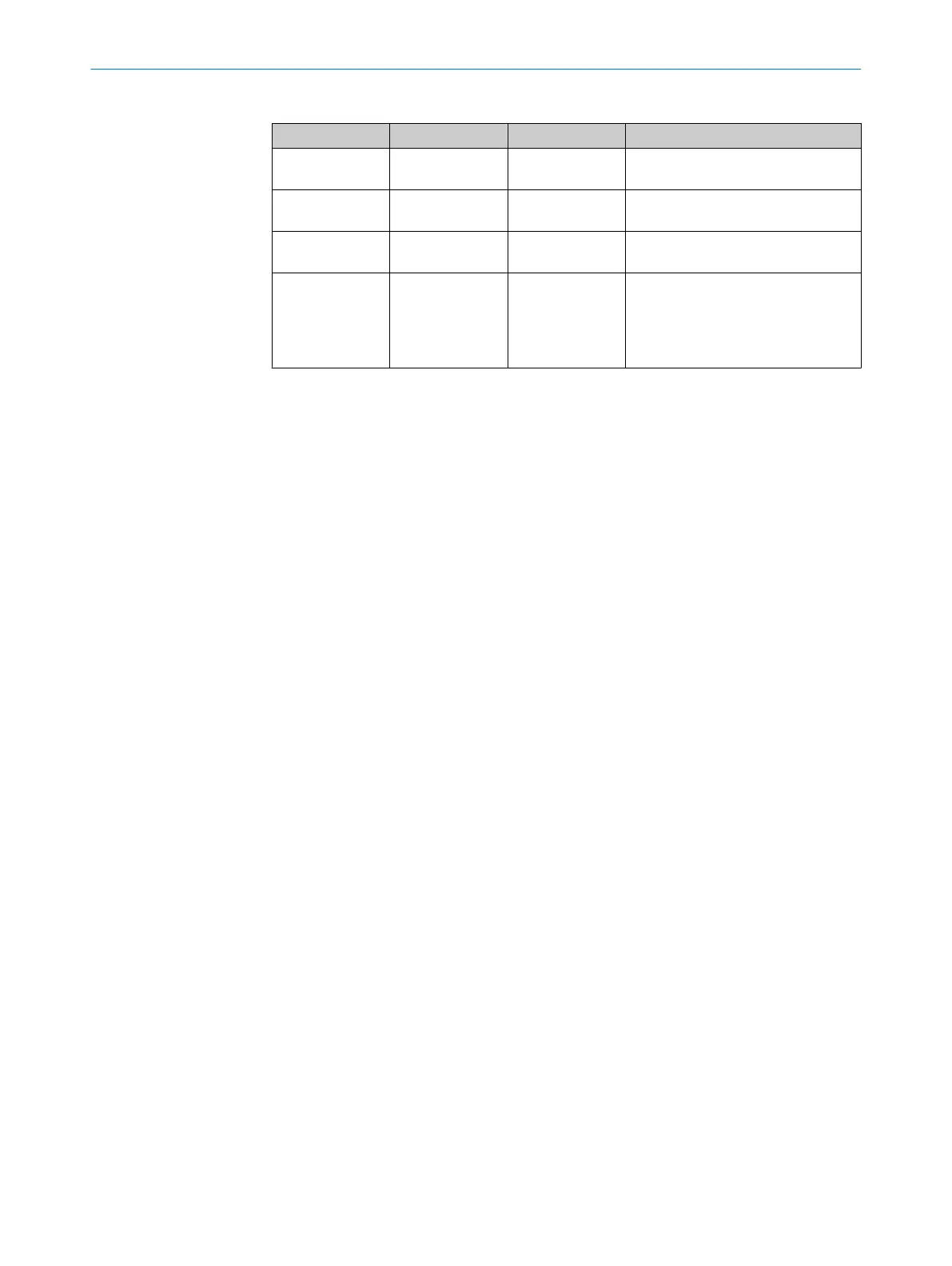

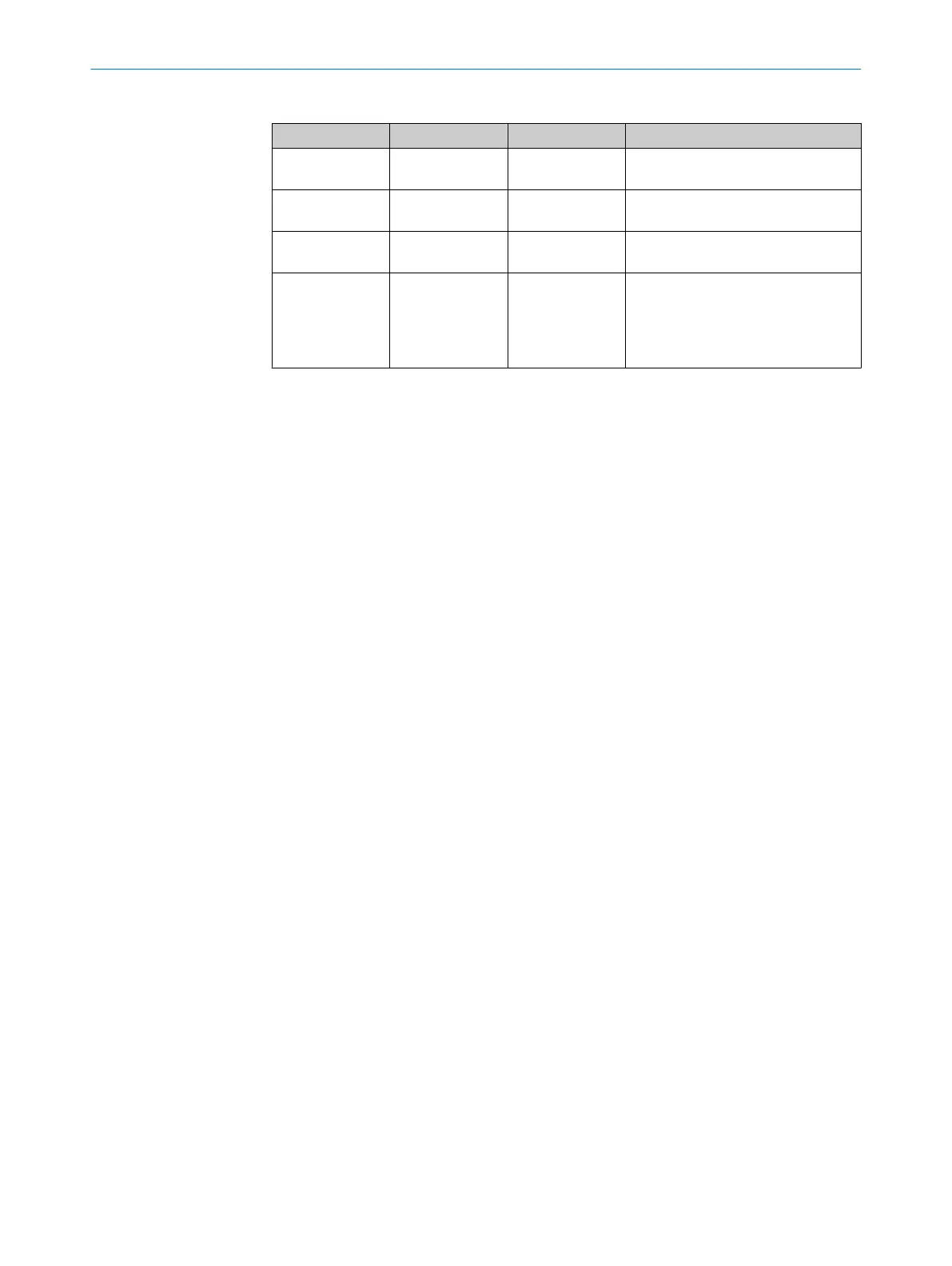

Table 2: Status LEDs

Number Function Color Meaning

1

OFF state Red Lights up red when at least one

s

afety output is in the OFF state.

2

ON state Green Lights up green when at least one

safety output is in the ON state.

3

Warning field Yellow Shines yellow if at least one warning

field is interrupted.

4

Restart interlock Yellow Setup with reset: Flashes if the

r

estart interlock has been triggered.

Configuration with automated restart

after a time: Lights up while the con‐

figured time to restart expires.

The OFF state and ON state light emitting diodes can be found in multiple locations on

t

he safety laser scanner. 3 additional sets are arranged in pairs on the base of the

optics cover. So the light emitting diodes can also be seen in many cases when it is not

possible to see the display, e.g. due to the mounting situation or because it is hidden

from the operator’s position.

The device has different light emitting diodes for every network interface. These net‐

work light emitting diodes are located below the display.

More information about the meaning of the light emitting diodes see "Diagnostic LEDs",

page 135.

Depending on the configuration, the display shows current information about the safety

laser scanner’s status, see "Buttons and display", page 122.

3.2.4 Connections

•

1 x male connec

tor, M12, A-coding for voltage supply

•

2 × female connector, M12, D-coding for Ethernet (EFI-pro, data output, configura‐

tion, and diagnostics)

•

1 × female connector, USB 2.0 Mini-B for configuration and diagnosis

2)

3.2.5 System plug

A system plug is required to operate the safety laser scanner.

T

he metal plate with the connections is the system plug (see figure 4, page 15). The

system plug can either be mounted on the rear side or the underside.

The safety laser scanner’s internal configuration memory is integrated in the system

plug. The system plug and all connecting cables can remain at the installation site

when the safety laser scanner is replaced. The system plug is detached from the defec‐

tive safety laser scanner and connected to the new safety laser scanner. The new

safety laser scanner reads the configuration from the configuration memory when

switching on.

3.2.6 Field types

During operation, the safety laser scanner uses its laser beams continuously to check

whe

ther people or objects are present in one or more areas. The areas to be checked

are called fields. A distinction is made between the following field types, depending on

how the safety laser scanner is used:

•

Protective field

•

Reference contour field

2)

T

he USB connection may only be used temporarily and only for configuration and diagnostics.

PRODUCT DESCRIPTION 3

8021913/15ZW/2019-11-14 | SICK O P E R A T I N G I N S T R U C T I O N S | microScan3 – EFI-pro

17

Subject to change without notice

Loading...

Loading...