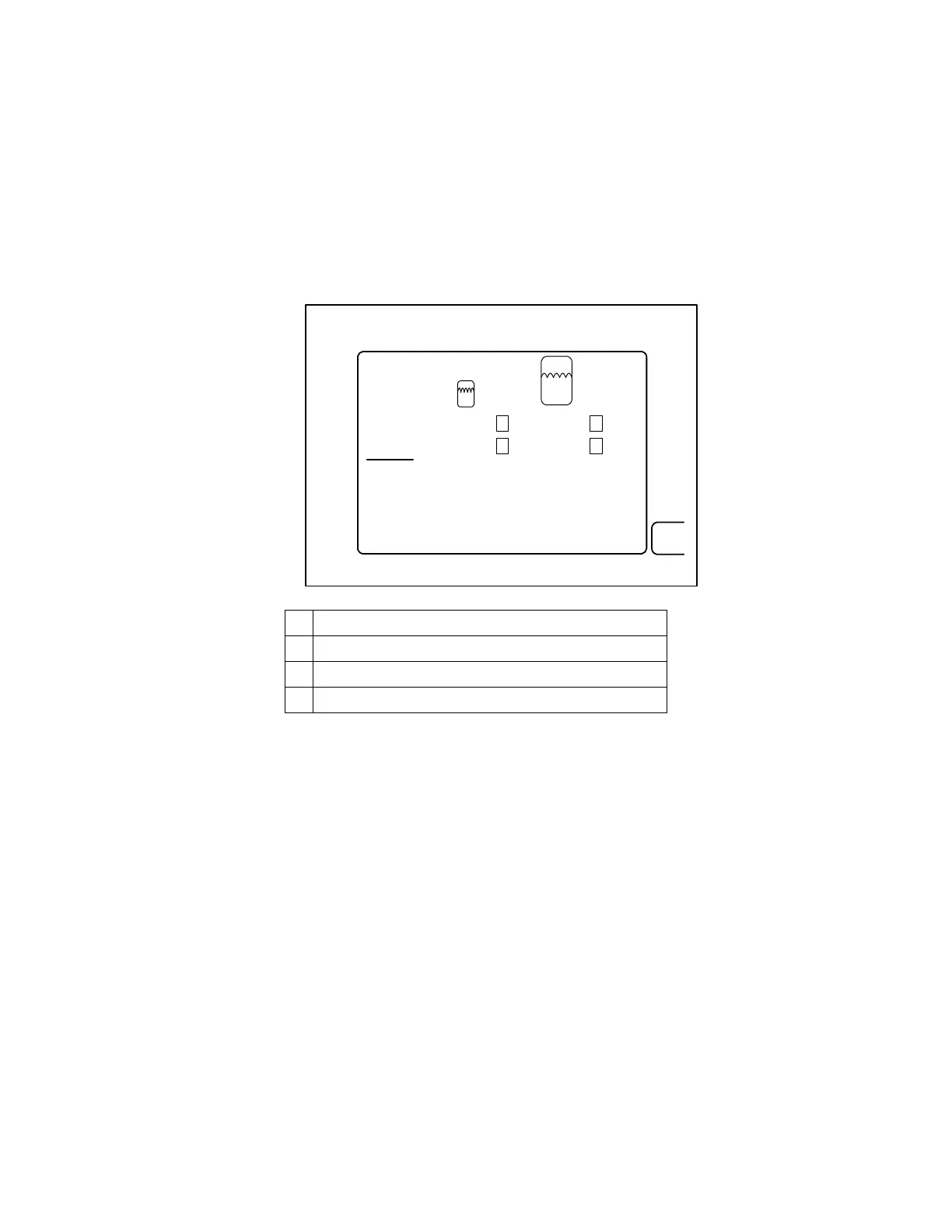

Once a response comes back, that value is displayed in the level sensor data

screen. The value will be a hexadecimal figure representing the physical location of

each magnet. (See Figure 2) The first value will be received from the small tank’s float

sensor, since it is the closest to the top of the transducer rod. Next the signal from the

small canister reference magnet will be received, followed by the signal from the large

canister’s float sensor. Finally, the signal from the large tank’s reference magnet will be

received. Under normal operation the values will be placed as shown in figure 2.

ESC

FLOAT

LEVEL SENSOR DATA

REF

1F341

192B8

06089DIFF

VOLUME 00445

APP

35D40

3CF40

07200

01071

B

C

D

E

B Response From Small Tank Float Sensor

C Response From Small Tank Reference Magnet

D Response From Large Tank Float Sensor

E Response From Large Tank Reference Magnet

Figure 2. Response Time Values For Level Sensor

Each magnet has a number range that it should fall between. (Especially the

reference magnets since they do not move) The software does not compare the actual

returned values to make sure they are within an expected returned value range. It

simply takes the first response and assumes the value is the response for the small

canister’s float sensor [B]. Likewise, the second response is automatically assumed to

be the response for the small canister’s reference magnet [C]. Therefore, if only one

magnet has failed, the remaining three responses will be entered as if they were the

expected first three. The data for the fourth response will be missing. (It was placed in

the 3

rd

slot) Consequently, the large tank’s reference magnet’s slot will display all zeros.

Figure 3 illustrates the expected value range for all four magnets, while Figure 4 is an

example of what the level sensor data screen will display when a magnet has failed.

6-36

Loading...

Loading...