HYDRAULICS

4181383 First Edition 6-21

6

Field Test Procedures

Lift Cylinder Leakage Test

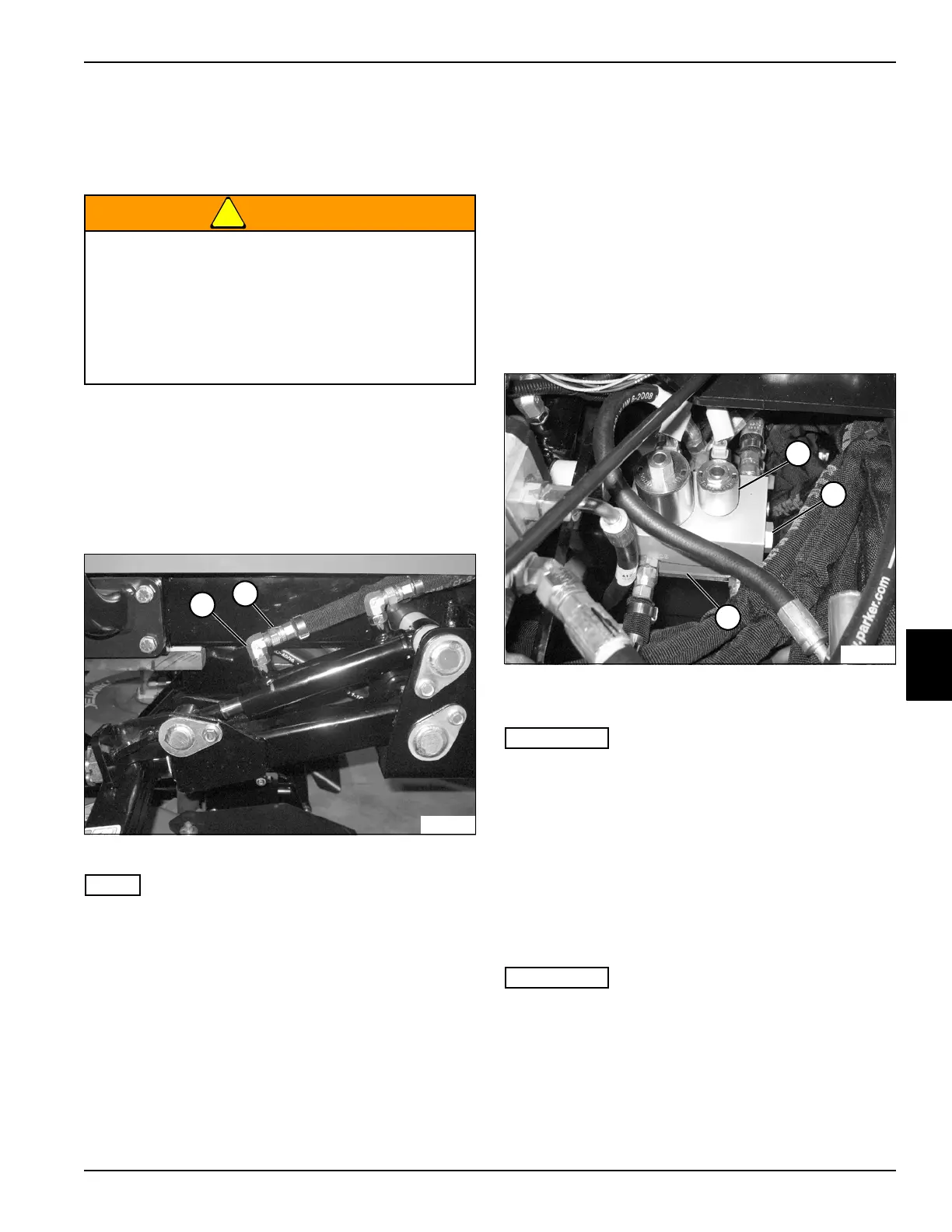

See Figures 6-13 and 6-14.

!

WARNING

1. Start engine. Operate hydraulic system until oil

temperature is at 120—150°F (49—65°C).

2. Raise cutting units.

3. Park the mower safely. (See “Park Mower Safely” on

page 1-5.)

4. Support all cutting unit lift arms.

.

Figure 6-13

NOTE

Figure 6-12 shows left rear lift arm cylinder. Procedure is

similar for right rear and front lift cylinders.

5. Disconnect hose (2) from lift cylinder rod end fitting

(1).

6. Install plug in hose (2).

7. Install cap on lift cylinder fitting (1).

8. Remove support from cutting unit lift arm being

tested.

After 15 minutes, does cutting unit drift down?

YES Cylinder is bypassing oil. Replace lift

cylinder. (See “Lift Cylinders” on page 6-49.)

NO Repeat the test for all of the lift cylinders. If

all cylinders pass test, the problem may be in

the lift valve. Proceed to step 9.

9. Support all cutting unit lift arms.

10. Connect hose (2) to lift cylinder fitting (1).

11. Start the engine and lower cutting units.

12. Stop the engine.

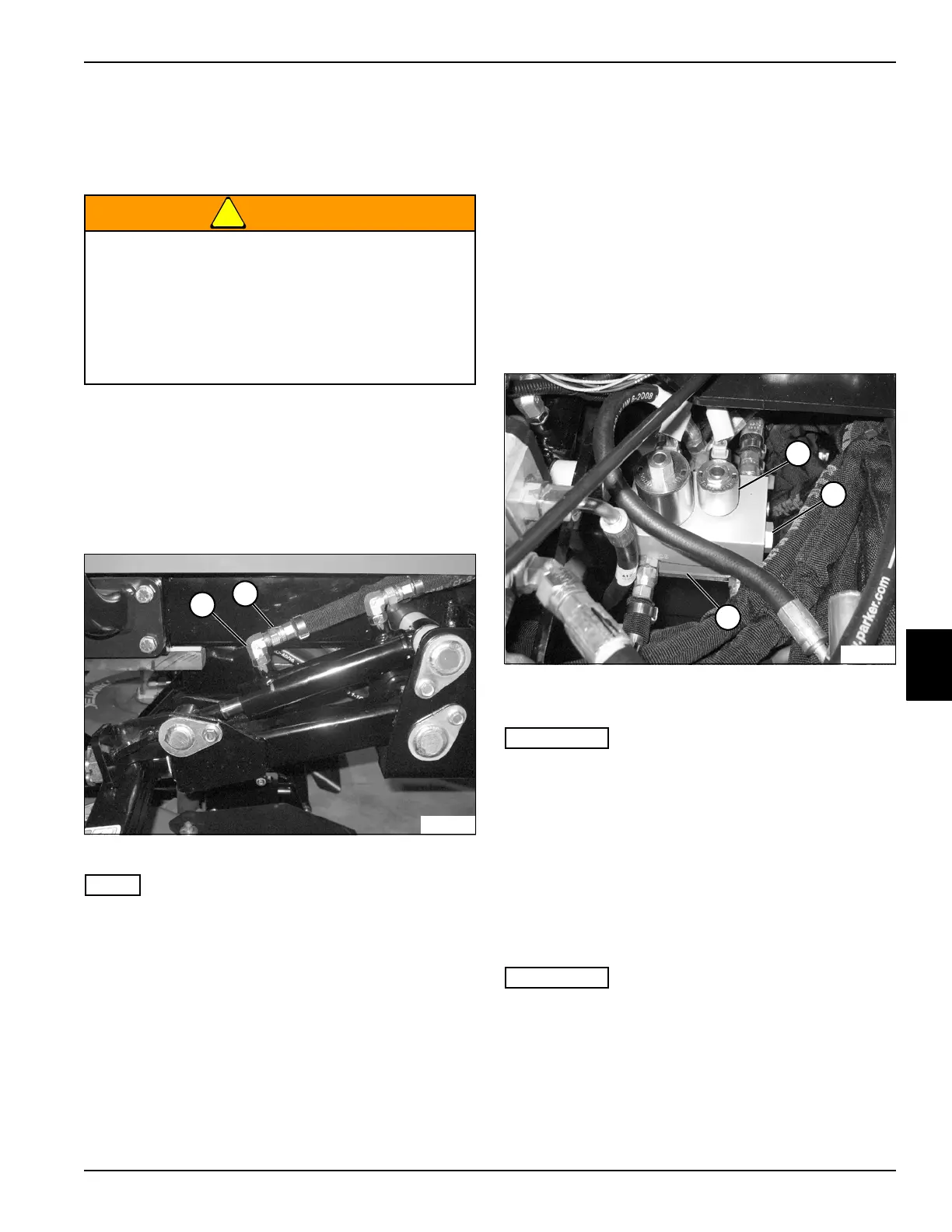

Figure 6-14

13. Remove the center floorboard.

IMPORTANT

Cutting units must be lowered to the ground.

14. Remove check valve (4) from the lift valve body (5).

15. Clean and inspect check valve for damage. Replace

as necessary.

16. Start the engine and raise the cutting units.

17. Stop the engine.

18. If lift cylinders continue to drift down, start the engine

and lower the cutting units.

19. Stop the engine.

IMPORTANT

Cutting units must be lowered to the ground.

20. Remove lower/proportional solenoid valve (3) from lift

valve body (5).

21. Clean and inspect lower/proportional solenoid valve

for damage. Replace as necessary. (See “Solenoid

Test” on page 4-63.)

The hydraulic system is under pressure, and the

oil will be hot.

• Always relieve pressure in the hydraulic

system before performing service.

• Failure to follow appropriate safety

precautions may result in death or serious

injury.

TN1406

1

2

TN1407

3

5

4

Loading...

Loading...