714

Model Code Page

42. Gearbox

15. 5. 1996

6000--8750 423 10

8. 11. 1990

2452

0,025 ---0,075

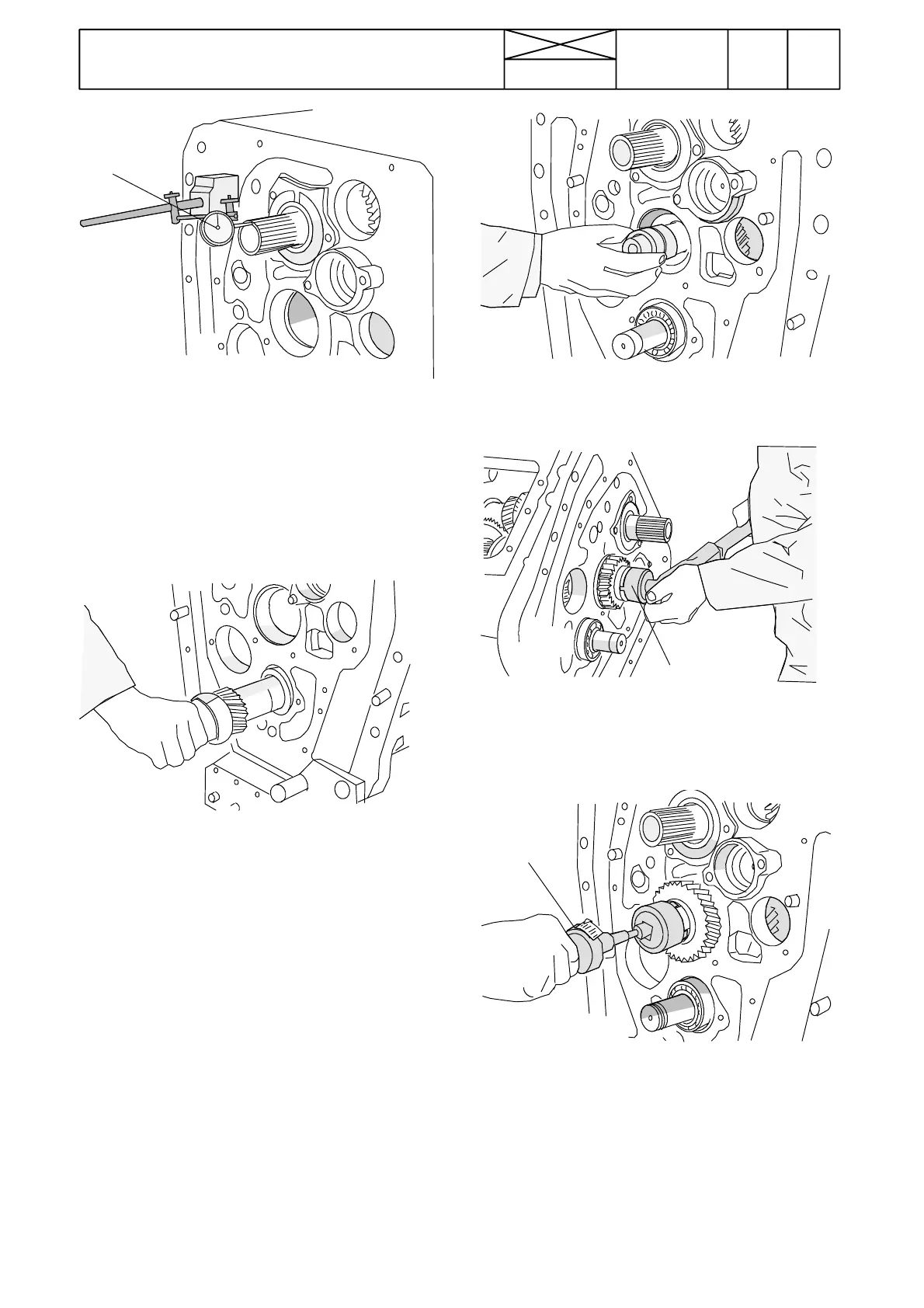

12. Measure the input shaft end float. It should be

0,025 ---0,075 mm. Increase or decrease the shim thickness

as necessary.

13. In the same way adjust the end float of the layshaft. End

float should be 0, 025 ---0,075 mm.

Note! Turn the layshaft 20---30 revolutions in order to bed in

the bearings before measuring. Fit the layshaft front end

cover in the right way (the thin side up).

2

6

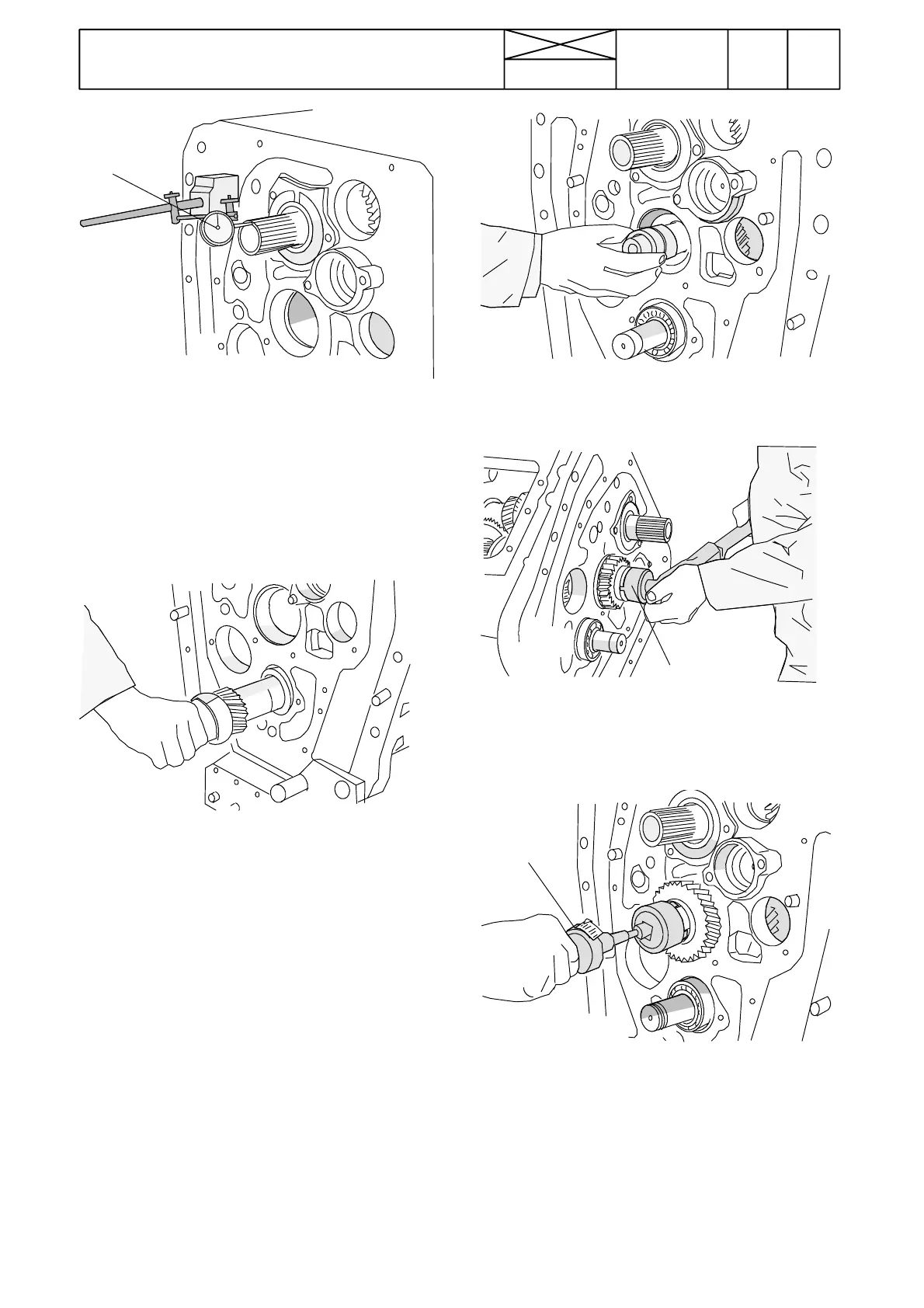

14. Fit the transmission shaft into the gearbox through the

front bearing hole. Note! Theremustbethewidegearcirclip,

the spacer and needle bearings on the shaft.

15. Fit onto the shaft first the broad gear wheel, spacer ring,

circlip and the narrow gear wheel.

16.Fitthecirclipsintotheirplaces.Tapattheshaftfrontend

until the shaft is in place.

Note! It may be easier (lack of space)to fit firstthe bevel pinion

shaft and after that the transmission shaft.

17. Fit the bevel pinion shaft rear bearing onto the shaft if

removed (warm up the bearing before fitting).

18. Fit the pinion shaft gears and synchro nizing units into the

gearbox as follows:

--- fit first the foremost gear and the rearmost gear

--- then fit other parts using the pinion shaft as a support. Cou-

plers for AVO and LL are kept in place by hand and the shaft

is pushed through them.

2454

--- Through the front bearing hole are fitted the bushing for the

foremost gear, end plate and the earlier spacer rings (2 pcs).

2455

ETV 892 230

19. Fit the front bearing outer race into its location. Fit the front

bearing with sleeve ETV 892370, fit the 4WD output gear and

tighten the nut to a torque of 270 Nm (ETV 892230).

2

56

1,7 ---2,3 Nm

20. Measure the rolling resist ance of the pinion shaft bearings

with a torsion meter. Correct value is 1,7---2,3 Nm.Increase

or decrease the spacer ring thickness as necessary.

Note! 13 different thickness of spacer rings are available

(thickness between 5,03---5,93 mm). Make sure that the shaft

can rotate freely. Rotate the shaft 20---30 revolutions before

measurement.

21. After adjustment, tighten the shaft nut to a correct torque

and lock it with locking washer tabs.

Loading...

Loading...