239

Model Code Page

51. Brake system

1. 9. 2002

6000--8950 511 1

8. 11. 1990

Reconditioning brakes (Op. no. 511)

1. Service brakes

A. Changing brake discs

Note! There are oil grooves on the friction surface of the

brake discs. On new discs the grooves are 0,3 mm deep. If

thegroovesarewornaway,thebrakingefficiencywillbe

impaired and the discs should be replaced.

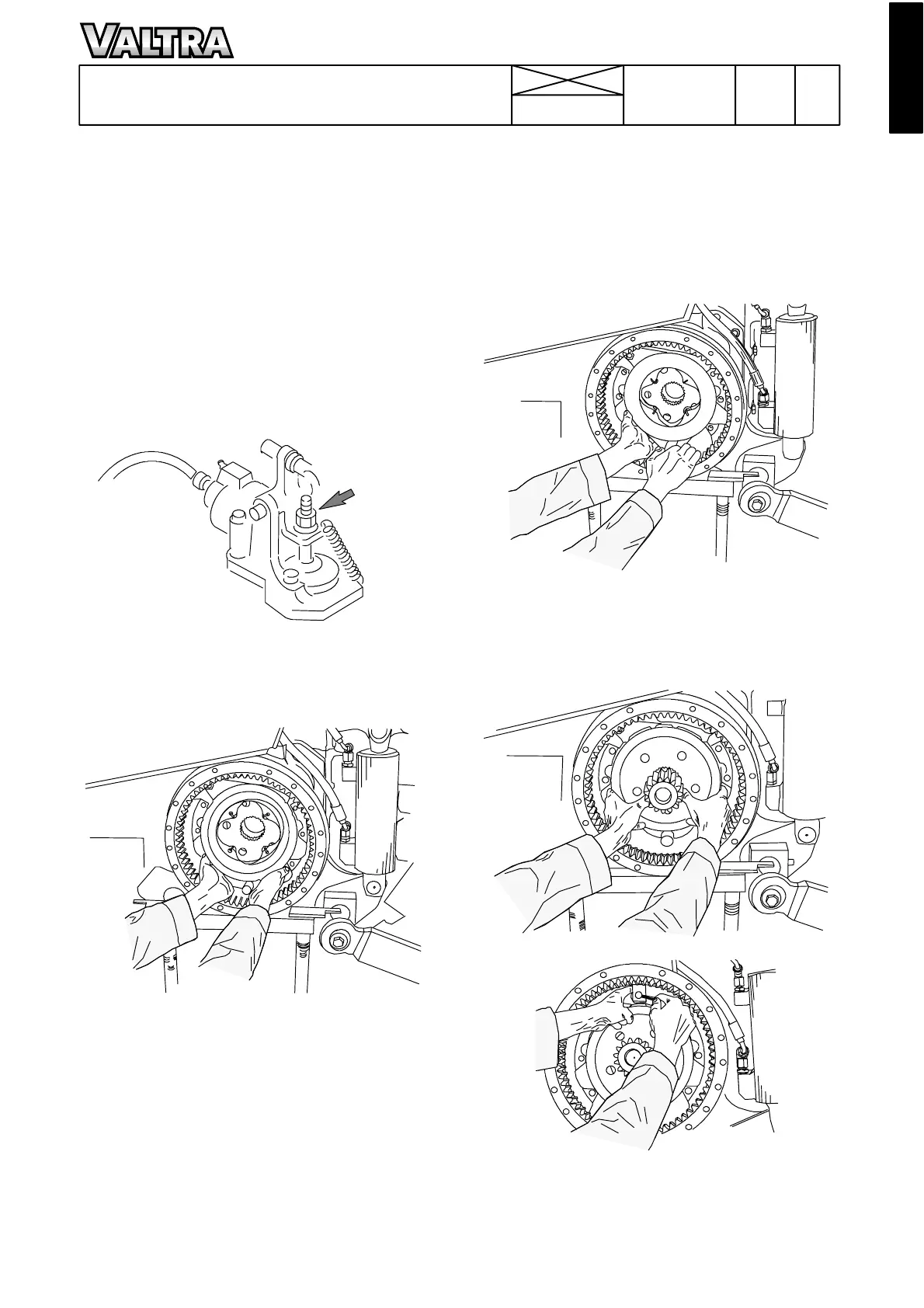

1. Remove the final drives (see Op. 451 1A).

2. Pull out the inner drive shaft. Remove the o uter support

plateinfrontofthediscs.

3.Removetheouterbrakediscs.

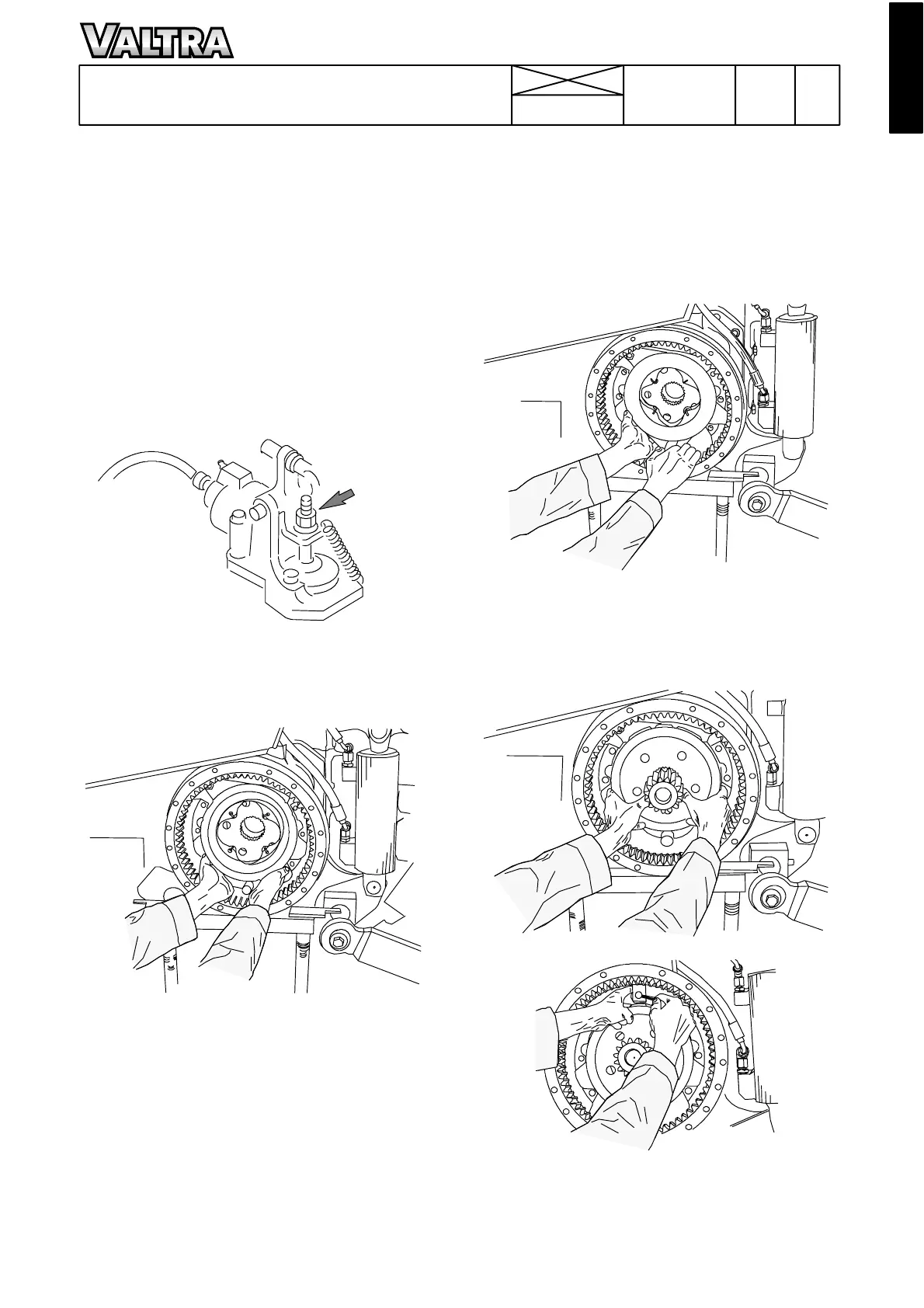

4. Slacken the adjusting nut (see arrow) until the brake

mechanism is loose.

5. Take out the cotter pin and the link pin at the lower end o f

the stay. Pull the stay up until it is free from the application

plate.

5a. Final drives 300, 450, 650: Remove the application

plates by simultaneously pulling out the anchor bolt, fitted

under the plate, and loosening the lower end of the plate

from its position.

Note! The removal of the applic ation plates is easier if the

outermost circl ip is removed from the anchor bolt.

5b. 8350---8950Hi with final drives 700 has not an anchor

bolt . Pull the application rings out of the housing.

6. Remove the inner brake discs.

7. Chec k the friction surfaces in t he brake housing and pol-

ishwithanemerycloth.

8a. Final drives 300, 450, 650: Push the anchor bolt in

through the hole in the brake housing, but do not press it

right home. Fit the inner brake discs on the anchor bolt.

Check t hat the discs remain located in front of the inner

circlip.

8b. In connection with final drives 700 there is not the an-

chor bolt. Place the inner brake discs and the intermediate

discs in position so that the lugs engage into the grooves

on the brake housing.

9. Final drives 300, 450, 650: Insert the application plate

into the housing with the upper edge first locating the lower

edge of the plate on the pulled ---out anchor bolt. Press the

bolt and the application plate into position. Fit the outer

circlipontheanchorbolt. Inconnectionwithfinaldrives

700, pass the application plate into place so that lugs on it

engage into the grooves in the housing.

11. Us ing the link pin connect the brake stay to the link

arms of the application plate and secure with the cotter pin.

Tighten the adjusting nut at the upper end of the stay.

Loading...

Loading...