ENGINE

M6060, M7060, WSM

1-M16

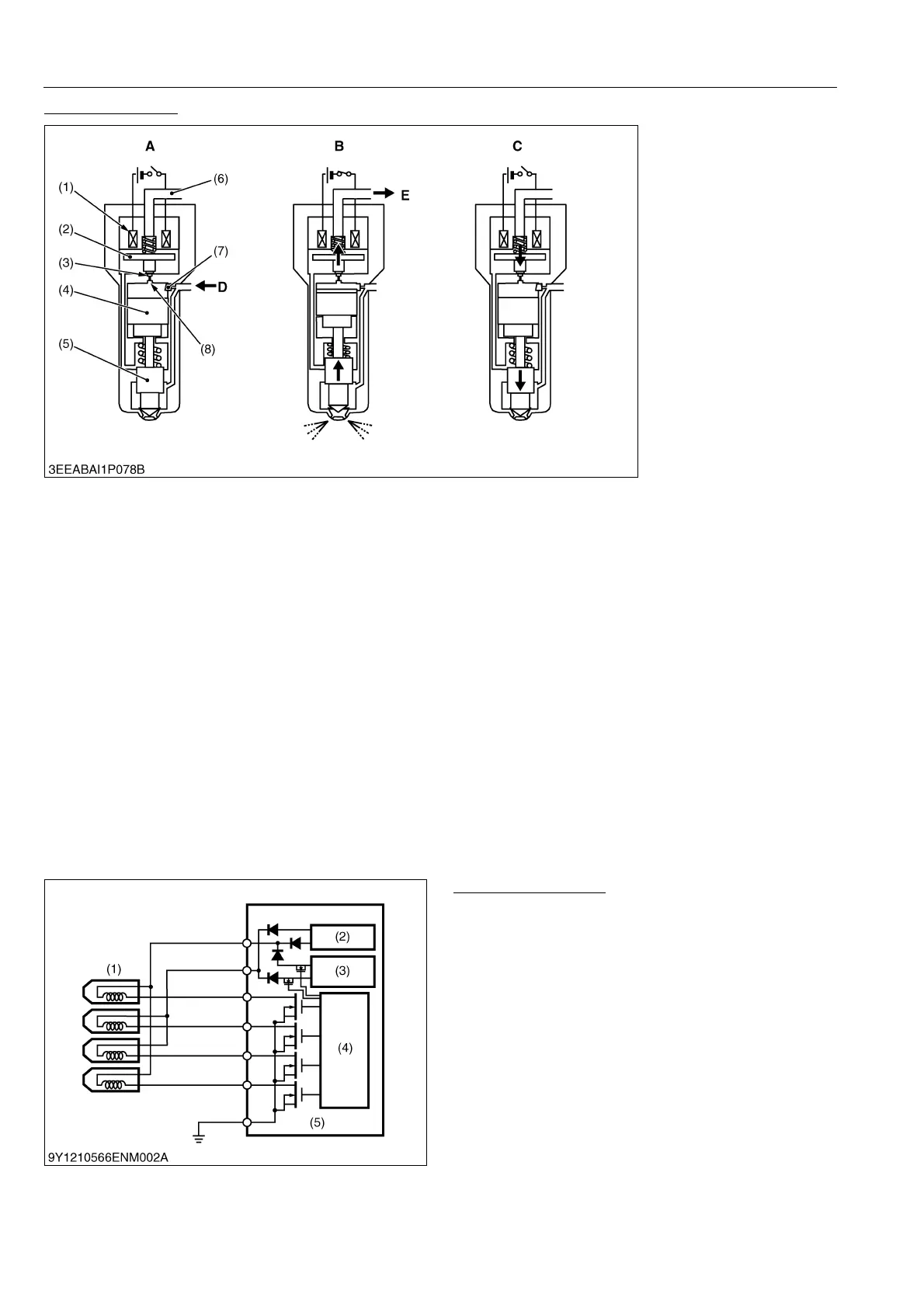

Injector Operation

The injector uses the signal output from the engine ECU to control the injection with the fuel pressure in the control

chamber.

The system for controlling the pressure of the control chamber works by energizing the solenoid, which opens the

passage of the chamber's discharge orifice and the fuel is injected due to the drop in pressure. When the current

stops, the pressure in the control chamber returns to what it was and injection ceases.

1) Injection Stop

With no current to the solenoid (1), the TWV (2) cuts off the discharge orifice (3) passage, so rail pressure is

applied to the control chamber (8) and the bottom of the needle valve (5). As the diameter of the command piston (4)

on the control chamber side is larger than the diameter of the bottom of the needle valve, it works to push the needle

valve down, which is compounded by the nozzle spring pushing it down, and the needle valve is closed.

2) Injection Start

When the solenoid (1) is energized, it draws the TWV (2) up, opening the passage of the discharge orifice (3),

returning fuel in the control chamber (8) to the fuel tank via the leak passage (6) and dropping the pressure.

The drop in the pressure of the control chamber causes the pressure applied to the bottom of the needle valve

(5) to become greater than the pressure on the control chamber side, and the needle valve compresses the nozzle

spring and starts injecting fuel.

3) Injection Finish

When current to the solenoid (1) stops, the TWV (2) lowers and the discharge orifice (3) passage is closed.

When the passage of the discharge orifice closes, the fuel pressure in the control chamber (8) recovers to the rail

pressure, so the needle valve (5) is pressed back via the command piston (4), stopping the injection.

9Y1210828ENM0025US0

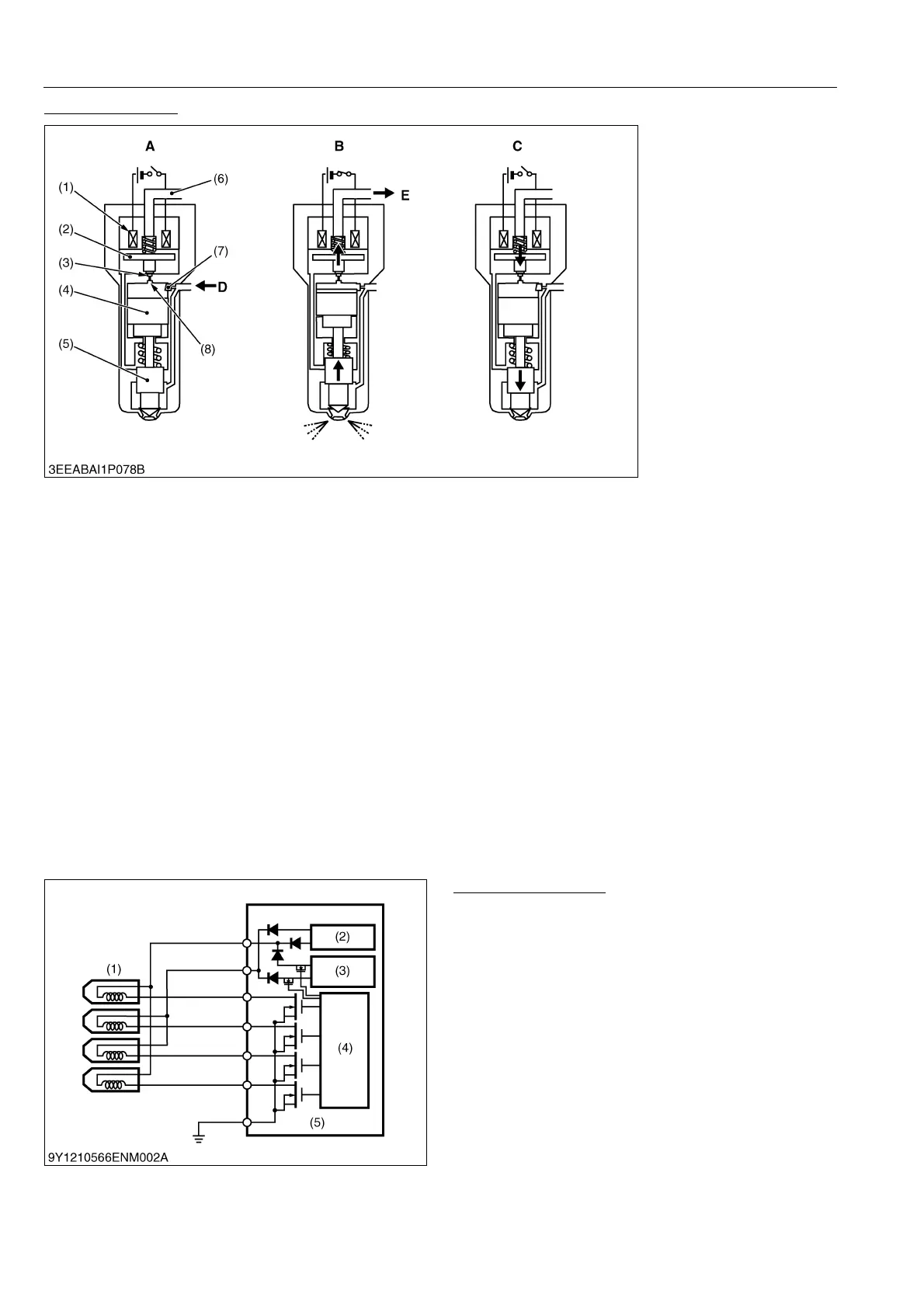

Injector Drive Circuit

To increase the responsiveness of the injector, the

voltage that drives the injector is raised to a high voltage,

accelerating the magnetization of the solenoid and

increasing the responsiveness of the TWV.

The battery voltage is raised to about 110 V by a

high-voltage generating circuit inside the ECU and that

voltage is supplied to the injector to actuate it.

9Y1210828ENM0026US0

(1) Solenoid

(2) TWV (Two-way Valve)

(3) Discharge Orifice

(4) Command Piston

(5) Needle Valve

(6) Leak Passage

(7) Intake Orifice

(8) Control Chamber

A: Injection Stop

B: Injection Start

C: Injection Finish

D: From Rail

E: To Fuel Tank

(1) Injector

(2) Rated Amperage Circuit

(3) High-voltage Generating

Circuit

(4) Control Circuit

(5) Engine ECU

Loading...

Loading...