ENGINE

M6060, M7060, WSM

1-S55

(Continued)

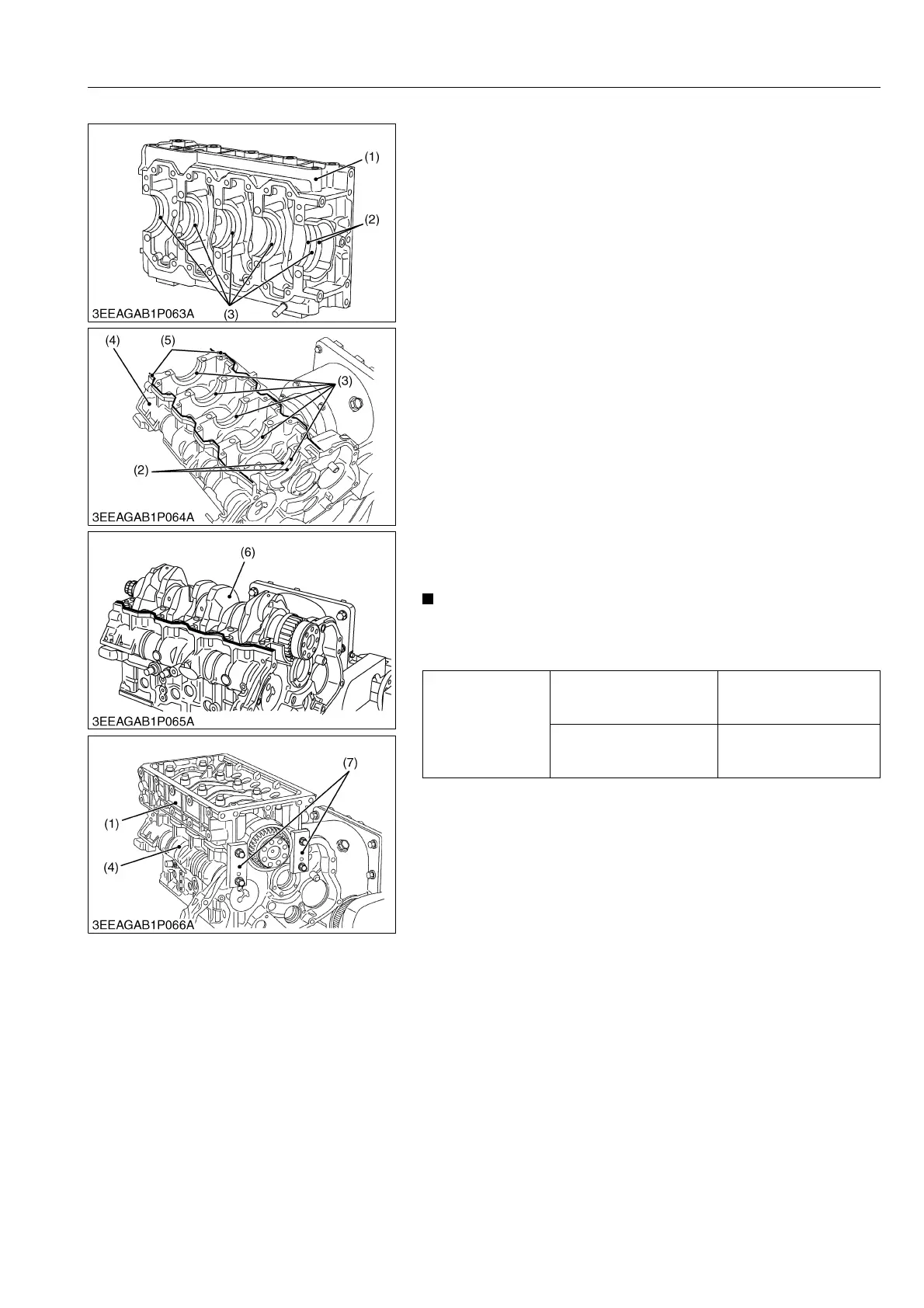

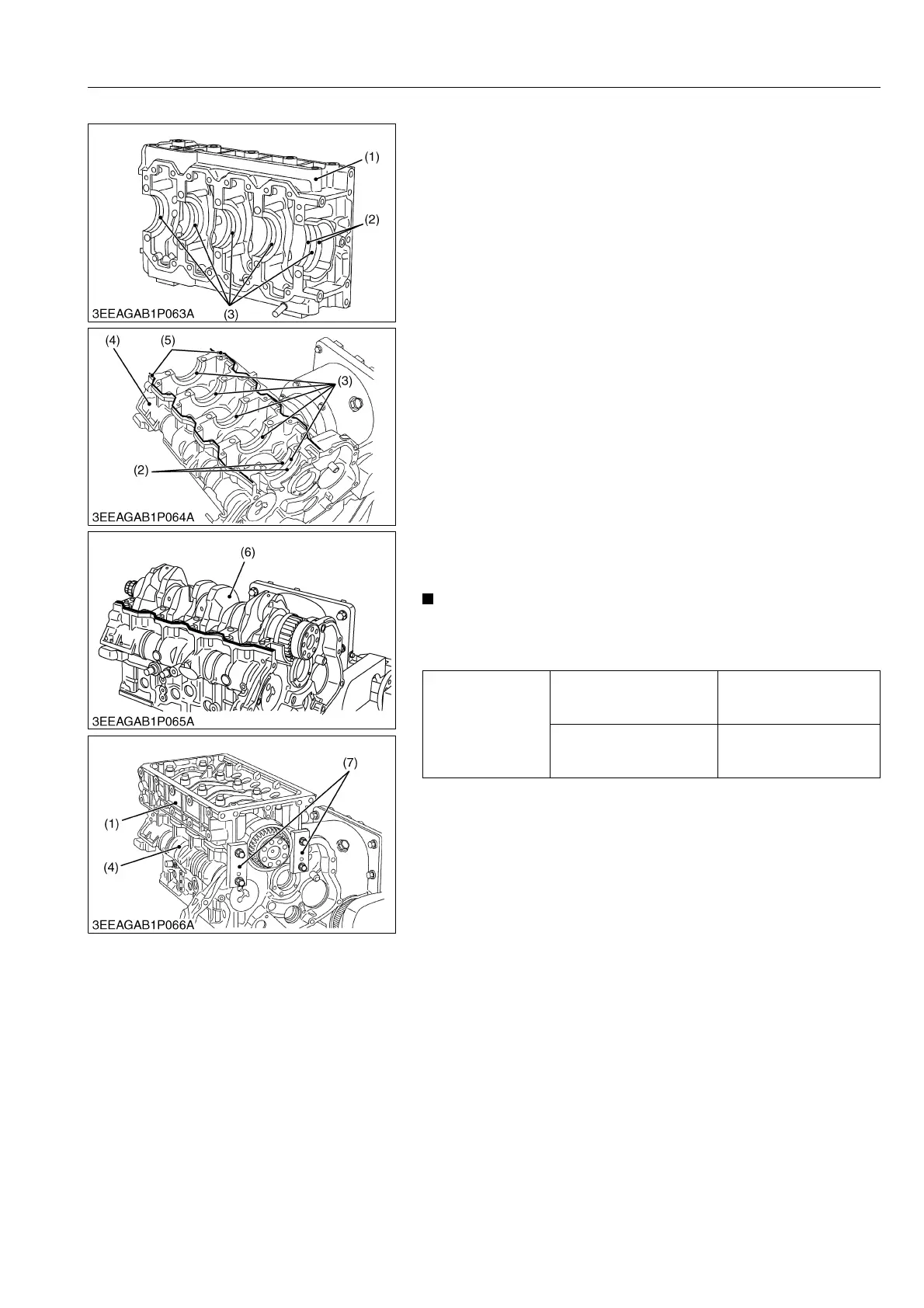

(When reassembling)

• Make sure the crankcase 1 (4) and 2 (1) are clean.

• Reassemble the crankshaft bearing (3) into crankcase 1 (4) and

2 (1).

• Reassemble the thrust bearing (2), with the oil groove facing

outside, into both flywheel housing edge journal side of the

crankcase 1 (4) and 2 (1).

• Apply oil to the thrust bearing and set the crankshaft (6).

• Apply liquid gasket (Three Bond 1217H or equivalent) (5) to the

crankcase 1 as shown in the figure.

• Make sure that the liquid gasket coating surface is free of water,

dust and oil in order to keep sealing effect.

• Carefully apply the adhesive evenly.

• Match the crankcase 1 (4) and 2 (1), referring to the flywheel

housing's contoured face.

• Tighten the crankcase 2 mounting screws (A to J) and the

crankcase 2 flange screws (K to Z) loosely after applying engine

oil.

• Tighten up the jig (7) to the specified torque same as the

flywheel housing screw. (See page G-59.) This helps to

minimize the level difference between the crankcase 1 (4) and

the crankcase 2 (1) (at the flywheel side). Possible gap must be

0.05 mm (0.002 in.) or smaller.

• Tighten the crankcase 2 mounting screw and the crankcase 2

flange screw in the order of A to Z. (Refer to previous page.)

• When mounting the adhesive-applied parts, be careful to fit

them to the mating parts.

• Assemble the adhesive-applied parts within ten minutes.

9Y1210828ENS0076US0

Tightening torque

Crankcase 2 mounting

screw (A to J)

138 to 147 N·m

14.0 to 15.0 kgf·m

102 to 108 lbf·ft

Crankcase 2 flange screw

(K to Z)

59 to 63 N·m

6.0 to 6.5 kgf·m

44 to 47 lbf·ft

(1) Crankcase 2

(2) Thrust Bearing

(3) Crankshaft Bearing

(4) Crankcase 1

(5) Liquid Gasket

(6) Crankshaft

(7) Jig

Loading...

Loading...