313

7-6 Application outlines

Under the circumstances of continuous output, the system whose effect ability will die down

with the change of the feedback value can do auto tune, such as temperature or pressure. It is

not suitable for flux or liquid level.

Under the condition of overshooting permission, the system will get the optimal PID

parameters from auto tuning.

Under the condition that overshoot not allowed, the PID parameters got from auto tune is up

to the target value, it means that different target value will produce different PID parameters

which are not the optimal parameters of the system and for reference only.

If the auto tune is not available, users can set the PID parameters according to practical

experience. Users need to modify the parameters when debugging. Below are some

experience values of the control system for your reference:

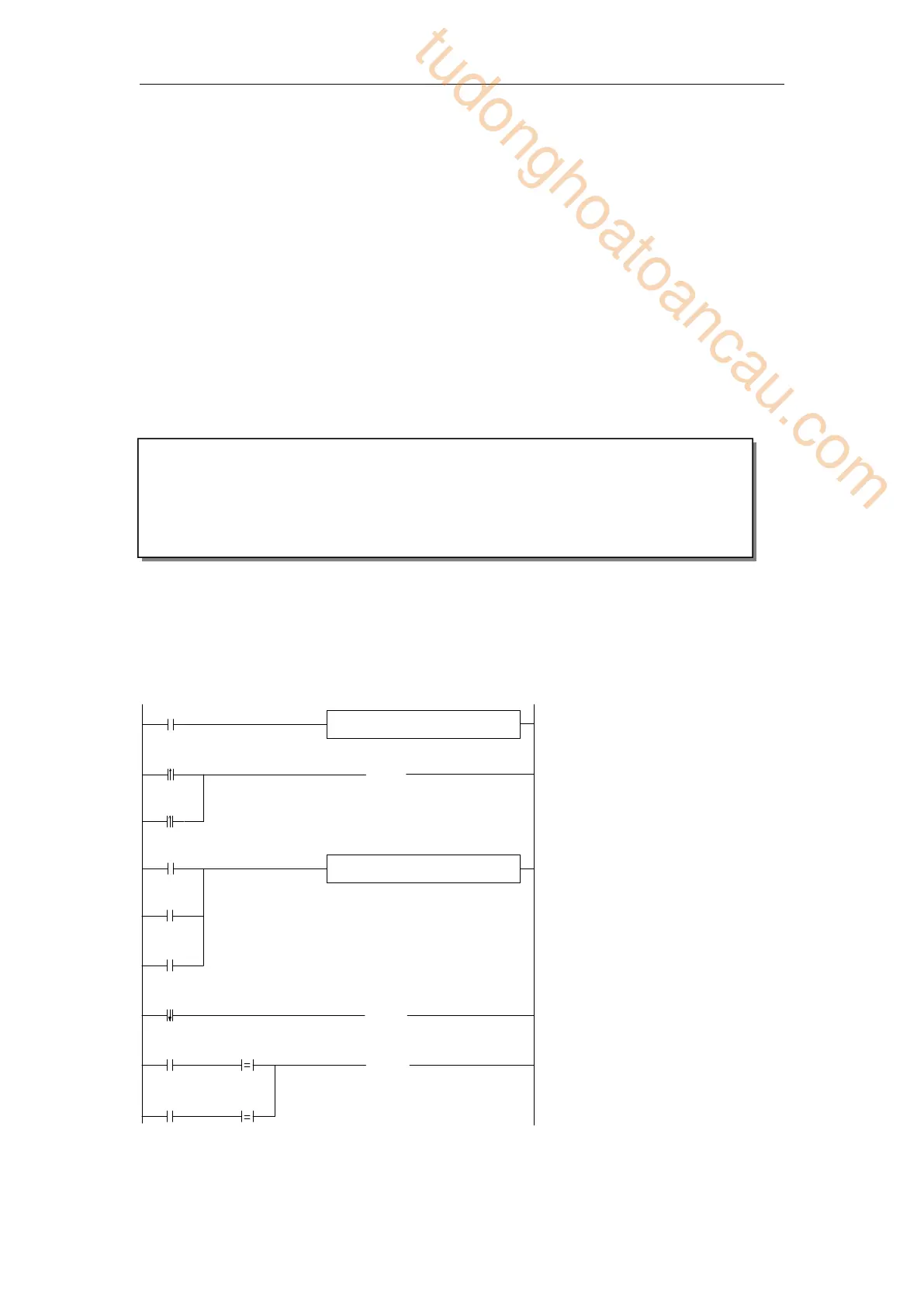

7-7 Application

Example 1:

PID control program is shown below:

MOV ID100 D10

SM0

M1

M2

( S )

HD2.7

M0

PID D0 D10 HD0 Y0

M1

M2

M2

( R )

HD2.7

HD2.8 HD09

( R )

M1

HD2.8

K0

HD09 K1

Temperature system: P (%) 2000 ~ 6000, I (minutes) 3 ~ 10, D (minutes) 0.5 ~ 3

Flux system: P (%) 4000 ~ 10000, I (minutes) 0.1 ~ 1

Pressure system: P (%) 3000 ~ 7000, I (minutes) 0.4 ~ 3

Liquid level system: P (%) 2000 ~ 8000, I (minute) 1 ~ 5

// Move ID100 content into D10

// auto tune mode, or set to autotune mode

after auto tune end

// start PID, D0 is target value, D10 is the

measured value, from HD0 is PID

parameters area; output PID result byY0

// PID control finish, close auto tune PID

mode

// if auto tune is successful, and overshoot is

permitted, close auto tune control bit, auto

tune will finish;

If auto tune turns to be manual mode, and

overshoot is not permitted, close auto

tune control bit.

tudonghoatoancau.com

Loading...

Loading...