4 Preparation before Replacing Parts

DX100 4.1 Creating a Check Program

4-3

• Change in the combination of the manipulator and DX100

• Replacement of the motor or absolute encoder

• Clearing stored memory (by replacement of NCP01 circuit board,

weak battery, etc.)

• Home position deviation caused by hitting the manipulator against a

workpiece, etc.

4.1 Creating a Check Program

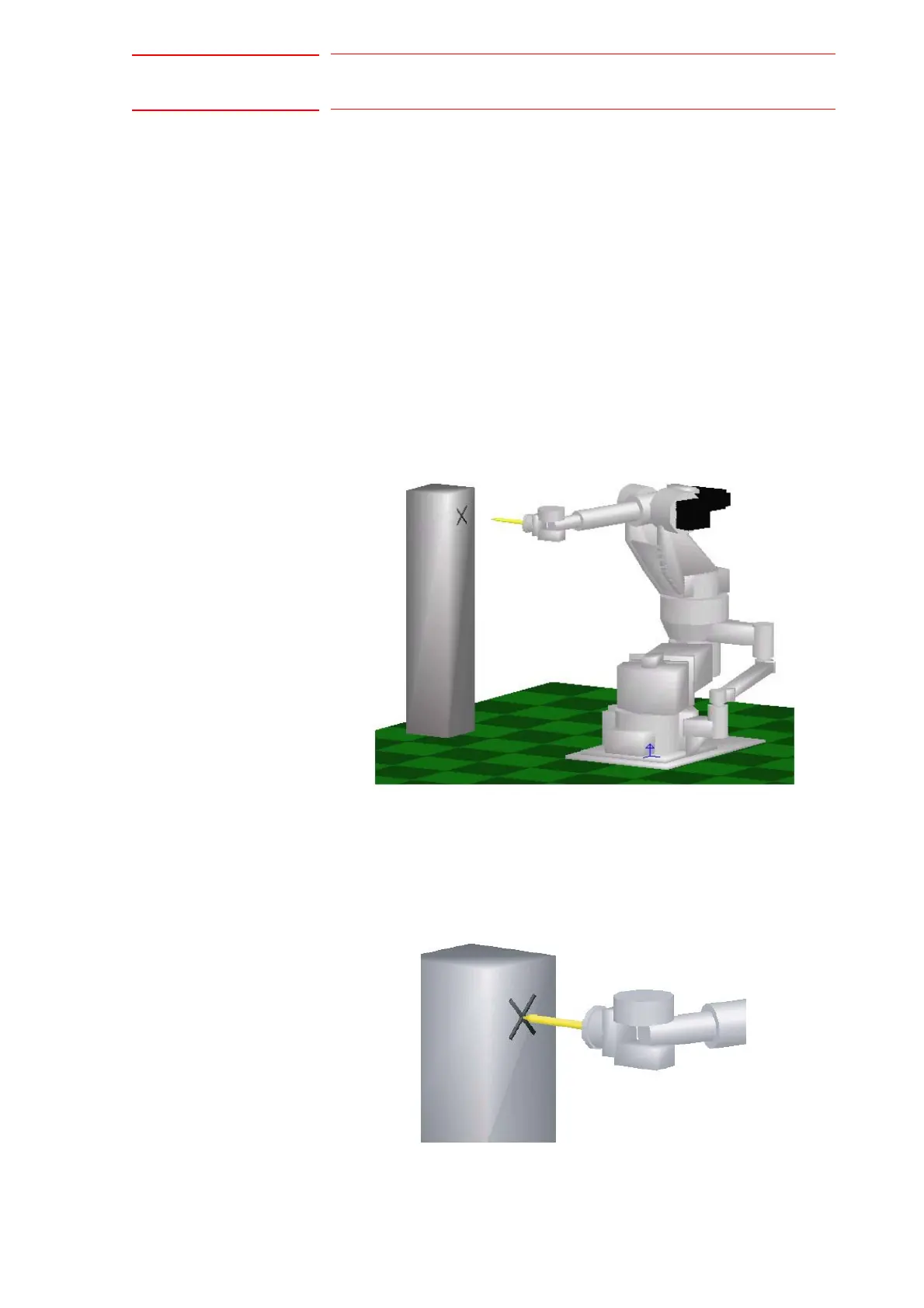

To check position deviation whenever necessary, create a program in

which a check point is taught (the job for the check point). In the job for the

check point, teach two points; one as a check point and the other as the

point to approach the check point. This program checks for any deviation

between the tool tip position and the check point.

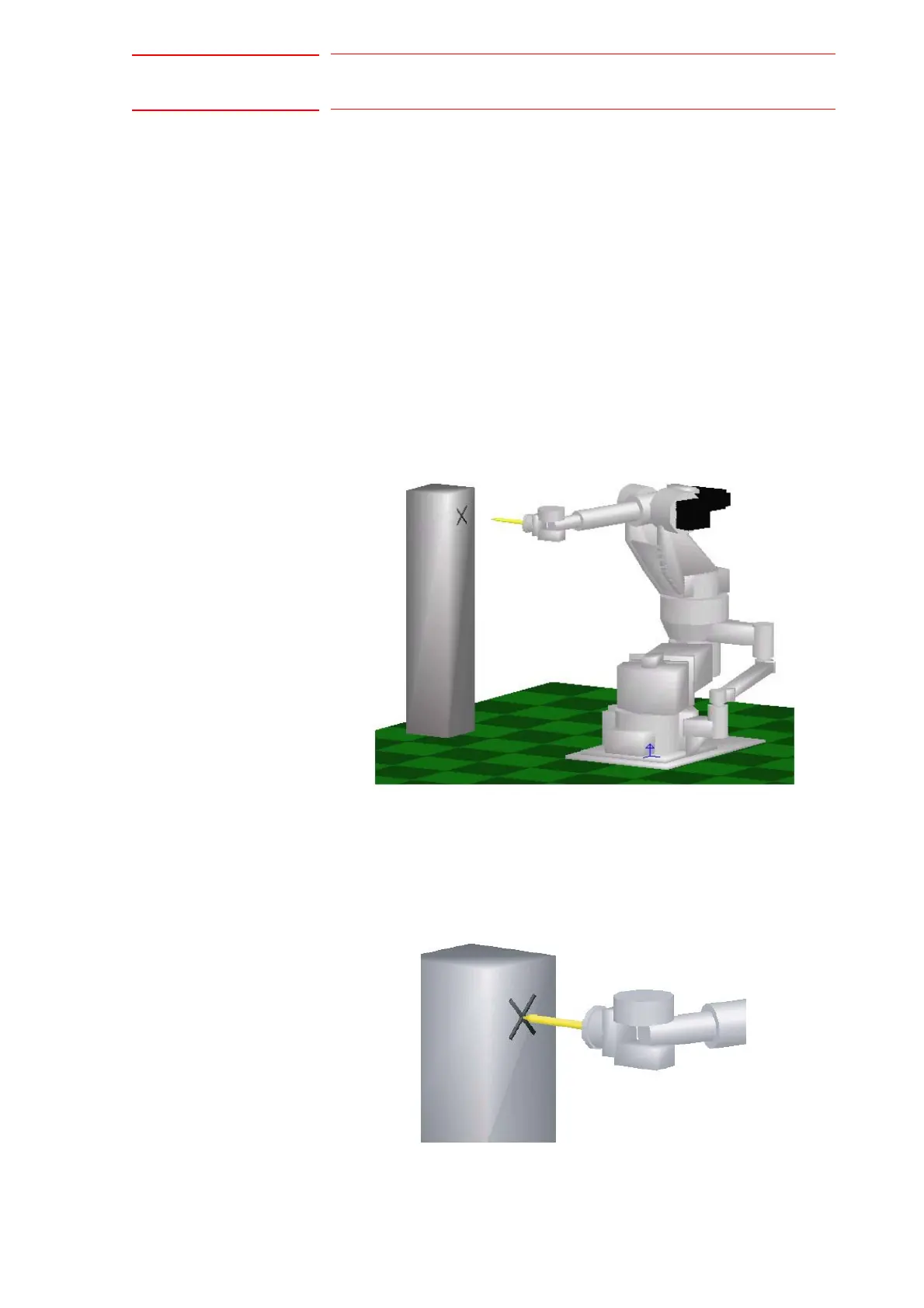

Fig. 4-1: <Enlarged View>

Loading...

Loading...