2 - 12 DS457-XX20004ZZWW Fixed Mount Imager Integration Guide

Window Coatings

Table 2-3 lists some exit window manufacturers and anti-reflection coaters.

Anti-Reflection Coatings

Anti-reflection coatings can be used to achieve maximum working range and to improve the range of acceptable

window positions. However, they are expensive. AR coatings also have very poor abrasion and scratch

resistance, making only single-side AR coating practical (the AR coated side of the window faces the interior of

the imager).

Polysiloxane Coating

Apply polysiloxane type coatings to plastic surfaces to improve the surface resistance to both scratch and

abrasion. Typically, you apply these by dipping, then air-drying in an oven with filtered hot air.

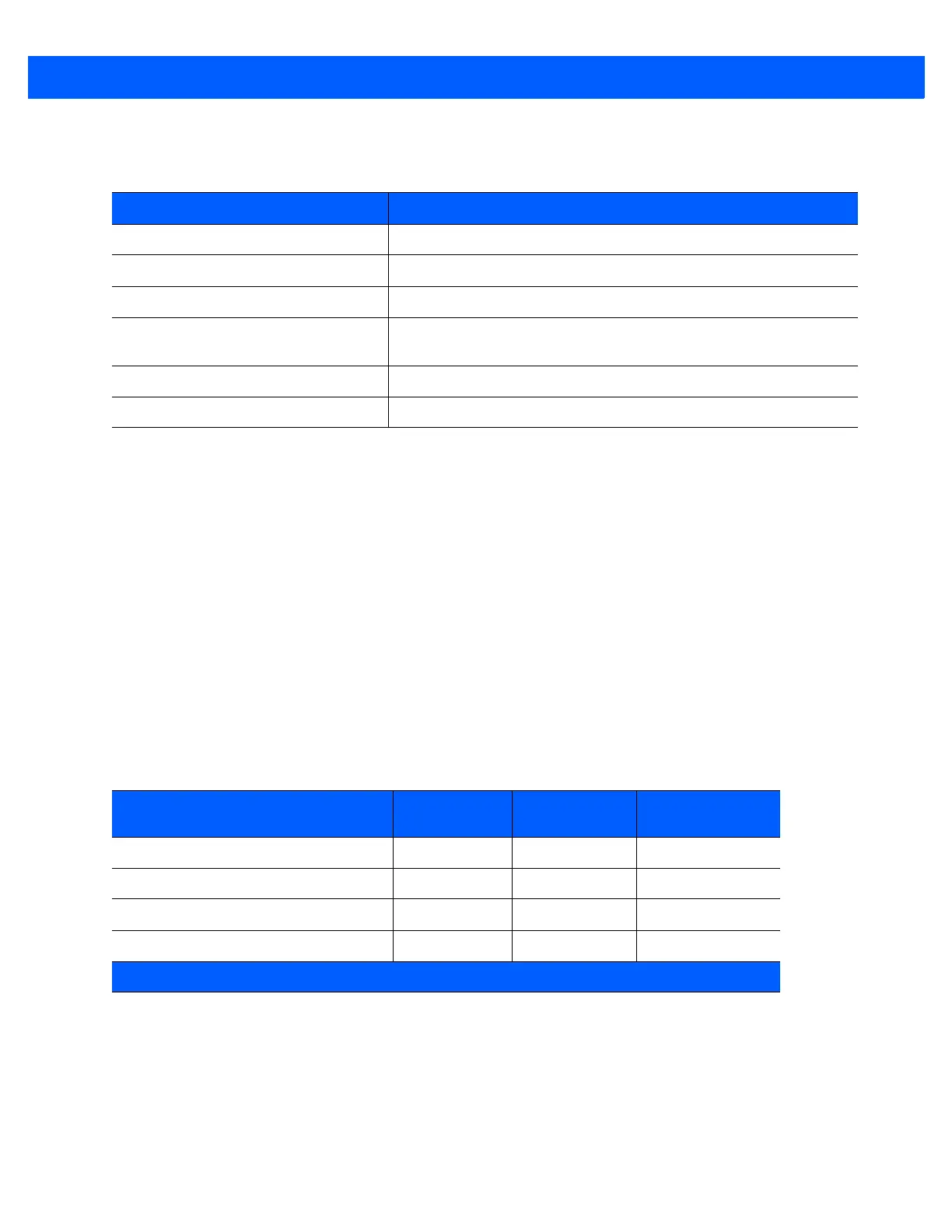

Table 2-1

Suggested Window Properties

Property Description

Material Clear cell-cast acrylic.

Spectral Transmission 85% minimum at 400 - 700 nm.

Thickness 0.059 ± 0.005

Wavefront Distortion (transmission) 0.2 wavelengths peak-to-valley maximum over any 0.08 in.

diameter within the clear aperture.

Clear Aperture To extend to within 0.04 in. of the edges all around.

Surface Quality 60-20 scratch/dig

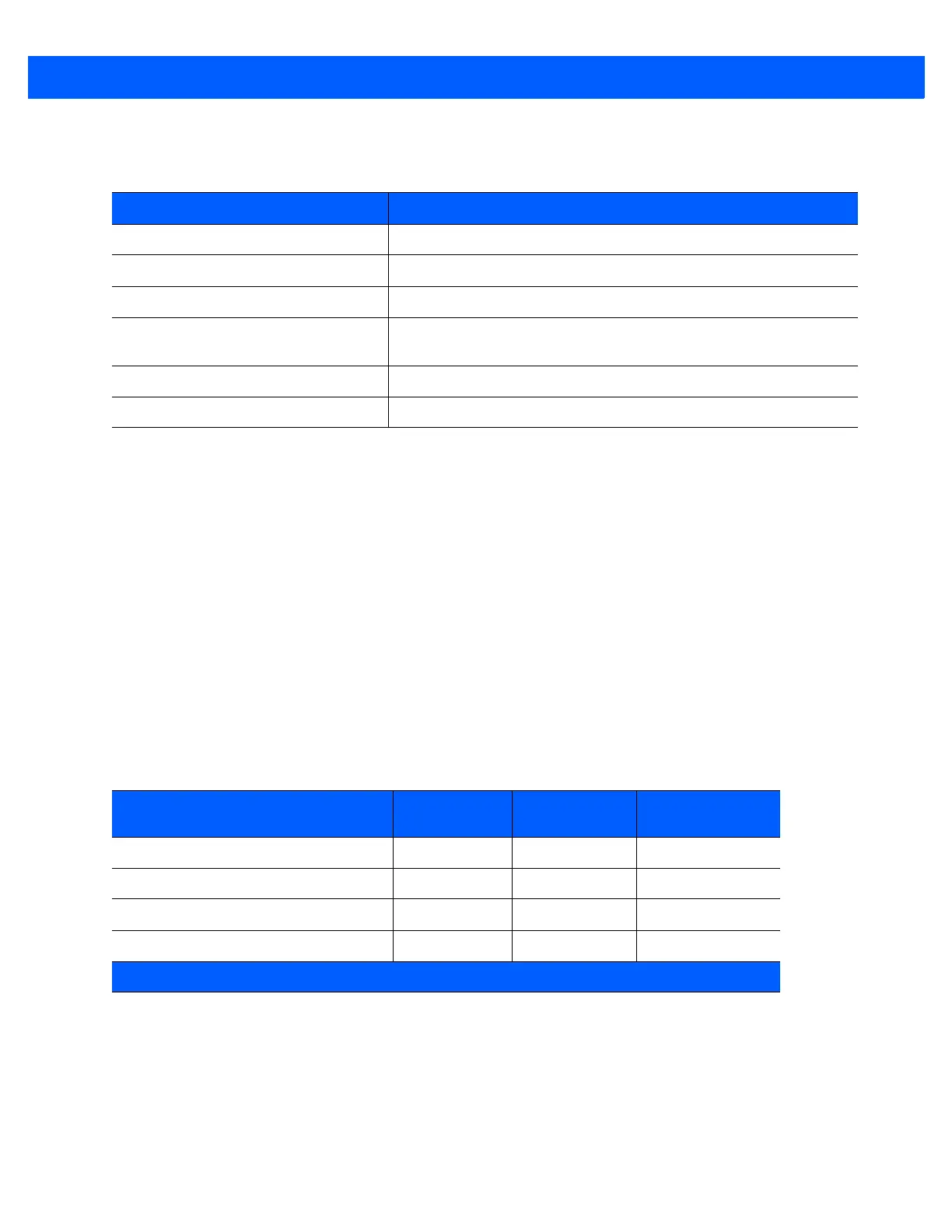

Table 2-2

Taber Test Results on Common Exit Window Materials

Sample

Haze 100

cycles

Haze 500

cycles

Abrasion

Resistance

Chemically Tempered Float Glass 1.20% 1.50% Best

PMMA with Polysiloxane Hardcoat 3% 10%

ADC 5% 30%

PMMA 30% Worst

* All measurements use a 100 gram load and CS-10F abraser.

Loading...

Loading...