Rockwell Automation Publication 6000-TD004D-EN-P - November 2017 41

Functional Descriptions Chapter 1

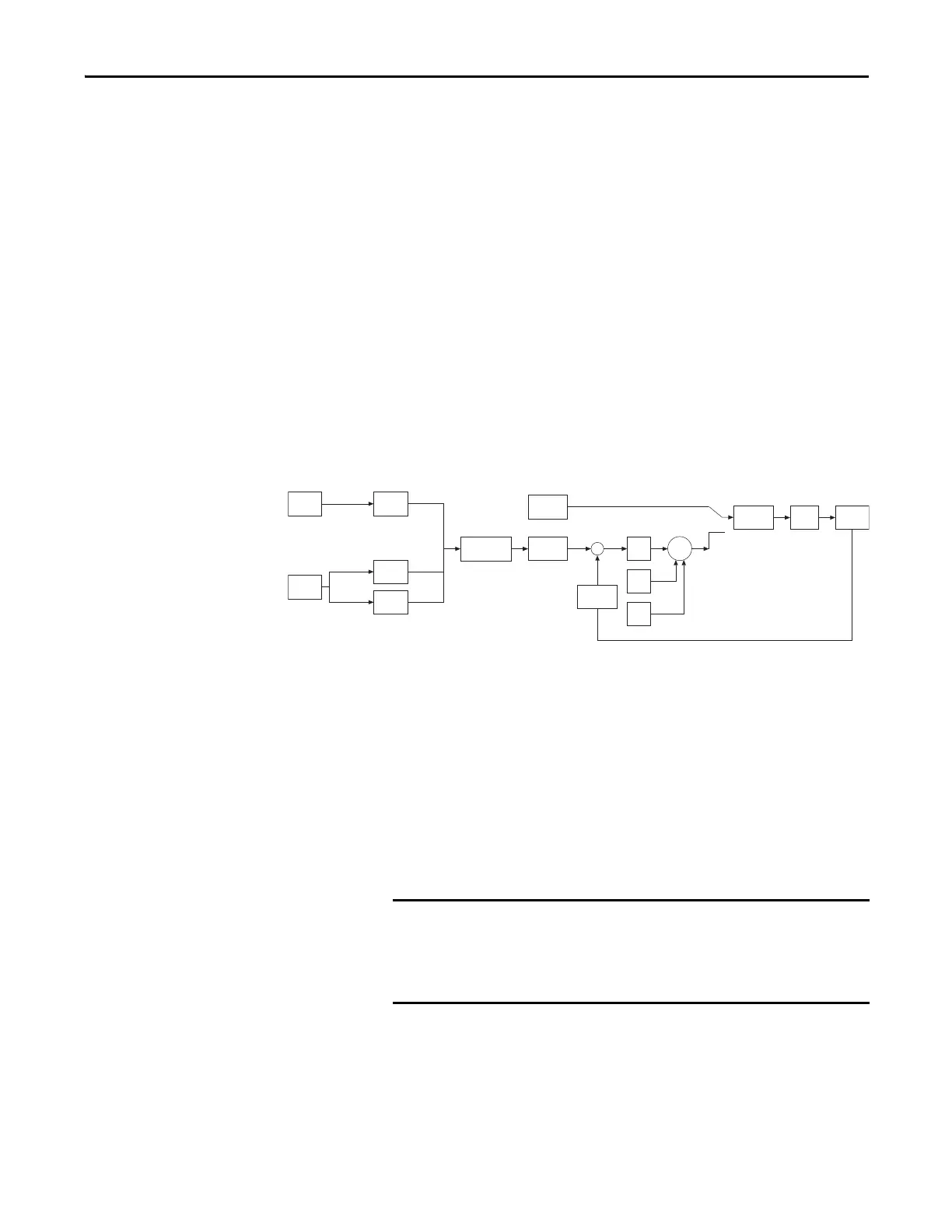

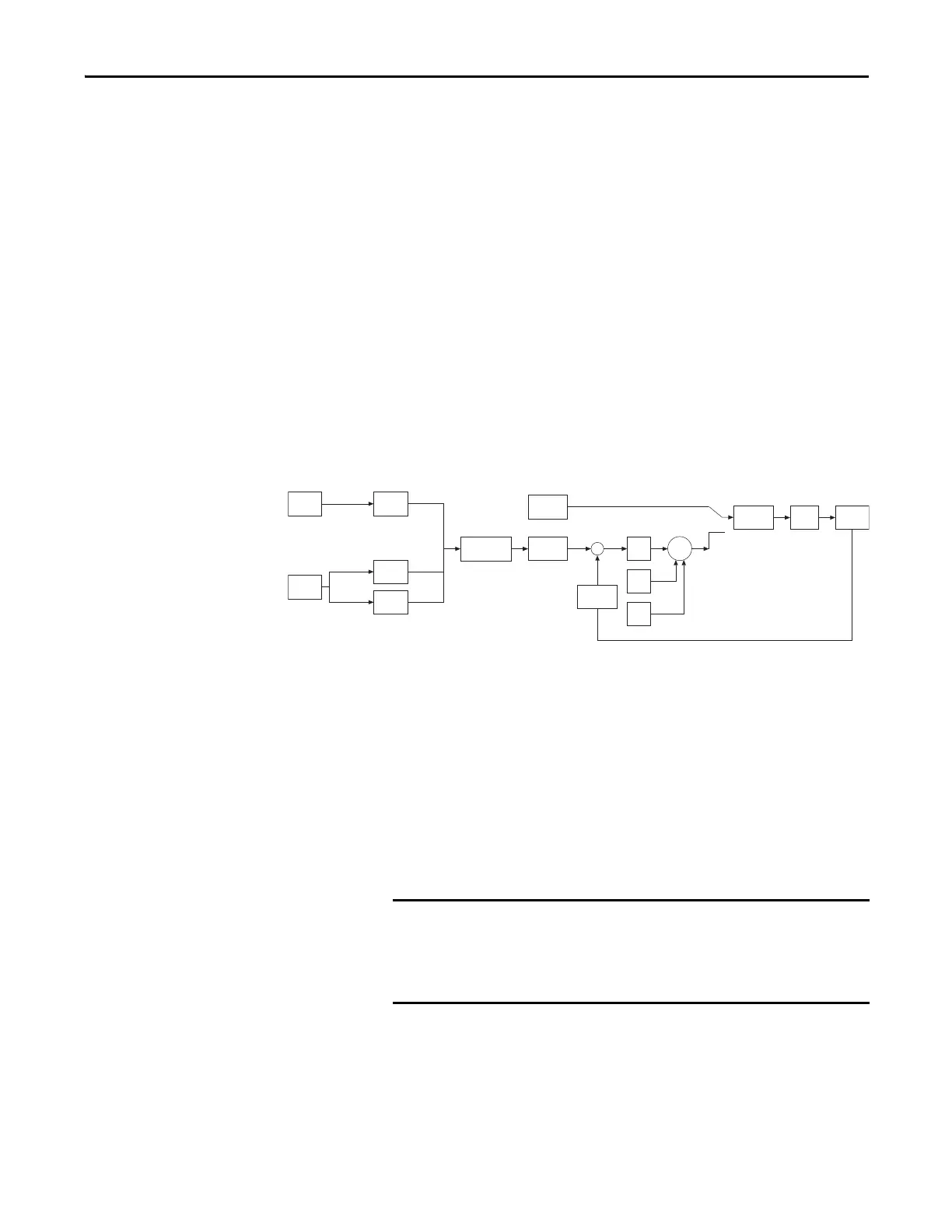

PID Function

This function allows you to control the production process and process feedback

signal to the drive to achieve PID process control.

To use the PID function:

1. Set PID Control Enable (P486) to “1”.

There is only the negative feedback function, there is no positive feedback

function.

2. Select the reference signal

If PID Control Enable is set to “1”, the frequency reference channel is

disabled and the PID reference channel is enabled. In the hardware, both

frequency reference and PID reference share the same channel.

3. PID reference signal

The drive PID digital and analog reference signals are shown in the

following diagram.

a. Digital reference signal

When the drive is in the Local control method (Owner #1 Selection

(P475) = “1”), the signal is provided by the HMI and the data range is

from 0...100.0.

When the drive is in the Remote control method (Owner #2 Selection

(P476) = “15”), the signal is provided by communications and the data

range is from 0...1000 (1000 = upper range limit * 10).

b. Analog reference signal

When the drive is in the Remote control method (Owner #2 Selection

(P476) = “8”), the signal is provided by the 4-20 mA input.

P475=0

P476=15

P476=8

0.0...100.0 PID Function Switch

Negative Feedback

0...1000

4-20 mA

HMI

Normalization

Comm

Analog

Local

Remote

P

I

D

Drive

PID

Reference

Frequency

Reference

Frequency

Reference

Control

Target

Feedback

Take note of the following:

• Failure during frequency-to-power conversion and power-to-

frequency conversion functions.

• Fault automatic conversion function is retained.

Loading...

Loading...