208 Rockwell Automation Publication 6000-TD004D-EN-P - November 2017

Chapter 3 Fault Messages

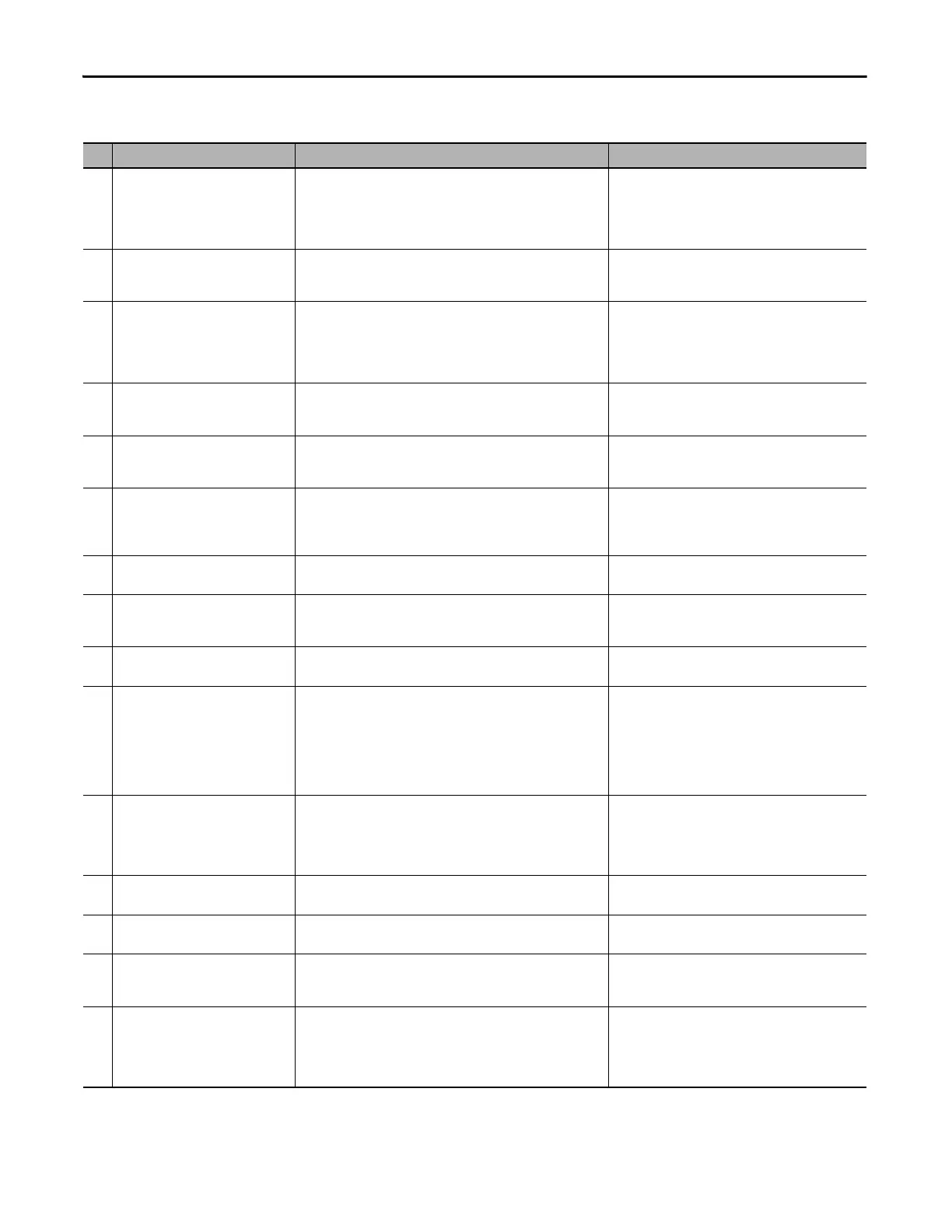

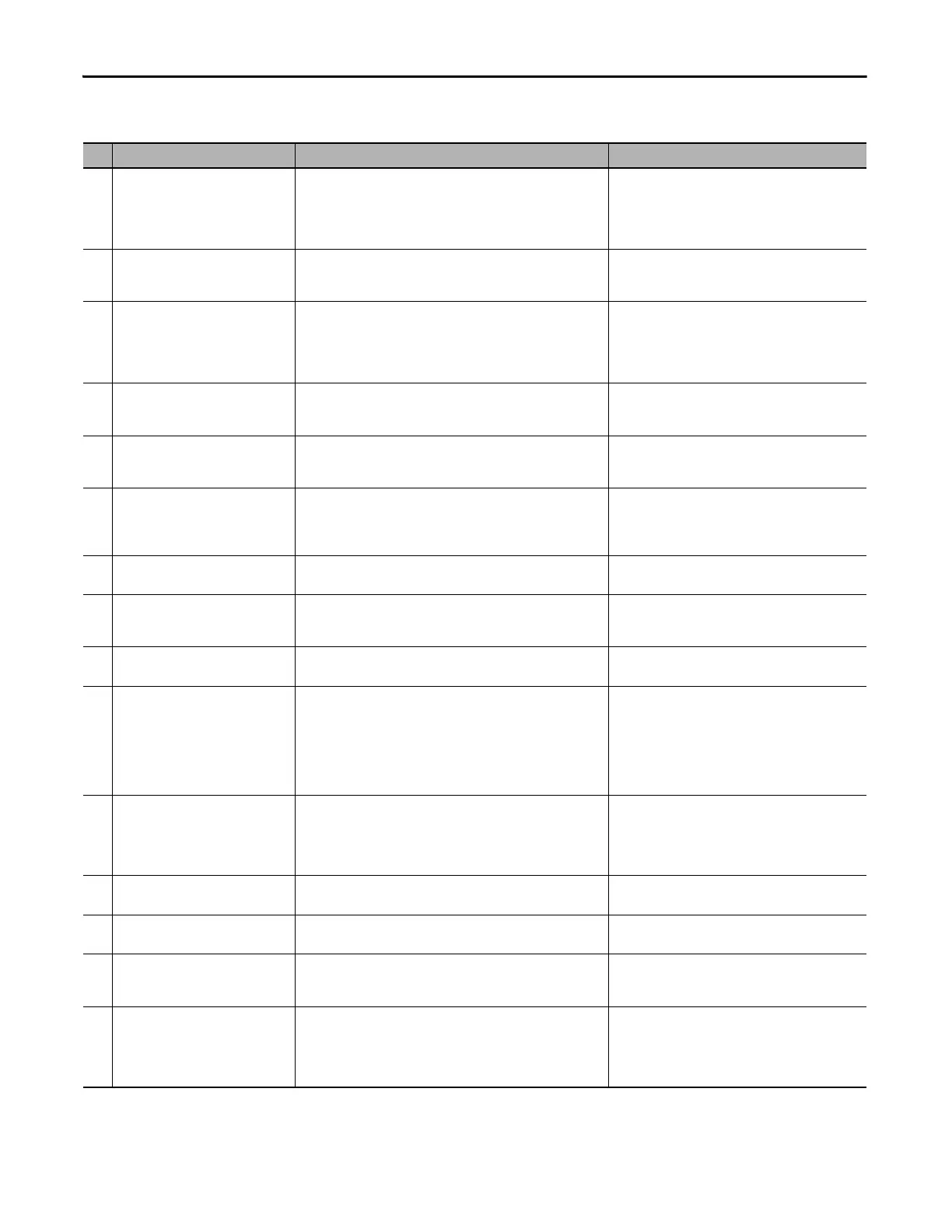

Power Cell Faults

No. Power Cell Fault Message Description Recommended Action(s)

103 IGBT Over Current In Power Cell #N The working current of the IGBT has exceeded the preset threshold for

a certain duration (depending on hardware value).

This fault means the working current of power cell #N is too high.

• Check if output over current or short circuit on the

motor side is present.

• Check the connection between the IGBT gate and

PCCB.

• Check if IGBT or PCCB is damaged.

104 Capacitor Abnormal in Power Cell #N The deviation between the actual voltage and the rated voltage on the

detected capacitor is larger than the hardware level in DC-link.

• Check if capacitor is short circuited or damaged.

• Check if connection between MVB board and

capacitors in DC-link is disconnected.

105 Input Over Voltage in Power Cell #N The sampled voltage of DC-link has exceeded the over voltage

threshold.

• Check parameters Acceleration Time (P401) and

Deceleration Time (P399) are set correctly.

• Check if voltage on line side is over threshold or

fluctuation is present.

• Check if PCCB is damaged.

106 DC Bus Undervoltage in Power Cell #N The sampled voltage of DC-link is lower than the under voltage

threshold.

• Check if voltage on line side is under threshold or

fluctuation is present.

• Check if PCCB is damaged.

107 Communication Error in Power Cell #N The signal sent from the power cell control board is lost. • Check if fiber optic cable in power cell #N is connected

properly, disconnected, or damaged.

• Check if PCCB is damaged.

108 No PWM Pulse for IGBT in Power Cell #N A certain duration has passed with no pulse signal sent from the

control box.

• Check if fiber optic cable in power cell #N is connected

properly, disconnected, or damaged.

• Check if power cell control board is damaged.

• Check PWM board.

109 Bypass Hardware Fault in Power Cell #N The feedback signal from the bypass circuit is wrong after a power cell

bypass command is received in power cell #N.

• Check the bypass circuit in power cell #N.

• Check the IGBT in power cell #N.

110 Communication Link Fault In Power Cell

#N

There is no communication link between the PCCB board and control

box in power cell #N

• Check if fiber optic cable in power cell #N is connected

properly, disconnected, or damaged.

• Check the power cell control board.

111 PCCB Version Not Compatible in Power

Cell #N

The hardware and software version of the PCCB board in power cell #N

are incompatible.

Check the PCCB board in power cell #N.

112 Over Temperature in Power Cell #N The temperature switch is changed from open to close if the

temperature of the heat sink exceeds the threshold.

• Check if the ambient temperature is greater than the

threshold.

• Check if there is power supply to the fans.

• Check if the temperature relay and cable is damaged.

• Check if one of these parts is blocked: air tunnel, inlet

filter, outlet, and so on.

• Check if there is over current in the power cell.

113 Power Cell #N Failed To Bypass The power cell bypass feedback signal delay has exceeded the duration

set in Power Cell Bypass Upper Limit For Bypass Feedback Time (P043).

•

Check hardware of the bypass power cell.

• Check parameter Power Cell Bypass Upper Limit For

Bypass Feedback Time (P043) is set correctly and if the

power cell can perform the bypass and receive the

feedback signal within the duration.

114 One Phase Lost in Power Cell #N The signal of phase loss detection circuit is abnormal when any phase

is lost.

• Check the voltage on the line side for fluctuations.

• Check if fuse in the power cell is damaged.

115 Two Phase Lost in Power Cell #N The signal of phase loss detection circuit is abnormal when two or

more phases are lost.

• Check the voltage on the line side for fluctuations.

• Check if fuse in the power cell is damaged.

116 Bypass Failure (OV) in Power Cell #N The power cell bypass was triggered but the bypass hardware failed

and no feedback signal was sent to the control board. The drive

continued to run and caused a DC bus over voltage trip to occur.

• Check if the power cell has a bypass circuit and for

damage.

• Check hardware of the power cell bypass circuit.

117 Over Temperature Time Out in Power

Cell #N

The over temperature fault has exceeded the duration set in Power Cell

Bypass Upper Limit For Bypass Feedback Time (P057) after being trigged

by the power cell bypass due to power cell over temperature.

• Check if there is power supply to the fans.

• Check if temperature sensor on heat sink is working.

• Check if one of these parts is blocked: air tunnel, inlet

filter, outlet, and so on.

• Check if there is over current in the power cell.

Loading...

Loading...