180 MAX Operation & Service Manual180 Section7:Troubleshooting MAX Operation & Service Manual

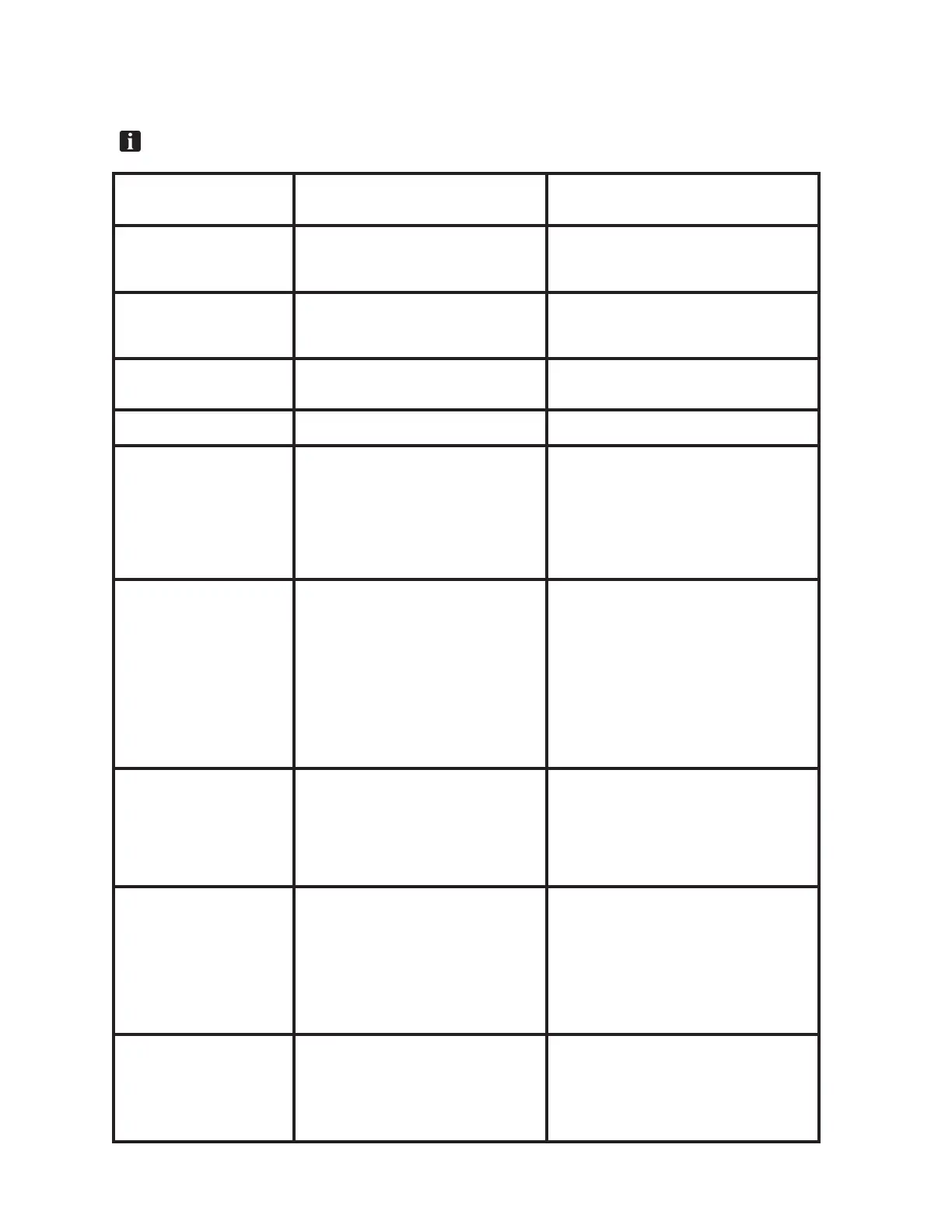

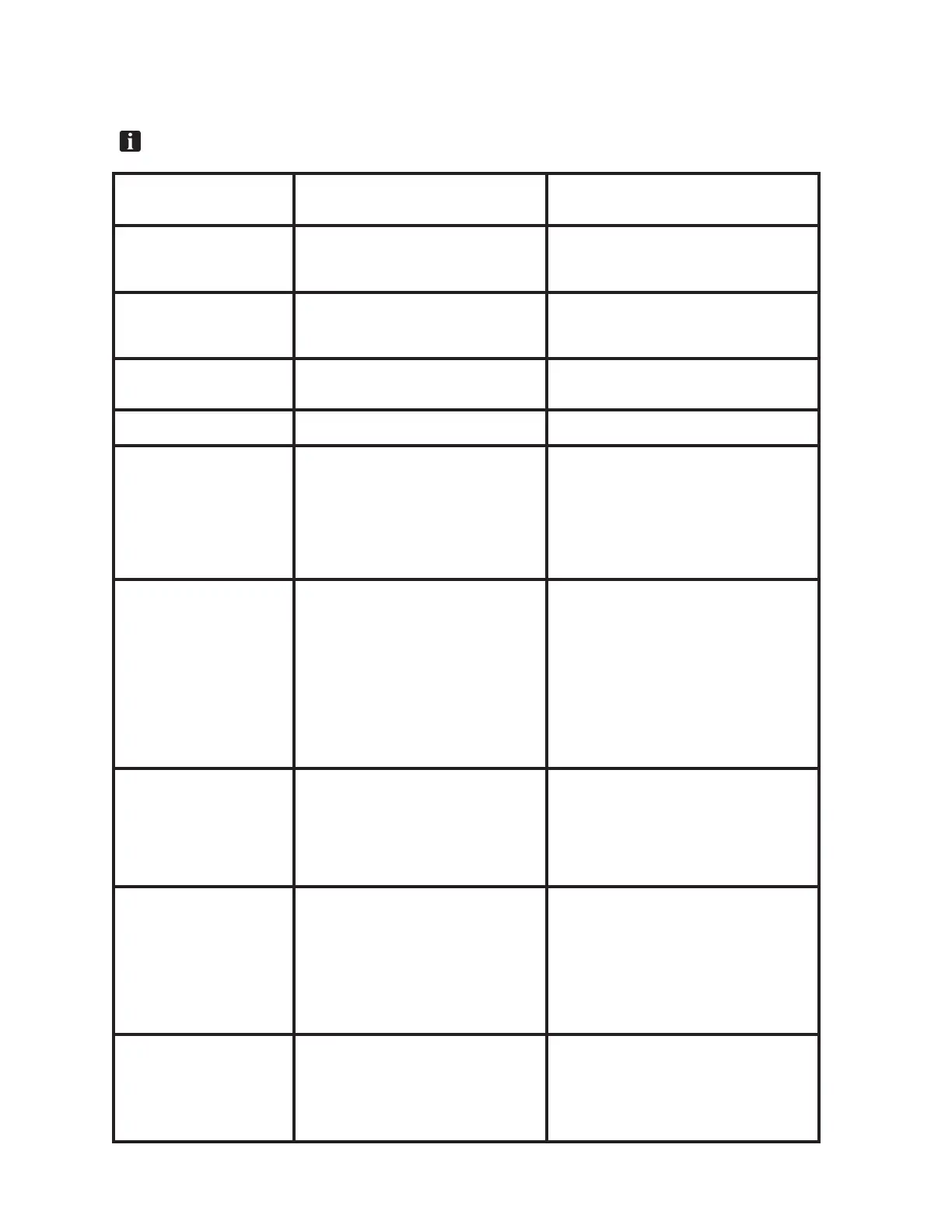

Error Messages - Table 7-13:

Other error messages

NOTE::VerifyerrorsourcethroughTabletdiagnostics.

These messages begin...

The lane machine is not ready

for operation…

Potential problem Action

An error occurred during the

pattern parameter download

1. Changes to the existing pattern param-

eters did not download correctly to the

machine

1. Option 1: Exit the screen and try again

Option 2: Remove and restore power and

try again

Invalid pattern parameters

were sent to the controller or

the pattern parameter data

is bad

1. The lane machine cannot operate with

the current pattern parameters

1. Download the pattern again

2. Contact the BTS or your Brunswick installer

of the lane machine

Flash packet write error 1. The controller could not write the pattern

data to the ash memory

1. Turn off the power, restore the power and try

running again.

An error occurred during the

pattern download

1. The desired lane conditioning pattern did

not download correctly to the lane machine.

1. Turn off the power, restore the power and

download the pattern again.

Power lost 1. Machine is unplugged, the power switch

on the enclosure is off, or the emergency

stop switch has been depressed.

2. The battery or power supply connection

is loose

3. Defective machine control pcb.

1. Check that the power cord is plugged into a

working outlet and that all power switches are

turned on.

2. Check the “Battery In” connection on the

electronic enclosure

3. Contact the BTS or your Brunswick installer

of the lane machine.

The cleaner pressure is not

set properly. The cleaner pres-

sure is low.

1. The pressure for the cleaner is set below

14 psi.

2. Pre-pump lter is dirty.

3. Tubing not pressed into the ttings com-

pletely or not trimmed at a 90 degree angle

- allowing air into the system.

1. Follow the adjustment; Cleaner Pinch Valve

Adjustment

2. Remove bowl lter, inspect, clean or replace

as required.

Note: Debris accumulates on the inside of

thisscreenlterandmaynotbeviewable

from the outside.

3. Check tubing connections - reseat in the

tting or re-trim as needed.

The controller board did not

respond within the required

time period.

1. The lane machine took too long to com-

plete the lane

2. The conditioner pump took to long to

pressurize the system

3. The operator did not respond to a ma-

chine command within the allowable time

1. Check pin deck travel and adjust EOL travel

speed or base voltage

2. The conditioner pump is obstructed or failed

3. Restart lane preparation

Limited Lanes Remaining! 1. The battery voltage is getting low 1. Determine if you are close enough to nish

the lanes (2-3 lanes from nishing)

2. Plug in the battery charger to charge the

battery

3. Disconnect the Battery cable from the

electrical enclosure, connect the AC/DC power

supply to the electrical enclosure and plug in

the AC power cord.

Battery voltage is too low to

run lanes

For the selected battery type, the voltage is

too low to continue running the lanes

1. Plug in the battery charger to charge the

battery

2. Disconnect the Battery cable from the

electrical enclosure, connect the AC/DC power

supply to the electrical enclosure and plug in

the AC power cord.

Loading...

Loading...