MAX Operation & Service Manual 183MAX Operation & Service Manual Section7:Troubleshooting183

Table 7-14 provides a list of warning messages with potential remedies. If you’re unable to resolve a

problem, please contact your Brunswick Distributor or Brunswick Technical Support (BTS) in the

United States at 1-800-YES-BOWL, or internationally at 231-725-4966. For non emergency support,

e-mail techsupport@brunwickbowling.com

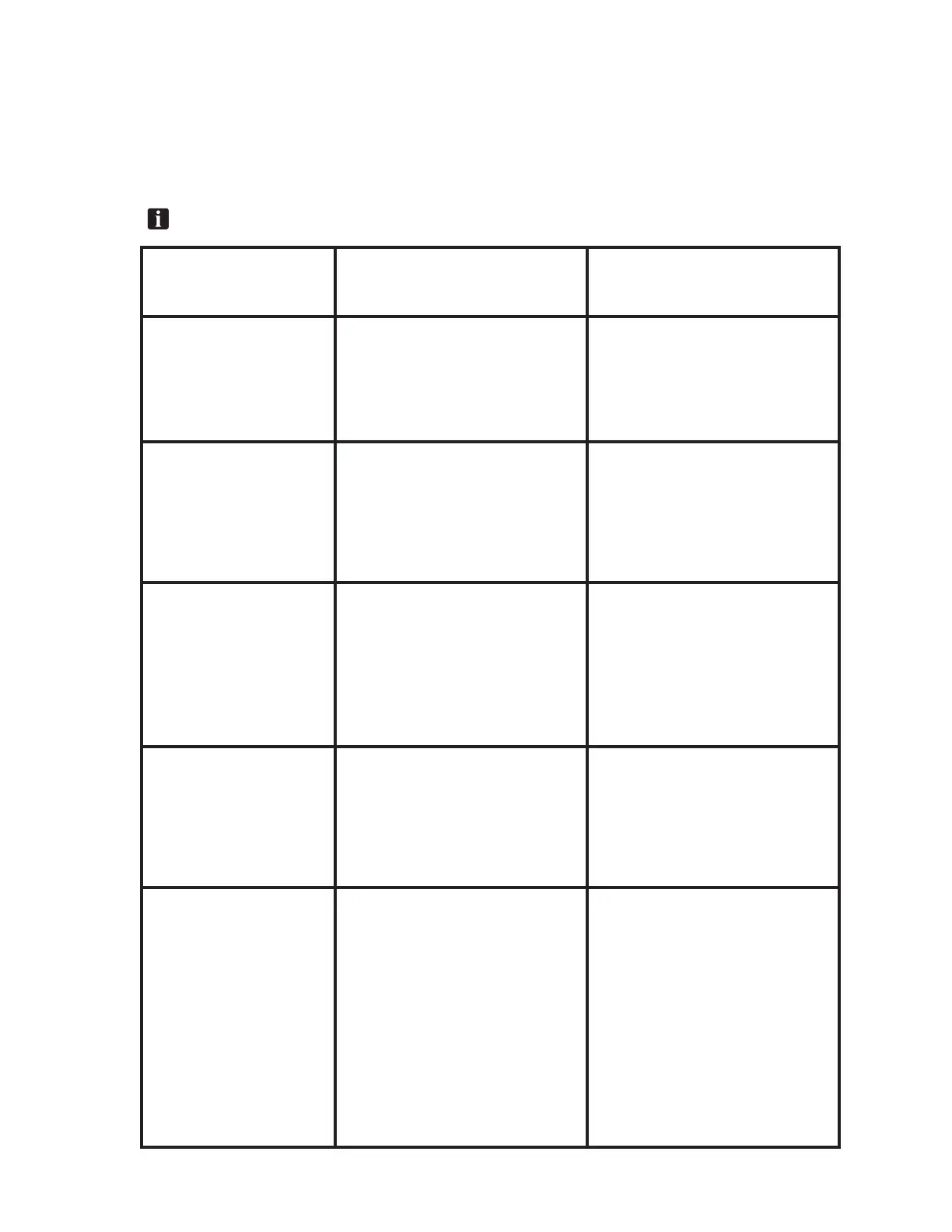

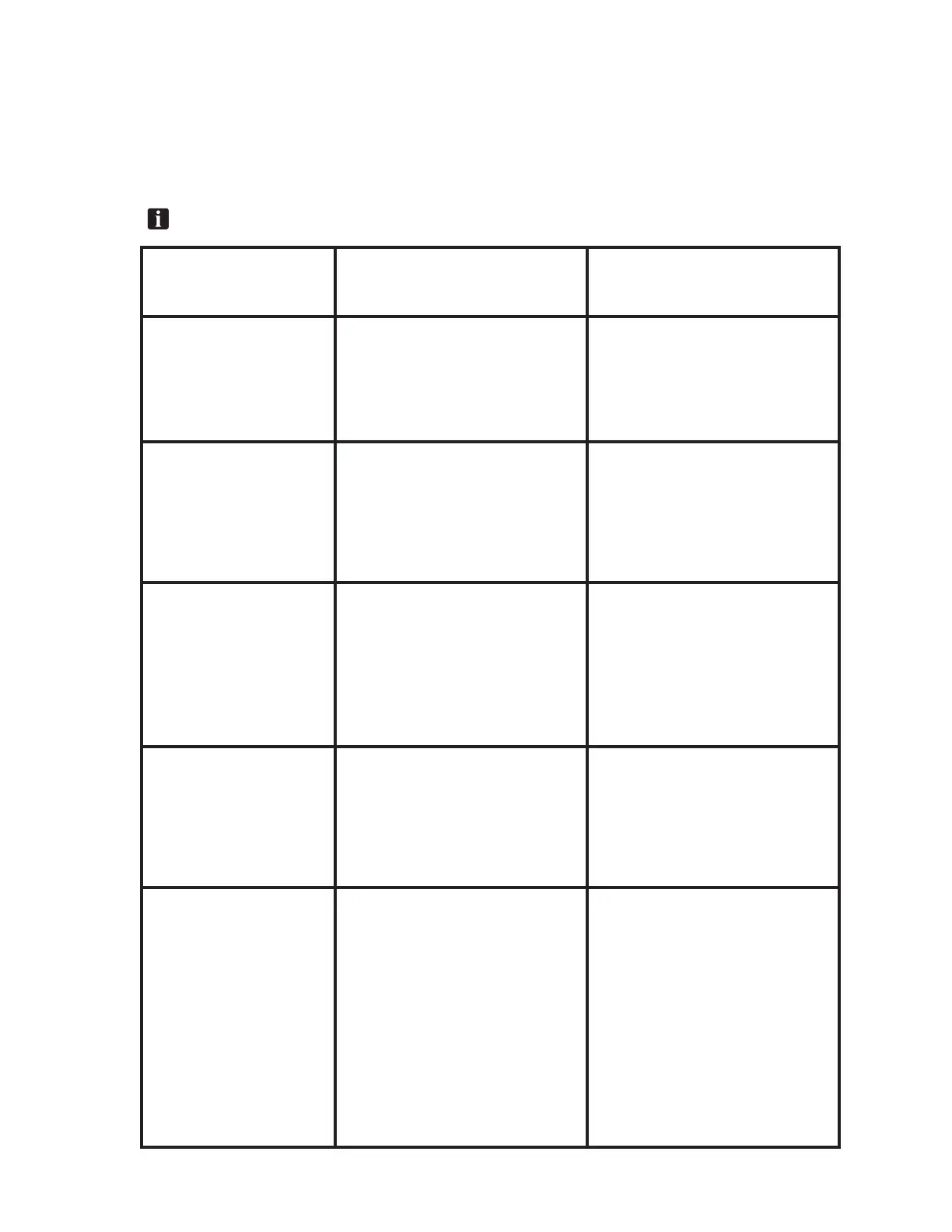

Warning Messages - Table 7-14.

NOTE:VerifyerrorsourcethroughTabletdiagnostics.

These messages begin...

The lane machine is not ready

for operation…

Potential problem Action

The oil level is low. Add more oil

to the tank.

1. Conditioner Level

2. Level sensor is unplugged at the tank or

electronic enclosure

3. Level sensor has failed

1. Add conditioner to the conditioner supply

tank until the bottom of the tank opening

2. Reconnect the cable

3. Verify sensor function using Tablet diag-

nostics and replace if necessary

The cleaner level is low. Add

more cleaner to the tank

1. Cleaner level is low

2. Level sensor is unplugged at the tank or

electronic enclosure

3. Level sensor has failed

1. Add cleaner to the cleaner supply tank to

the bottom of the tank opening

2. Reconnect the cable

3. Verify sensor function using Tablet diag-

nostics and replace if necessary

The oil temperature is too low

(Only occurs when the “Tem-

perature cycle” function is turned

“ON”)

1. Conditioning system has not reached the

target temperature.

2. Temperature sensor or the heating ele-

ment is unplugged.

3. Temperature sensor or heating element

has failed

1. Press “OK” on the tablet to bypass mes-

sage and continue heating or allow system

to reach the target temperature

2. Reconnect the cable

3. Verify sensor or heating element using

Tablet diagnostics and replace if necessary

The oil temperature is too high 1. Conditioning system has exceeded the

target temperature

2. Heater is always on

1. Go to the System settings and turn

“OFF” the Temperature Cycle

2. Option 1: Check voltage going to heater

Option 2: Check LED function on motor

control board inside the electronic enclo-

sure

The end of the lane sensor was

elevated too early

The end of the lane sensor may

be faulty

1. End of lane sensor is out of adjustment

2. The machine is started too far from the

foul line or the rear lane distance sensor is

out of adjustment/binding

3. End of lane sensor is unplugged

1. Option 1: Check height and sensitivity

adjustments. The end of lane sensor may

be faulty. See Adjusting the end-of-lane

sensor for more information

Option 2: Check for excess gap between

lane panels and pin deck, missing plugs, or

gutters that are too high (raising the front

of machine). Have qualied maintenance

person address lane or gutter repairs.

2. Check Lane Length log le and rear

shaft and frame atness

3. Reconnect cables

Loading...

Loading...