9

Operation

94/130 ekr CON 100 – Installation and Operating Manual

IR2011/40 operating modes

Operating

Mode

Field of Application Features Measuring

Range

Standard

Scanning of different

homogeneous materials

(opaque or transparent)

■ Material setup by user

24mm

(±12mm)

Narrow

Scanning of different

homogeneous materials

(opaque or transparent)

■ Material setup by user

7mm

(±3,5mm)

Auto Setup

Scanning of different

homogeneous materials

(opaque or transparent)

■ Continuous sensor calibration due to

permanent automatic material setup

20mm

(±10mm)

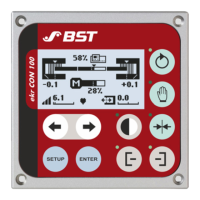

Marginal

Perforation

Scanning of material webs

with marginal perforation

(e.g. continuous forms)

Geometry of the marginal

perforation:

■ Reliable compensation of interfering

influences of the marginal perforation on

the web guiding control

■ Suitable for materials with circular or

rectangular tractor feed perforation

■ Scanning of the web edge is independent

of the shape and size of the holes.

Requirement: The edge distance D of the

tractor feed perforation is at least 4mm.

7mm

(±3,5mm)

Nonwoven

Scanning of fleece materials

(Nonwoven) with inhomogen-

eous material structure and

strongly varying transparency

■ Continuous sensor calibration due to

permanent automatic material setup

■ Automatic compensation of interfering

influences from gaps in the material

24mm

(±12mm)

Dynamic

Scanning of material webs

with highly dynamic web

position errors and high web

speeds

■ Very sensitive guiding behaviour with

extremely short response times

■ Sensor measuring value follows any web

edge position change without delay

24mm

(±12mm)

Loading...

Loading...