Commissioning

8

ekr CON 100 – Installation and Operating Manual 65/130

8.4 Setting the Motor Rotation Direction

When commissioning, you have to check the assignment of the

arrow keys to the positioning direction (motor rotation direction)

of the actuator.

The definition of the sensors (Sensor 1, Sensor 2, Sensor 3) is

described in chapter Designation of the Sensors, page 23.

Checking the motor rotation direction

WARNING

Danger of death from actuator movements!

During function tests, parts of your body may be crushed, cut or hit.

►

Make sure that no persons remain in the vicinity of the pivot /

traversing area of machine components that are positioned by

the actuator.

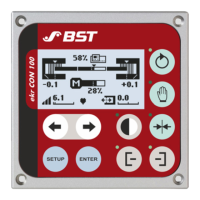

1. Press the Manual mode key.

The LED of the key will illuminate.

The controller switches to manual mode.

2. Press the left arrow key and observe the guiding device.

The guiding device must move in the direction of Sensor 1.

3. Press the right arrow key and observe the guiding device.

The guiding device must move in the direction of Sensor 2.

If only one CLS Pro600 line and contrast sensor (Sensor 3) is

connected to the controller then the guiding device must move

in the direction of the cable connection on the line and contrast

sensor.

If the guiding device moves in the opposite direction then you

have to reverse the motor rotation direction.

Reversing the motor rotation direction

The procedure depends on the type of actuator connected.

Actuator Procedure

EMS10,

EMS18,

EMS21,

EMS22,

ECOEMS22

Change DIL switch S1.1 on the processor board of

the controller

(see Setting the DIL Switches, page 64).

EMS23

Change DIL switch S4.6 on the processor board of

DriveModule160

(see separate operating instructions

DriveModule160, EDP no. MD.359).

Loading...

Loading...