SECTION 6 - AIR SYSTEM SERVICE

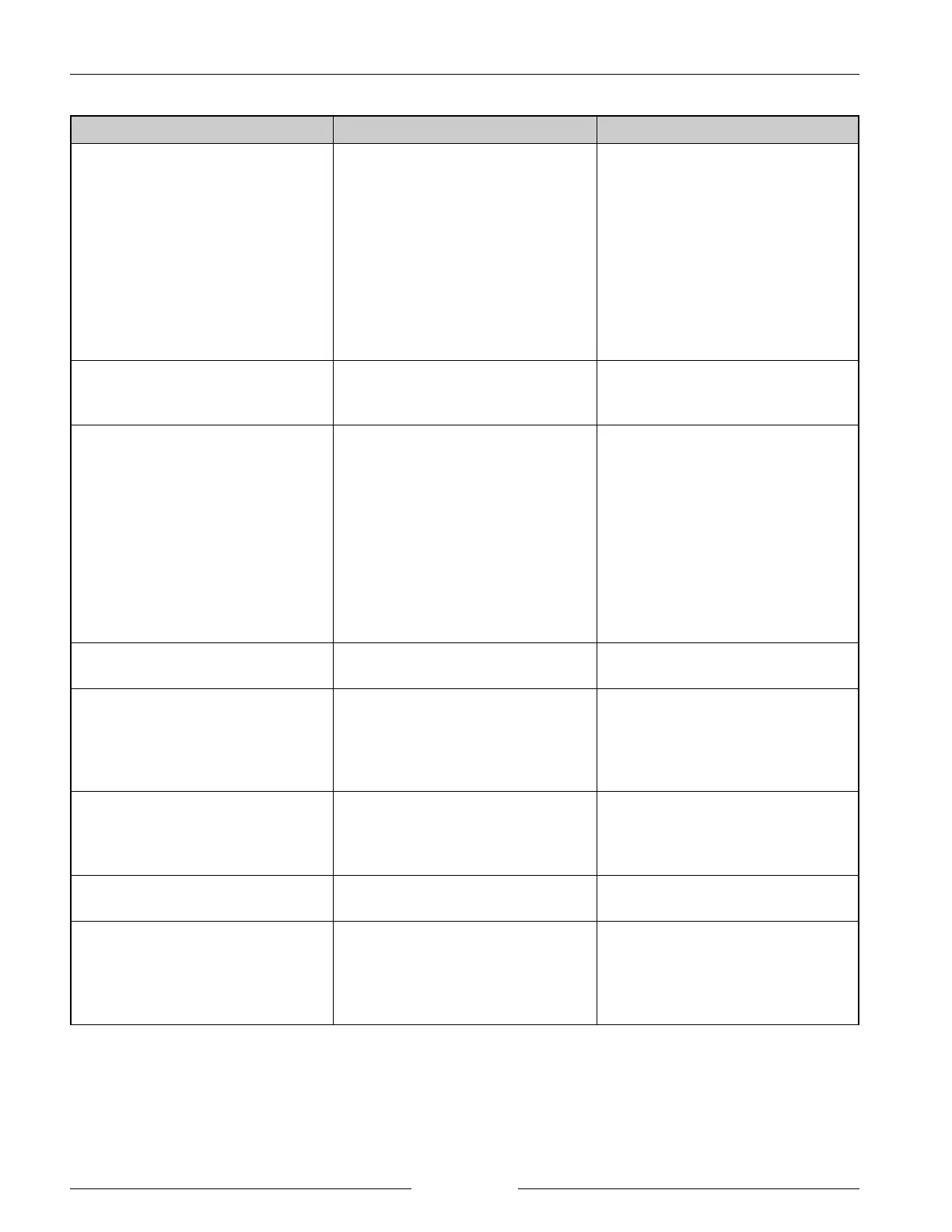

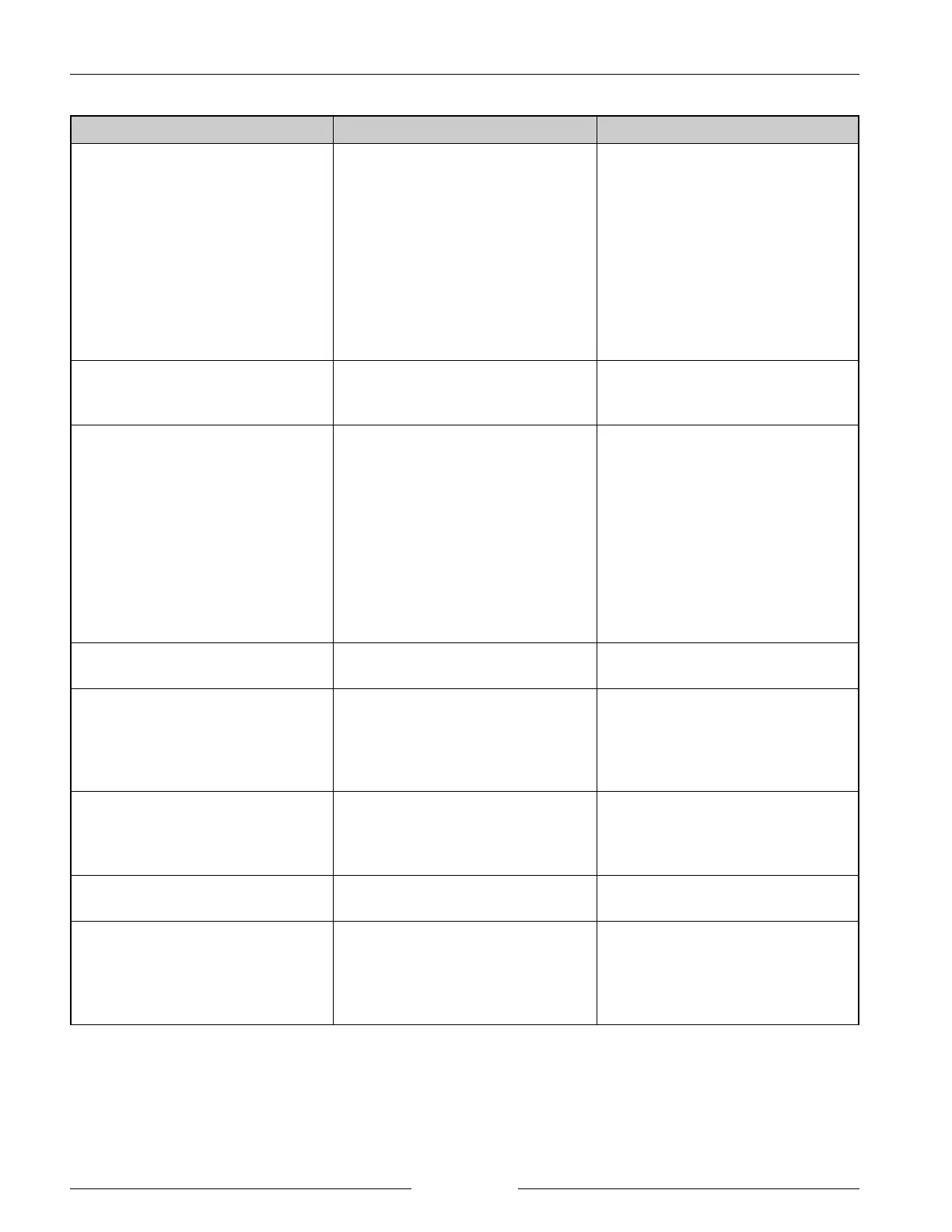

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

page 6-4

Lines are plugged - outside

(longest) lines only.

1. Line length differences are too

great.

2. Hoses make too many sharp

turns.

3. Hoses attached to weak supply

on manifold.

4. Unbalanced air flow (double

shoot system).

1. Remove excess length, or add

length to shortest lines.

2. Reroute to minimize corners.

3. Connect longest hoses toward

center of manifold.

4. See items above.

Final lines are plugged - just

outside of headers.

1. Insufficient product velocity

because lines are level or

sloping upwards.

1. Hoses from header should

slope downward.

Restriction in the header. 1. Product buildup.

2. Lumps lodged in the header.

3. Header assembly inserts

rotated.

4. Header assembly air hoses

inserted too far.

1. Inspect frequently. Clean as

required.

2. Dislodge. Use clean product.

Use debris screens.

3. Service and readjust the

secondary header.

4. Service and readjust the

secondary header.

Insufficient air velocity. 1. Discharge is blocked. 1. Clear lines at the seed boot.

Boots too restrictive.

Uneven product division. 1. Header ring loose or worn.

2. Riser tube not vertical.

1. Service and readjust the

secondary header.

2. Service and readjust the

secondary header.

Final line is plugged - between

header and opener.

1. Opener is plugged.

2. Hose is crimped.

1. Clear blockage in the seed

opener.

2. Repair damaged hose.

Seed openers are plugging. 1. Lumps of product are lodging

in the opener.

1. Clear all product buildup in the

seed opener.

Dirt or mud entering the opener. 1. Backing or turning with

openers in the ground.

2. Wet clay wrapping up behind

soil opener.

1. Lift seeding tool out of the

ground when turning.

2. Change openers; or operate in

drier conditions.

Loading...

Loading...