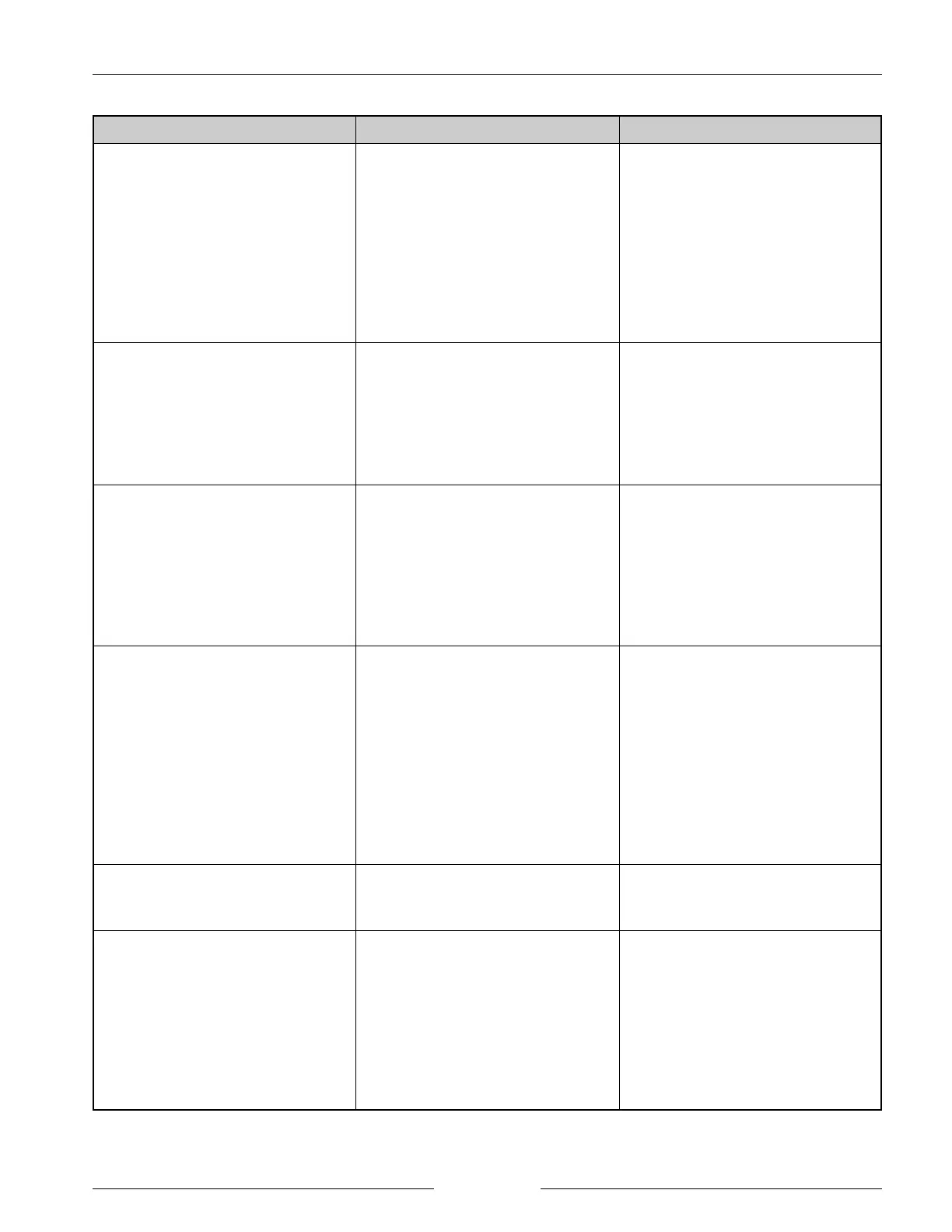

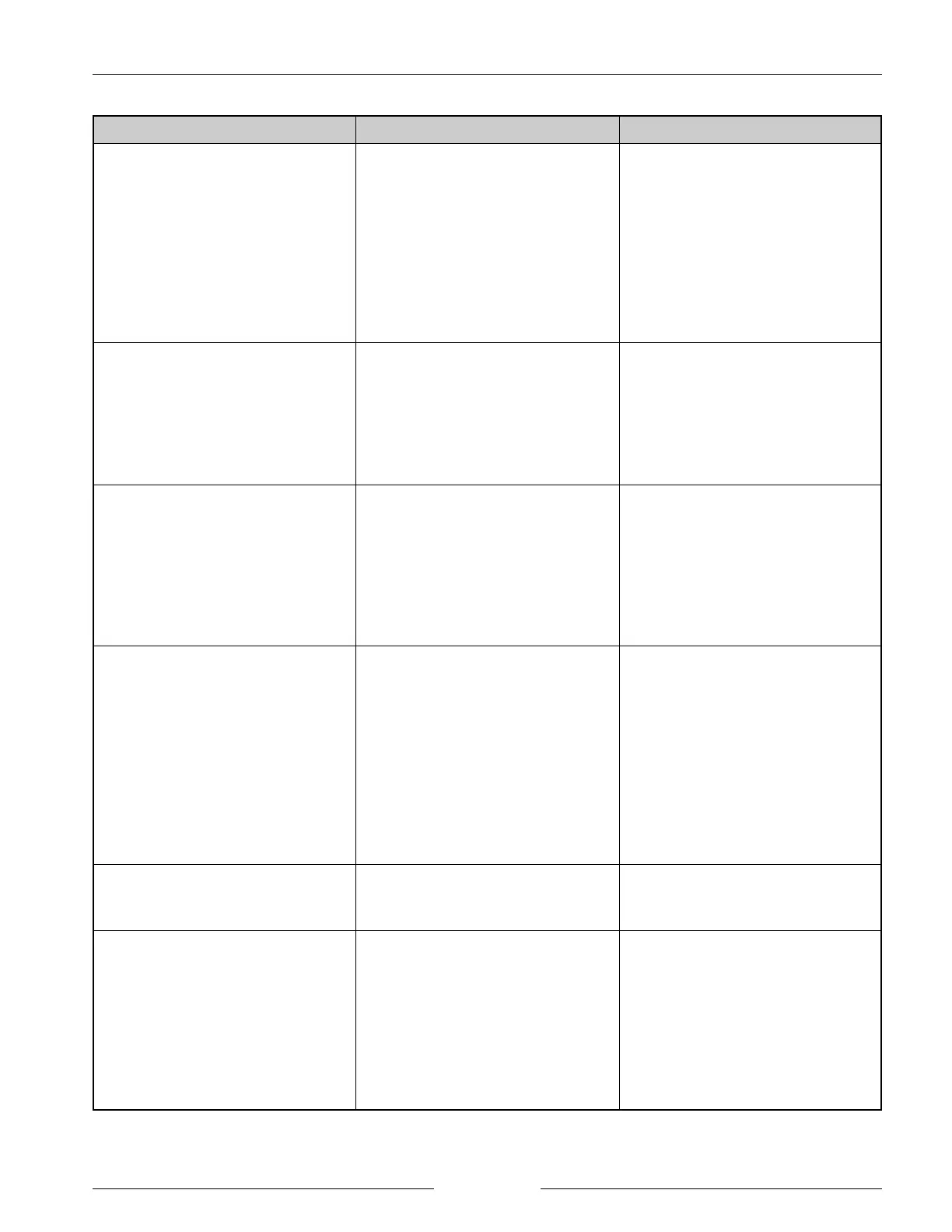

SECTION 6 - AIR SYSTEM SERVICE

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

page 6-5

Product buildup/accumulation in

air passage ways (high moisture

product).

1. Humid air conditions.

2. Moisture sensitive product.

3. Moisture condensation in the

tank.

4. Product left in tank too long.

1. Change to a different product.

2. A full tank reduces potential for

this problem.

3. Do not place product in tank

until time of use.

4. Do not place product in tank

until time to use.

Product buildup/ accumulation in

air passageways (high levels of

moisture in the air).

1. Humid air conditions.

2. Water in the fan housing at

start-up.

3. Moisture /condensation in

hoses at start-up.

1. Drain fan housing after a rain.

2. Run system without product to

dry lines.

3. Run system without product to

dry lines.

Seed damage. 1. Air velocity too high on short

(center) primary hoses.

2. Wrong meter roller for large

products.

3. Product too dry.

1. Even out primary hose length.

2. Use coarse or extra coarse

meter roller.

3. Use higher moisture content

product.

Hoses wearing out. 1. Air velocity too high

(see above).

2. Tight curves in hoses.

3. Hoses not being rotated.

4. Abrasive product.

1. (See above).

2. Reroute hoses for longer

bends.

3. Rotate hose seasonally for

longer life.

4. Change product or accept

wear.

Inaccurate seed placement (seed

tool not set properly).

1. Back to front depth difference.

2. Center to end depth difference.

1. Level seed tool back to front.

2. Level seed tool center to end.

Inaccurate seed placement -

product blowing out of ground.

1. Air velocity too high (see

above).

2. Insufficient seed depth

placement.

3. Air flow too concentrated.

4. Too slow travel speed.

1. (see above).

2. Increase seeding tool depth.

3. Use spreading opener.

4. Increase tool speed.

Loading...

Loading...