Safety Precautions

DANGER

When working on the vehicle, shut down the en-

gine, set the parking brake, and chock the tires.

Before working under the vehicle, always place

jack stands under the frame rails to ensure the

vehicle can not drop. Failure to follow these

steps could result in serious personal injury or

death.

Daily Pretrip Inspections and

Maintenance

Complete the following inspection and maintenance

procedures to ensure that vehicle components are in

good working condition before each trip. A driver who

is familiar with the vehicle and drives it regularly can

perform the daily inspections, then add the weekly

and monthly post-trip inspections as scheduled.

If the driver does not operate the vehicle on a con-

sistent basis, all daily, weekly, and monthly inspec-

tion and maintenance procedures should be per-

formed before the trip.

IMPORTANT: The pre- and post-trip checklists,

inspections, and maintenance procedures de-

tailed in this chapter are not all-inclusive.

Refer to other component and body manufactur-

ers’ instructions for specific inspection and

maintenance instructions, as well as local, state,

and federal guidelines.

NOTE: If any system or component does not

pass this inspection, it must be corrected before

operating the vehicle. Whenever equipment re-

quires adjustment, replacement, and/or repair,

see the New Cascadia Workshop Manual for

procedures and specifications.

Suspension and Slack Adjuster

Inspection

Walk around the vehicle and visually inspect suspen-

sion and slack adjuster components.

1.

Inspect the following suspension components for

signs of structural damage, cracks, or wear.

•

springs

•

spring hangers

•

shocks

•

suspension arms

•

suspension brackets

•

axle seats

•

bushings

2.

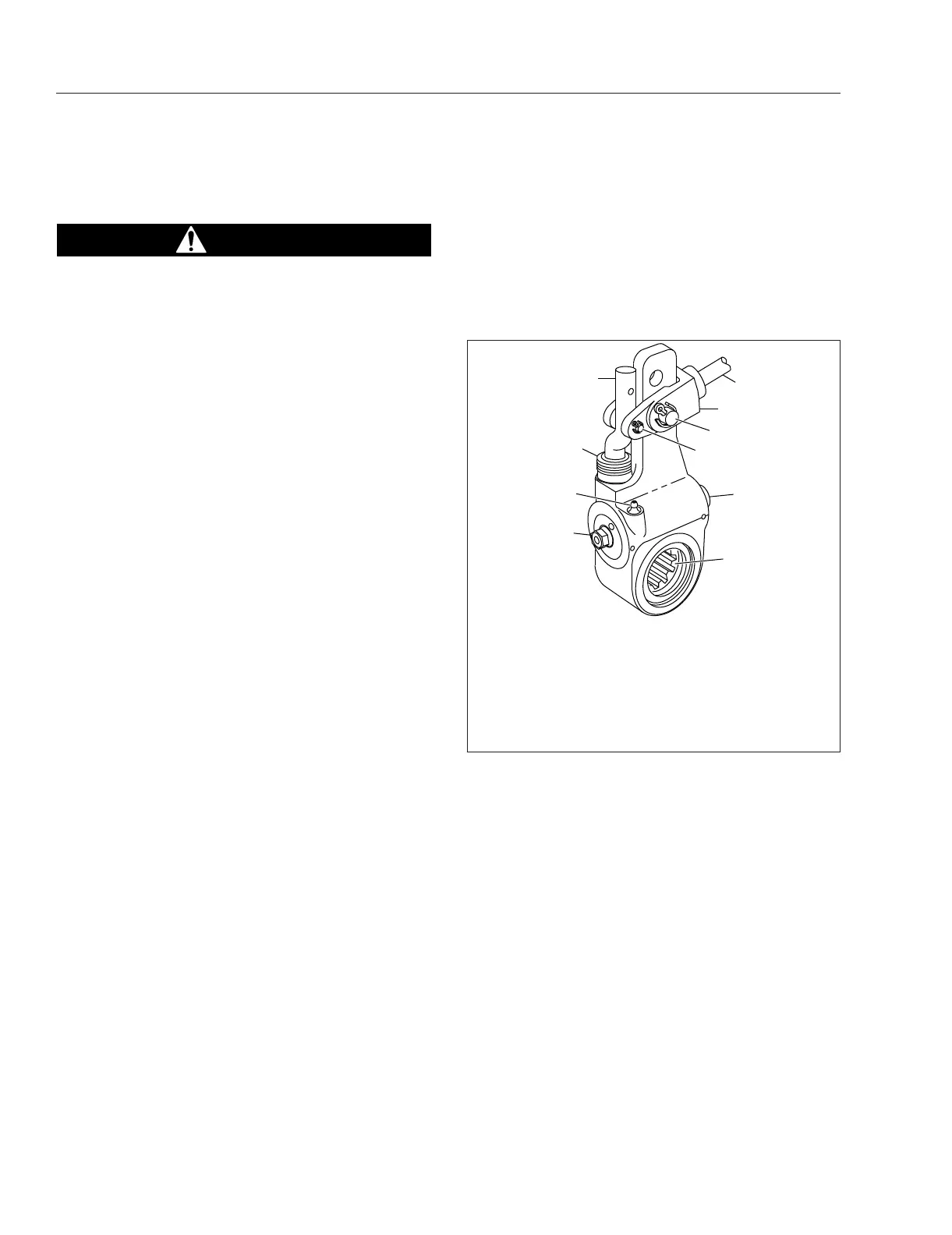

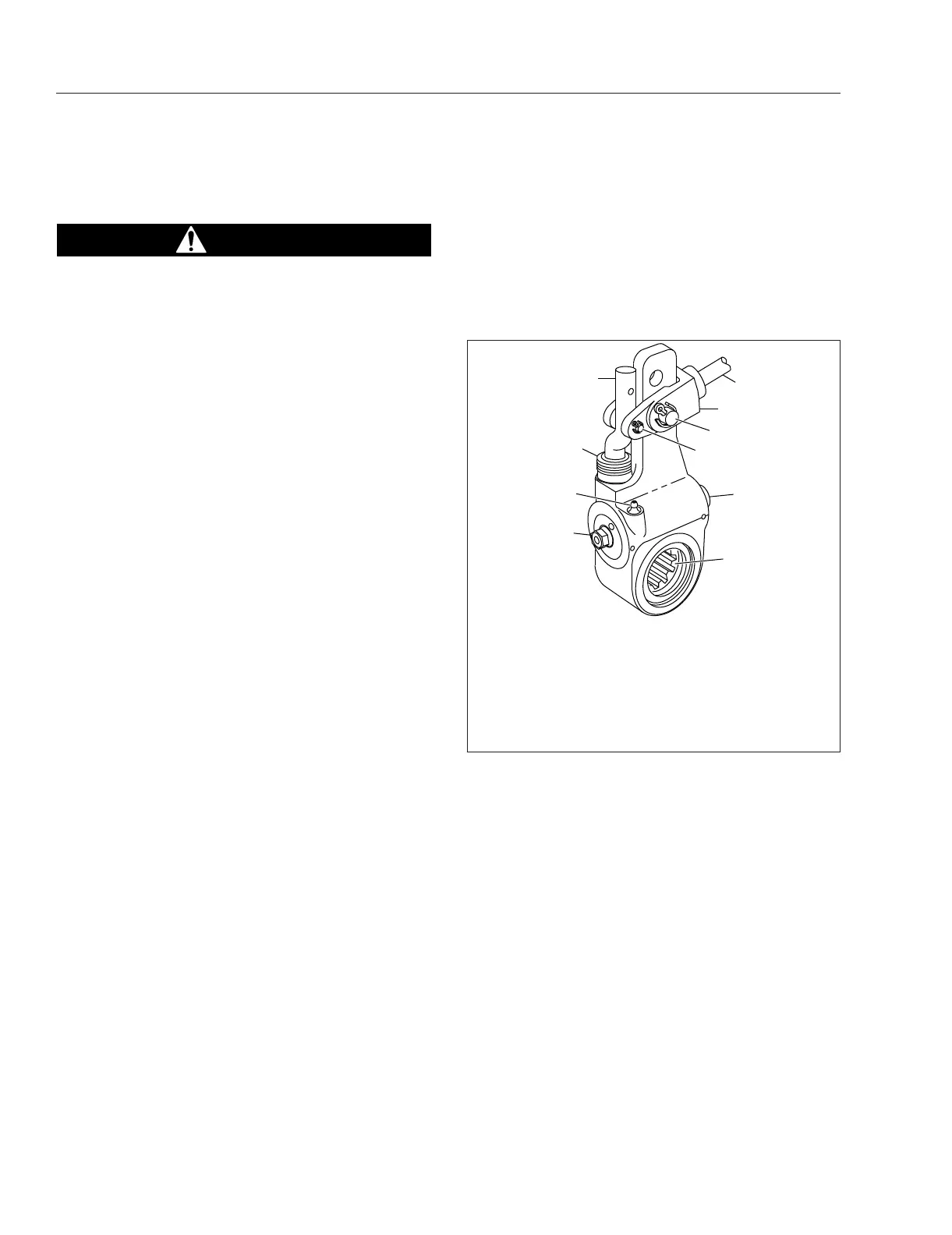

Inspect slack adjusters for signs of damage. See

Fig. 25.1, Fig. 25.2,orFig. 25.3.

•

Inspect slack adjuster boots, if equipped,

for cuts or tears.

•

Inspect anchor straps, if equipped, for

damage.

•

Look for worn clevis pins on brake cham-

ber pushrods.

•

Look for missing or damaged cotter pins

on the clevis pins.

•

Ensure chamber piston rods are in line

with the slack adjusters.

Wheel and Tire Inspection

Walk around the vehicle and visually inspect each

wheel and tire assembly.

f42139802/03/2017

1

2

3

4

5

6

7

8

10

9

1. 7/16-inch Adjusting

Nut

2. Grease Fitting

3. Boot

4. Link

5. Brake Chamber Piston

Rod

6. Clevis

7. ½-inch Clevis Pin

8. 1/4-inch Clevis Pin

9. Grease Relief

Opening

10. Slack Adjuster Spline

Fig. 25.1, Gunite Automatic Slack Adjuster

Pre- and Post-Trip Inspections and Maintenance

25.1

Loading...

Loading...