for inspection or testing purposes. These systems,

when fully charged contain fluid at high pressure.

Before disconnecting any hydraulic tubes, hoses

or fittings, be sure that the system is fully depres-

surized.

When servicing a vehicle, always wear eye pro-

tection and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing a Transmission system prob-

lem, it is important to follow approved procedures

where applicable. These procedures can be found in

the service information. Following these proce-

dures is very important to the safety of individuals

performing diagnostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If it does not, false diagnostic

DTC’s or error messages may occur. It is extremely

important that accurate shift lever position data be

available to the PCM. The accuracy of any DTC

found in memory is doubtful unless the Shift Lever

Test, performed on the DRBIIIt Scan Tool, passes

without failure.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the Transmission system

are intended to be serviced in assembly only. At-

tempting to remove or repair certain system sub-

components may result in personal injury and/or

improper system operation. Only those compo-

nents with approved repair and installation proce-

dures in the service information should be ser-

viced.

4.2.4 DRBIIIT SAFETY INFORMATION

WARNING: EXCEEDING THE LIMITS OF THE

DRBIIIT MULTIMETER IS DANGEROUS. IT

CAN EXPOSE YOU TO SERIOUS OR

POSSIBLY FATAL INJURY. CAREFULLY

READ AND UNDERSTAND THE CAUTIONS

AND THE SPECIFICATION LIMITS.

• Follow the vehicle manufacturer’s service speci-

fications at all times.

• Do not use the DRBIIIt if it has been damaged.

• Do not use the test leads if the insulation is

damaged or if metal is exposed.

• To avoid electrical shock, do not touch the test

leads, tips, or the circuit being tested.

• Choose the proper range and function for the

measurement. Do not try voltage or current

measurements that may exceed the rated capac-

ity.

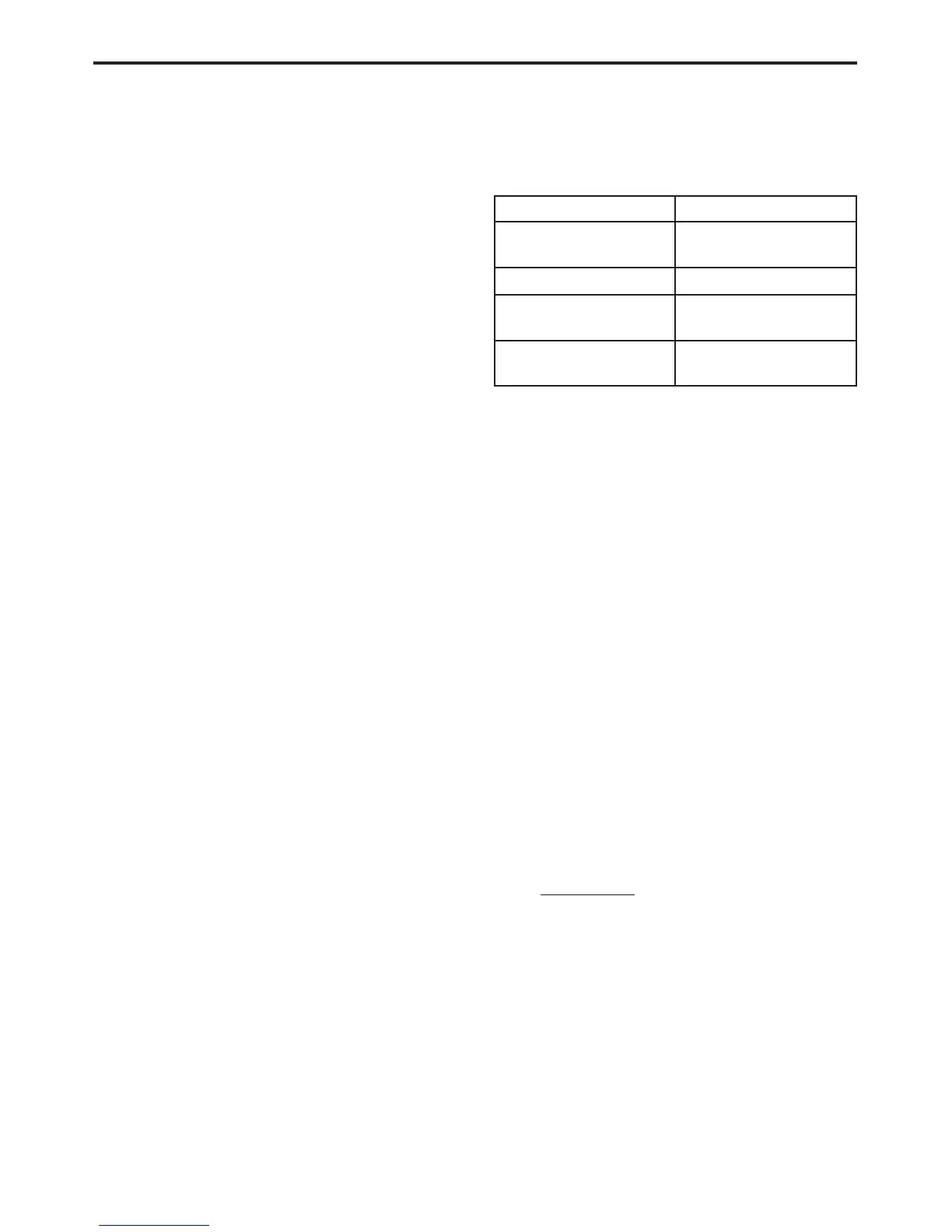

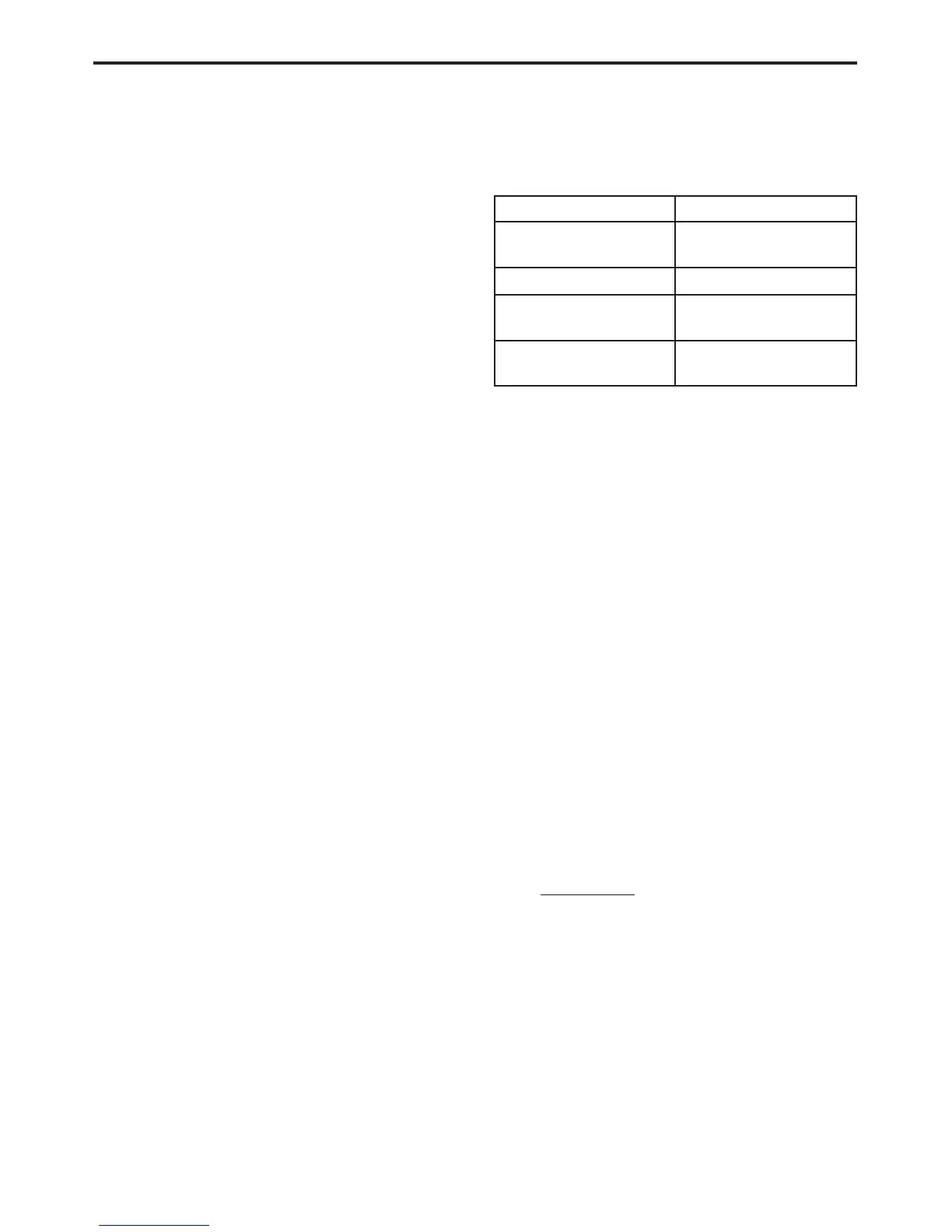

• Do not exceed the limits shown in the table.

FUNCTION INPUT LIMIT

Volts 0 - 500 volts peak AC

0 - 500 volts DC

Ohms (resistance)* 0 - 1.12 megohms

Frequency Measured

Frequency Generated

0-10kHz

Temperature -58 - 1100°F

-50 - 600°C

*Ohms cannot be measured if voltage is present.

Ohms can be measured only in a non-powered

circuit.

• Voltage between any terminal and ground must

not exceed 500v DC or 500v peak AC.

• Use caution when measuring voltage above 25v

DC or 25v AC.

• The circuit being tested must be protected by a

10A fuse or circuit breaker.

• Use the low current shunt to measure circuits up

to 10A. Use the high current clamp to measure

circuits exceeds 10A.

• When testing for the presence of voltage or

current, make sure the meter is functioning

correctly. Take a reading of a known voltage or

current before accepting a zero reading.

• When measuring current, connect the meter in

series with the load.

• Disconnect the live test lead before disconnect-

ing the common test lead.

• When using the meter function, keep the

DRBIIIt away from spark plug or coil wires to

avoid measuring error from outside interference.

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is “lock” position. Failure to do so

could damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually

cause it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

21

GENERAL INFORMATION

Loading...

Loading...