ENTRON Controls, LLC. • 700120S • Page 105

8.4.2 SETTING UP CURRENT REGULATOR – BOARDS WITH PROMS

BEFORE FIRMWARE VERSION 619016-001R

(for archival purpose only)

1. Setup must be done in SPOT mode (

S.E.S.E.

S.E.S.E.

S.E.=

0000

0000

00). If doing seam welding, re-program parameter

S.E.S.E.

S.E.S.E.

S.E. after setup. The control must be initiated using a FS3 initiation switch connected between

TS1-FS3 and TS1-GND. If the machine does not have initiations using this terminal,

temporarily connect a switch to FS3.

2. Using schedule 01, make sample welds in NON-CONSTANT CURRENT mode (

C.rC.r

C.rC.r

C.r

..

..

.=

0000

0000

00)

to determine the proper welding transformer tap switch setting. PERCENT CURRENT

should be between 70% and 80%* and WELD time should be the recommended number of

cycles for material being welded.

*

In order for the control to adapt to changing conditions, it must be able to adjust current. If weld is made

around 75%, the control can move up to 99% or down to 20% if necessary to maintain current constant

when the control is in CONSTANT CURRENT mode.

DO NOT USE SCHEDULE 00 IN STEP 2!

3. Switch to PROGRAM mode.

a) Select EXTENDED FUNCTION

C.rC.r

C.rC.r

C.r

..

..

., program

1010

1010

10, and press ENTER.

b) Select EXTENDED FUNCTION

rr

rr

r

.A..A.

.A..A.

.A., program

00.9900.99

00.9900.99

00.99, and press ENTER.

c) Select EXTENDED FUNCTION

C.A.C.A.

C.A.C.A.

C.A., program

0404

0404

04, and press ENTER. This presets

schedule 00 with specific setup parameters, including 30 cycles of SQUEEZE time and

VALVE 1 output.

d) You may change SQUEEZE time to match machine requirements, and press ENTER.

e) You may change VALVE Output to match machine requirements, and press ENTER.

DO NOT MAKE ANY OTHER CHANGES!

4. Switch to OPERATE mode. At this time, the DATA display

should flash

S.e.t.S.e.t.

S.e.t.S.e.t.

S.e.t.

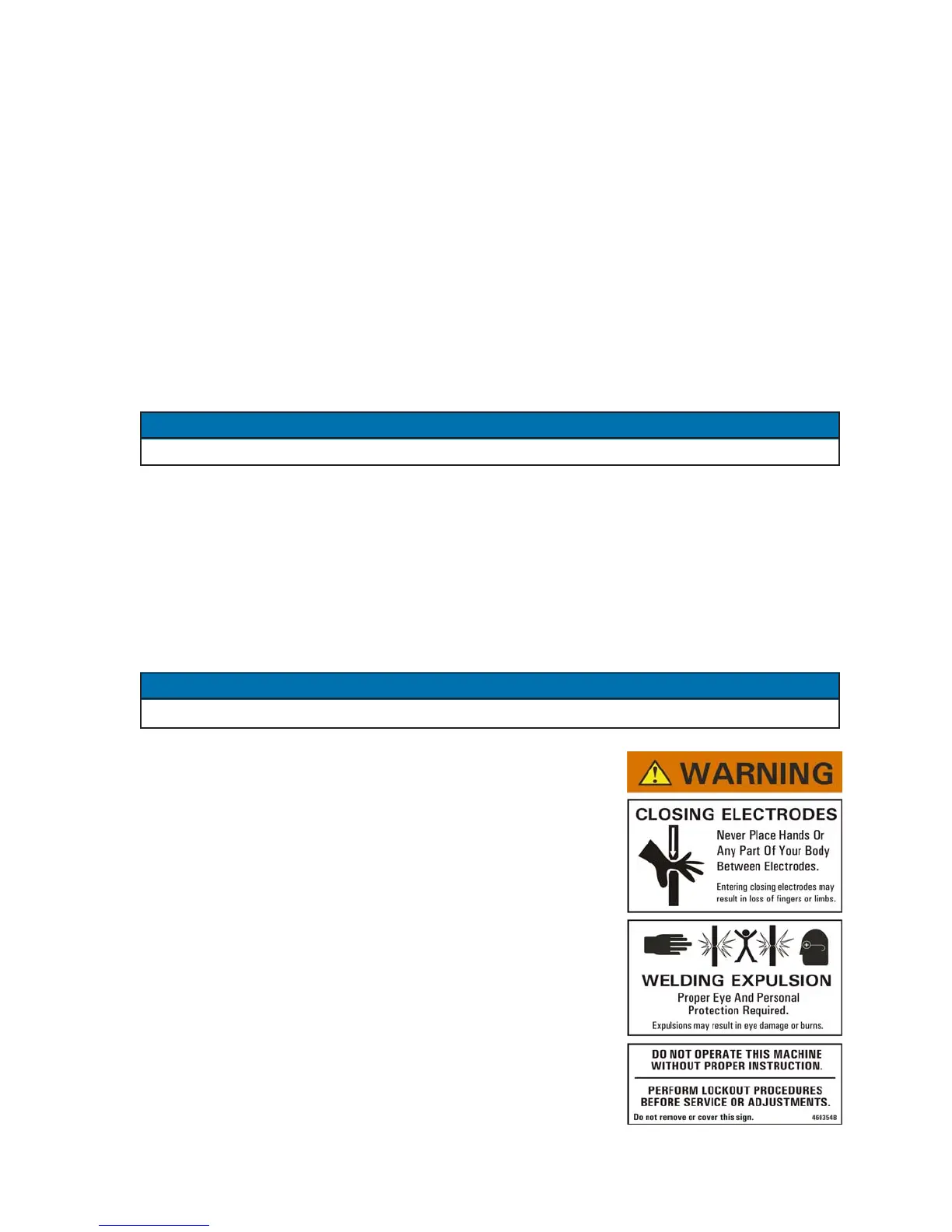

5. Using the same material already welded **, insert it between

the machine electrodes, initiate a weld sequence and hold

the initiation switch closed. The machine electrodes will

close and the control will sequence through a preset test

schedule. When it is finished, it will display ERROR CODE

0505

0505

05.

** While in setup, the control makes multiple welds at 99% for 4

cycles. If the part being welded cannot support weld times of 4

cycles at 99% without expulsion or distortion, the parameters

measured may not provide correct setup data. In this case, run the

setup with no material between the electrodes.

6. Release the initiation switch. The control is now set up and

ready to operate. PERCENT CURRENT must be re-

programmed now as a four-digit number (example: 80% =

00800080

00800080

0080).

NOTICE

NOTICE

Loading...

Loading...