ENTRON Controls, LLC. • 700120S • Page 9

1.0 GENERAL DESCRIPTION

The EN1000/EN1001 Control is a microprocessor based welding control. It can perform Upslope,

Downslope, Quench, Temper, Pulsation, Seam, and Spot, all of which can be combined to

provide for any possible welding schedule imaginable. It can store as many as 11 base parameters

in each of 50 unique schedules. These are held in non-volatile memory for storage. In addition,

schedules can be chained together to provide more complex welding sequences. Despite the

seemingly complicated possible welding schedules, both the EN1000 and EN1001 Controls

are simple to program and operate.

The control provides accurate, predetermined execution of welding schedules for specific

numbers of cycles upon an external command. Initiation commands can be given by the closure

of a normally-open switch installed as part of the welding machine. The initiation switches

need not remain closed for the duration of the weld, but must be opened after the welding

interval is completed in order to re-initiate the control. After a weld has been started, the control

cannot be re-initiated until the previous sequence is completed.

The EN1000 and EN1001 Controls are designed to operate in conjunction with a welding

transformer rated for the 60 Hz or 50 Hz output frequency. These controls can be used either on

60 Hz or 50 Hz, without any additional settings or changing parameters. These controls are not

designed to operate with mid-frequency transformers with 500 Hz to 2000 Hz operating

frequency rating.

The EN1001 differs from EN1000 as it has a Constant Current mode of operation, see Section

5.4.15 and Section 8.0.

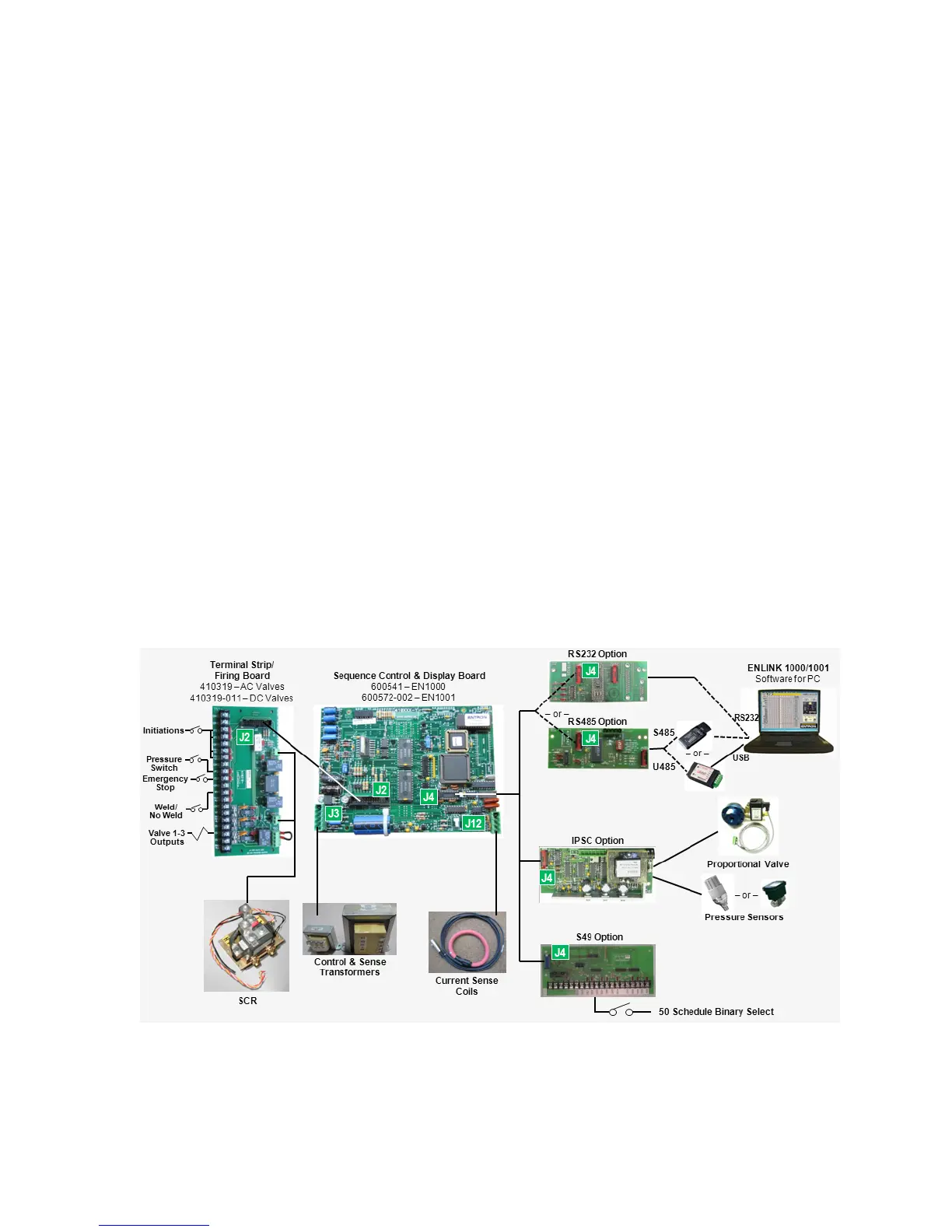

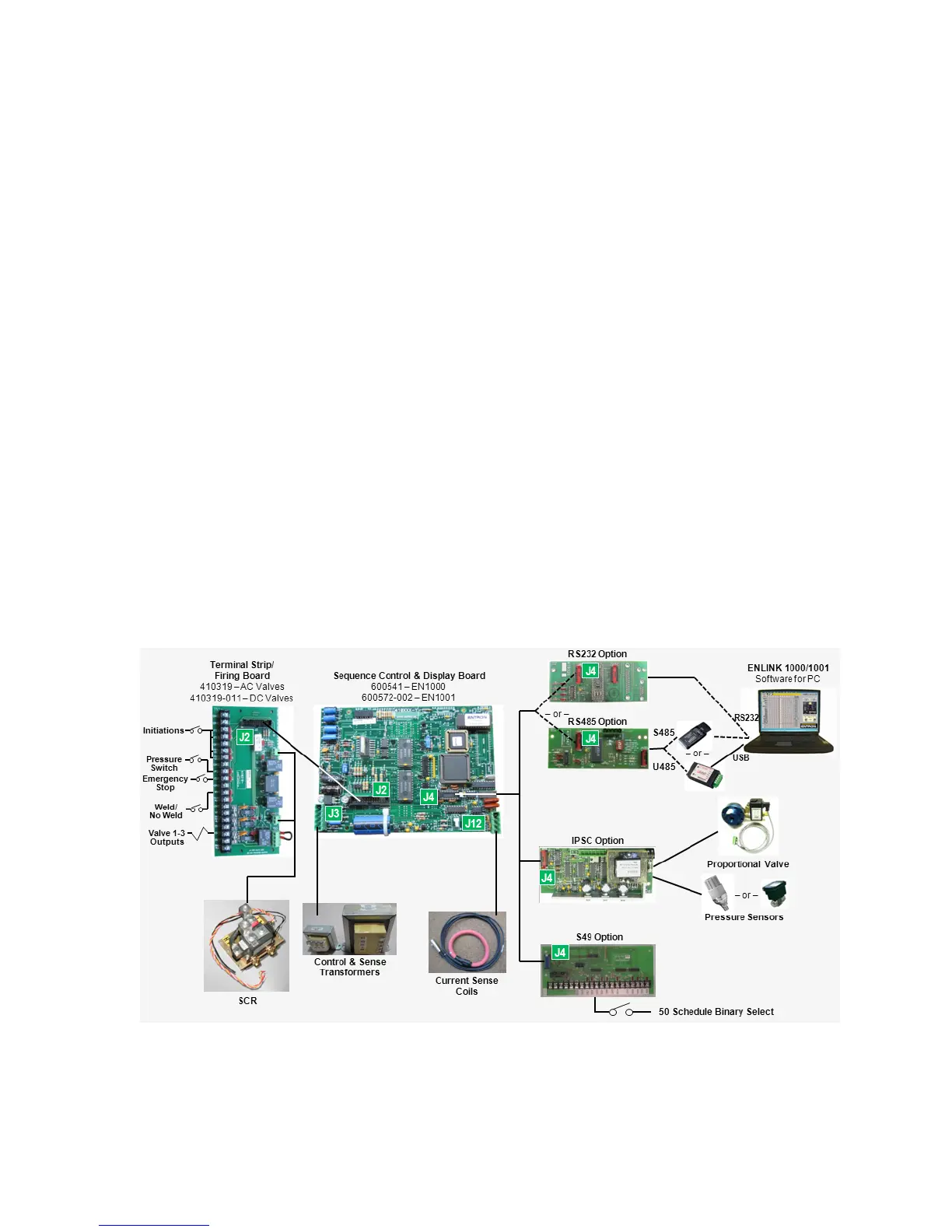

Figure 1-1. EN1000/EN1001 System

Loading...

Loading...