ENTRON Controls, LLC. • 700120S • Page 113

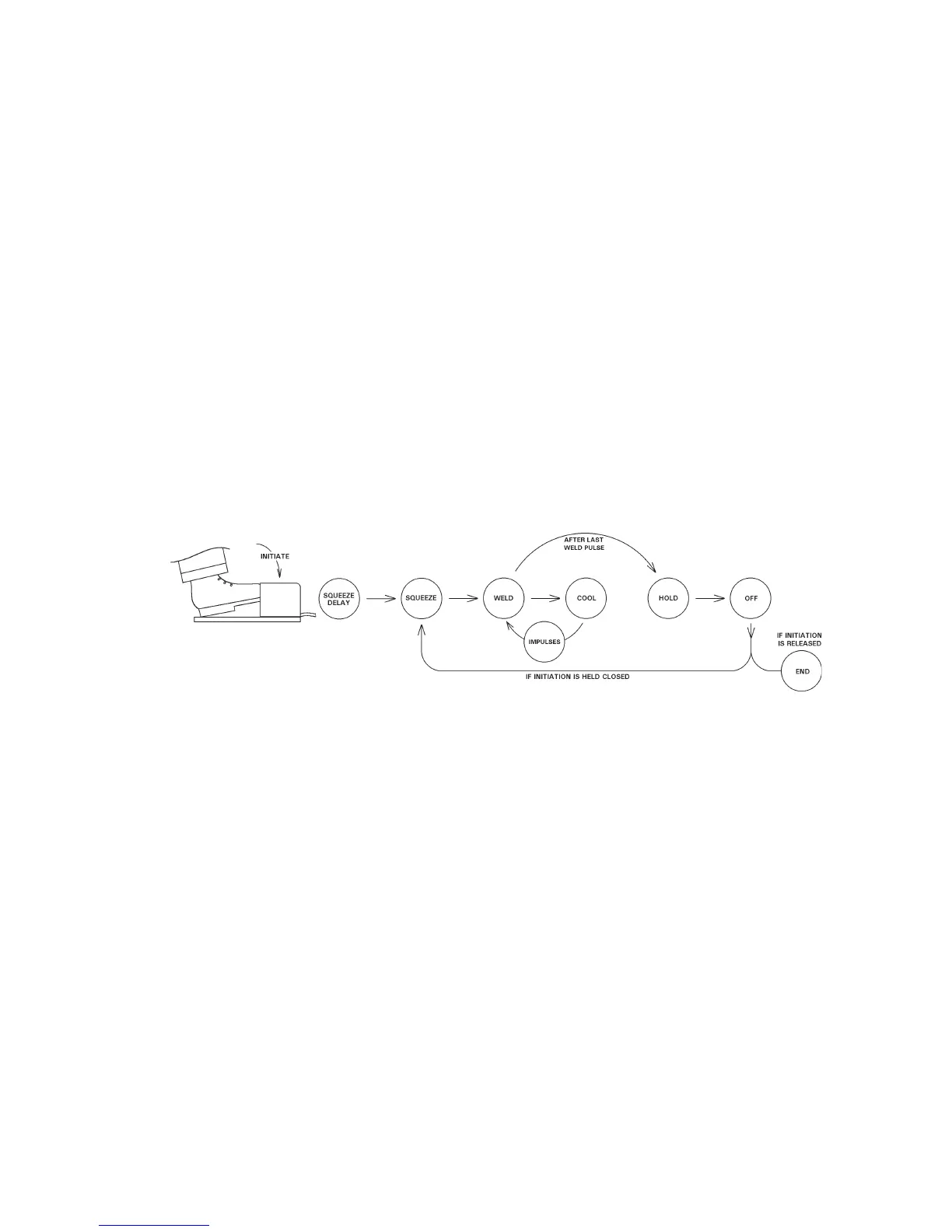

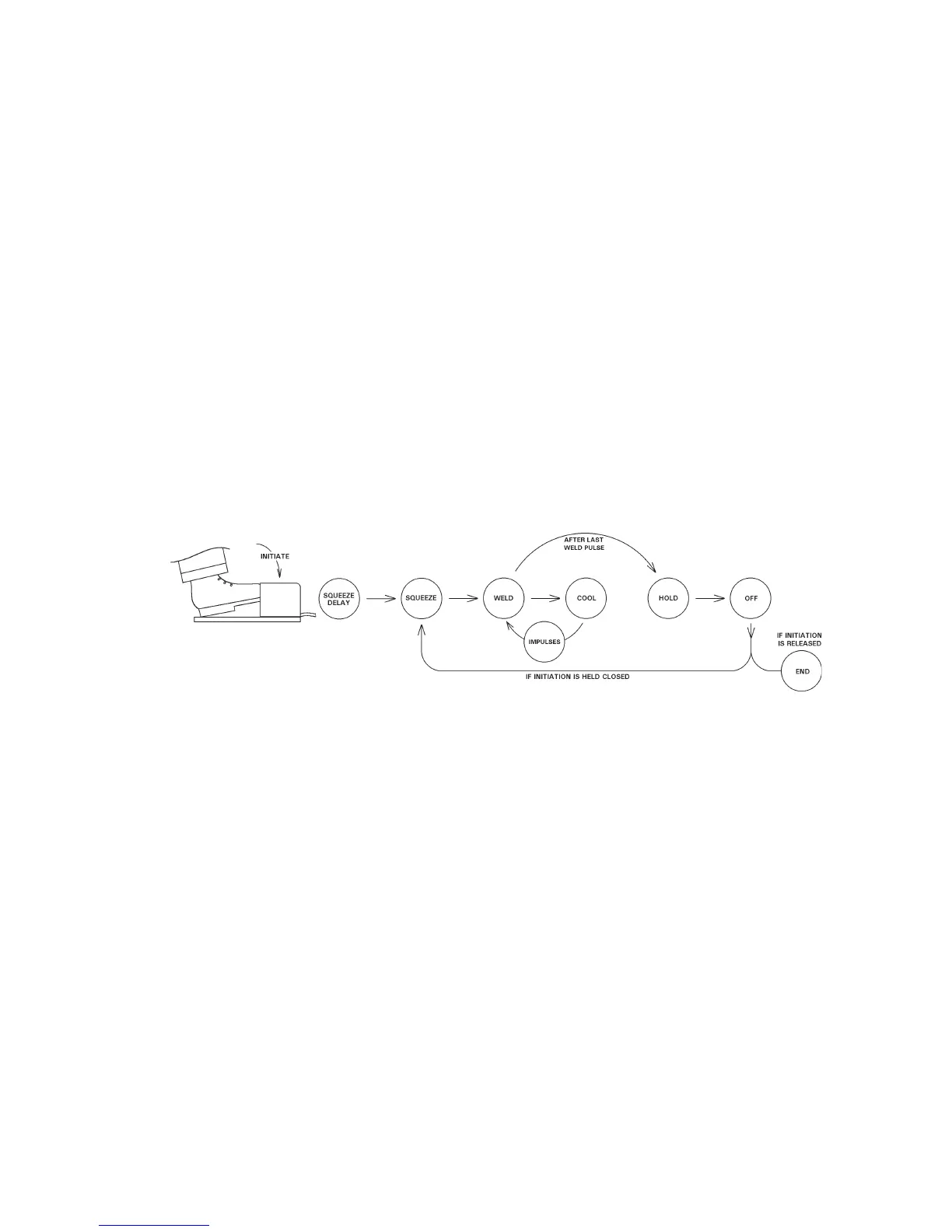

9.4 SQUEEZE DELAY APPLICATION

Some applications require the welder arms be opened wide to allow the electrodes to access

areas to be welded. SQUEEZE DELAY was designed for use with welding guns and stationary

machines incorporating standard air cylinders and valves without retraction features. The

additional time provided by the SQUEEZE DELAY will allow the electrodes to travel a greater

distance and simulate the retraction function. SQUEEZE DELAY is only active in the first

schedule in a REPEAT sequence.

9.4.1 SQUEEZE DELAY OPERATION

Setting the control for SQUEEZE DELAY will provide additional time before the programmed

SQUEEZE time in all schedules. The SQUEEZE indicator LED on the Control Panel will dim

slightly during the programmed SQUEEZE DELAY time. SQUEEZE DELAY time occurs only

during the first SQUEEZE of a series of repeated welding sequences (REPEAT mode).

SQUEEZE DELAY will be present in all schedules even if no other data has been entered.

SQUEEZE DELAY is not intended for use with SEAM modes of operation. If not required, set

S.d.S.d.

S.d.S.d.

S.d. to

0000

0000

00.

Figure 9-11. SQUEEZE DELAY operation

9.4.2 SQUEEZE DELAY PROGRAMMING

1. Press SELECT push button repeatedly until FUNCTION indicator LED has advanced past

SLOPE COUNT to enter data in EXTENDED FUNCTIONS (

EFEF

EFEF

EF).

2. Move through the EXTENDED FUNCTIONS until

S.d.S.d.

S.d.S.d.

S.d. appears in SCHEDULE display.

3. Press PROGRAM/OPERATE push button to place the control in PROGRAM mode.

4. Press DATA push buttons until desired SQUEEZE DELAY time (time=number of cycles) is

displayed in DATA display.

5. Press ENTER push button to store the desired data.

6. Select and enter CYCLE MODE=

0101

0101

01 (REPEAT).

7. Adjust SQUEEZE and OFF times to allow the electrodes to open only a short distance

between repeated welding sequences.

8. Press PROGRAM/OPERATE push button to put the control in OPERATE mode.

Loading...

Loading...