Page 158 • 700120S • ENTRON Controls, LLC.

APPENDIX F EN1003 THREE PHASE DC CONTROLS

Wiring Diagrams

EN1003 Controls in “L” & “H” Cabinets – 421291 Series

EN1003 Controls in “T/D” Cabinets – 421310 Series

Three Phase DC applications are frequently characterized by:

1. High weld current requirements typically with poor secondary power factor

configurations.

2. One common core transformer or three individual transformers connected three phase.

3. Secondary diode configurations of either half or full wave rectification.

Typical jobs that require DC weld controls are those that require either large secondary currents

or, by design, have high power losses caused by ferrous metals in the throat of the welder, such

as parts of the machine and/or welded parts. Because of the DC current, rather than AC, in the

secondary path, inductive losses are cut to a minimum and only resistive losses are of a concern.

This Appendix is to be used in conjunction with Wiring Diagram 421291 (“L” & “H” Cabinets)

or 421310 (“T/D” Cabinets) and this manual, which is applicable to all models in the EN1003

Series. However, some sections of this manual apply only to EN1000 and EN1001 Series Single

Phase Controls and should be disregarded for EN1003 Controls.

Sections to be disregared are as follows:

Section 1.1 (Standard Features) – Notice concerning 60 Hz or 50 Hz operation

Sections 3.1, 3.2, 3.3, 3.4, 3.5 (Installation and Mounting Diagrams)

Section 3.6 (Welding Tranformer Primary Wiring)

Section 3.7 (External SCR Contactor Wiring)

Section 4.1 (Operating Voltage)

Section 4.2 (Fusing)

Section 4.3.3 (Terminal Strip TS1 Inside the Cabinet)

Information contained in this Appendix and on Wiring Diagrams replaces the information

contained in these sections.

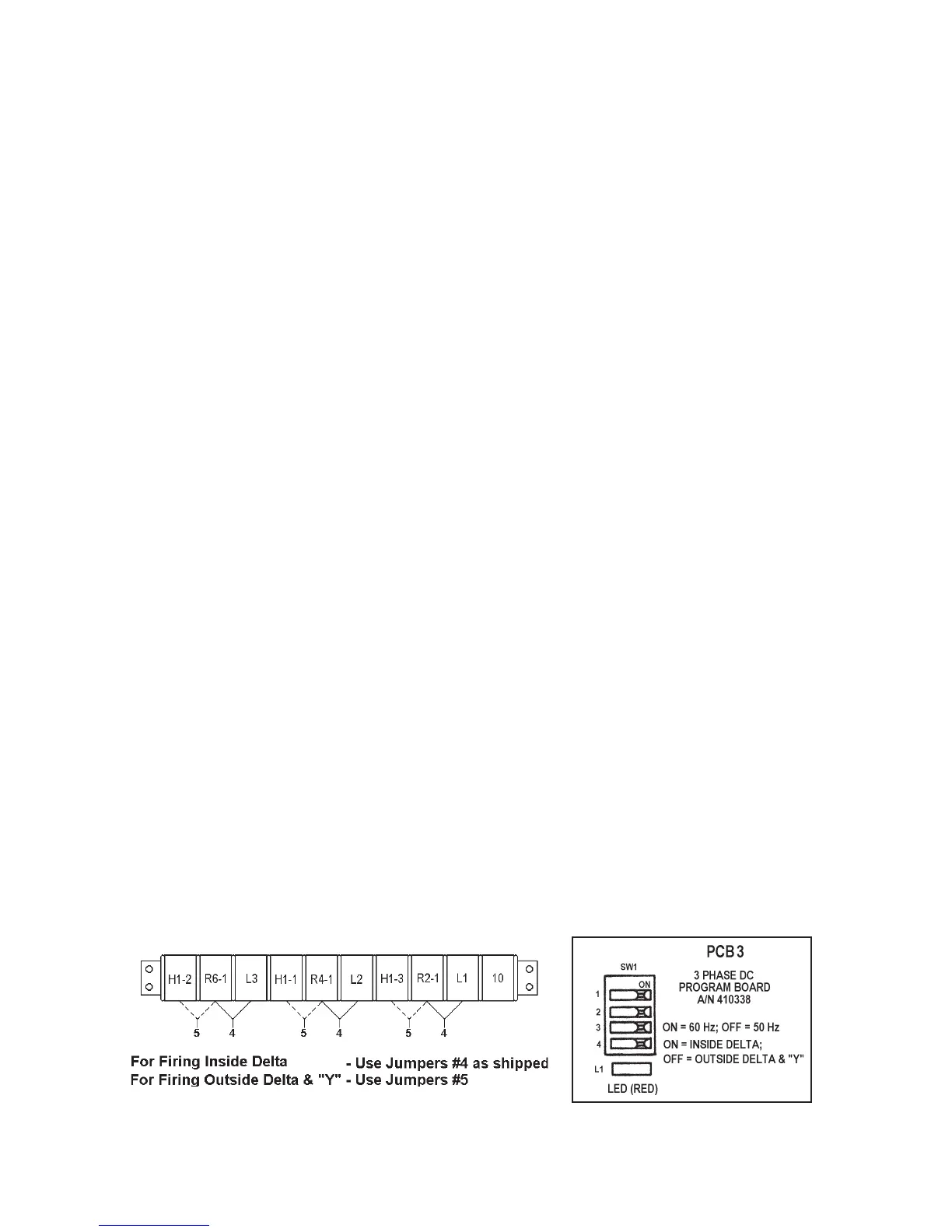

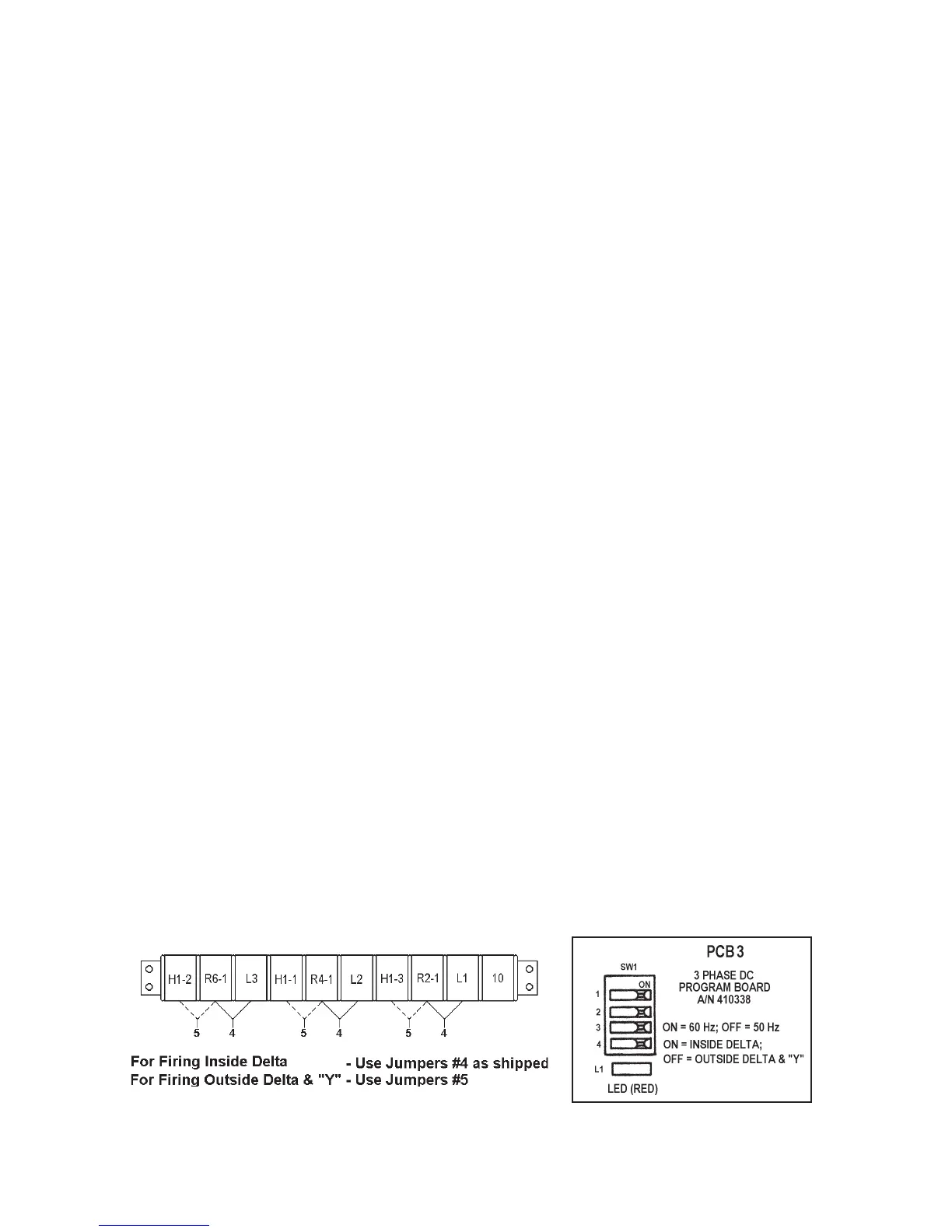

All EN1003 models fire three welding contactors, controlled by one digital phase shift heat

control setting, and may be connected to the welding transformers in an outside delta, inside

delta, or “Y” configuration (see Figures F-6 and F-7). Jumpers on TS10 Terminal Strip (Figure

F-1) and SW1 position #4 (Figure F-2) on PCB3 (A/N 410338) must be set accordingly; also

see Views “B”, “C”, “D” and Note 2 on Wiring Diagrams. Transformer secondaries may be

connected for half wave or full wave rectification.

Figure F-1. TS10 connections Figure F-2. PCB3 SW1 and L1

Loading...

Loading...