Page 162 • 700120S • ENTRON Controls, LLC.

APPENDIX H IMU MOUNTING OPTIONS

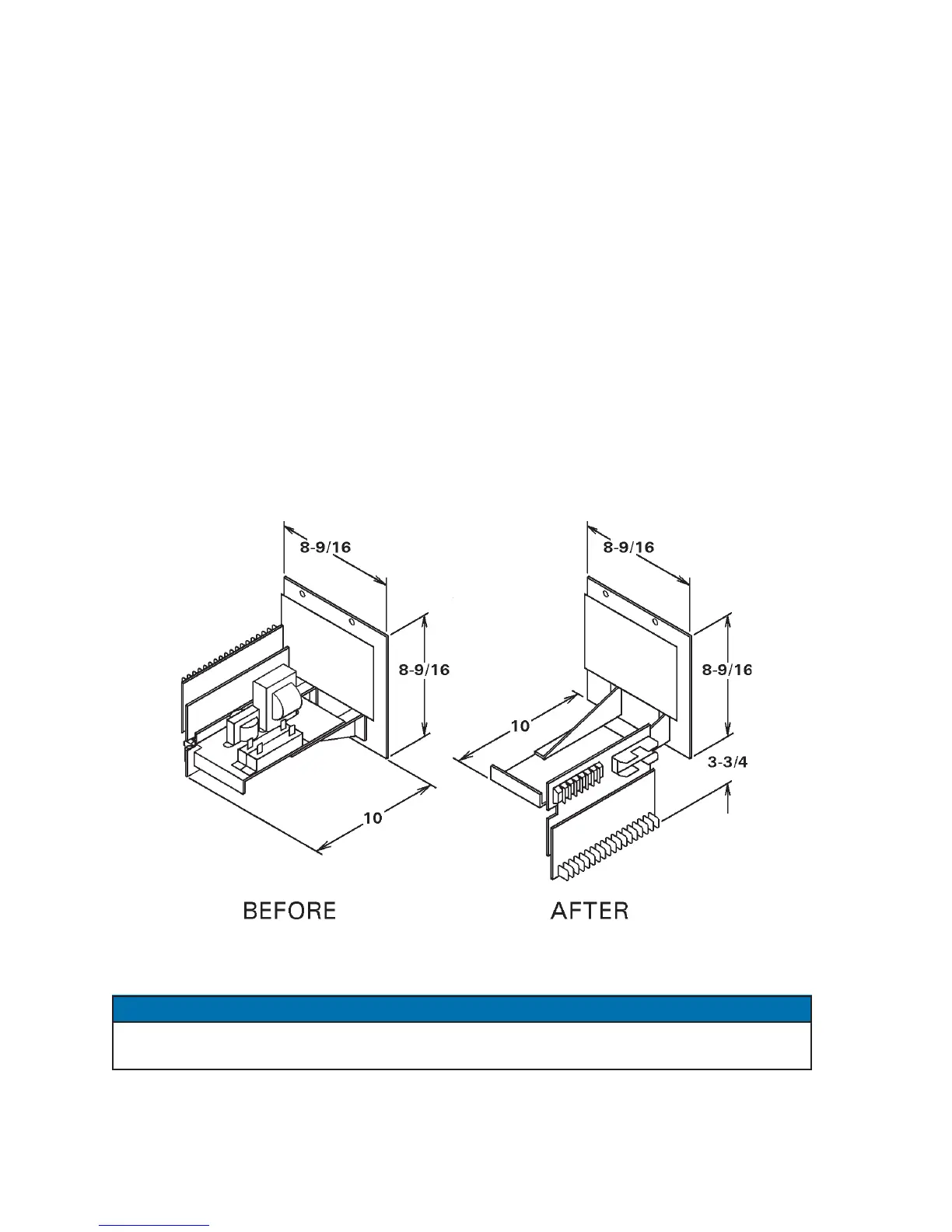

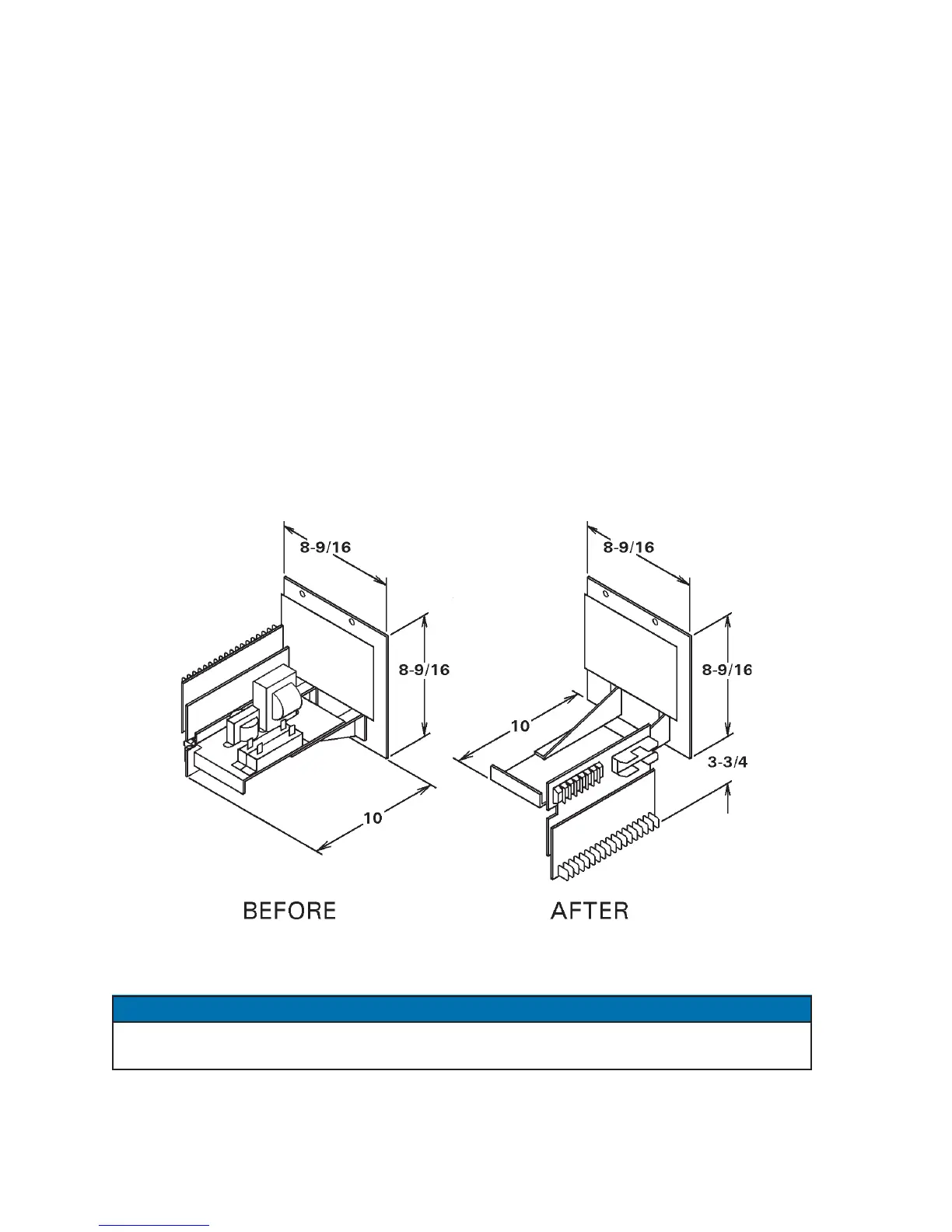

The Integrated Modular Unit (IMU) series of Weld Controls are designed for use in retrofit

situations or in new/custom designs. Customers are free to place one or more of these units in

existing enclosures or new designs as requirements demand. To make the IMU even more

flexible, the rear chassis can be rotated 180

EE

EE

E. If the IMU as supplied cannot be oriented so

that the Terminal Strip/Firing PCB, Voltage Programming Terminal Strip and fuse holder can

be accessed directly, the chassis can be inverted (turned upside down) to provide access as

shown in Figure H-1. Before installing the IMU in an enclosure, determine whether or not the

chassis needs to be flipped. If rotation of the chassis is required, follow the instructions below.

1. Unplug the J2, J3, Weld light and Power light terminal connections, mark the wires for

reconnection later.

2. Remove and retain the four 6-32 nuts and split lock washers that attach the IMU mounting

brackets to the Dial Plate.

3. Rotate the IMU chassis 180E on its long axis and remount the brackets to the studs on the

Dial Plate (see Figure H-1).

4. Extend the J2 and Power light harnesses from their tied-back positions and reconnect all

the connections removed above.

Figure H-1. IMU rotation option

The standard IMU configuration on the left does not require as much clearance space below

the Dial Plate mounting as the new configuration on the right.

NOTICE

Loading...

Loading...