Page 84 • 700120S • ENTRON Controls, LLC.

In order to determine where control will wait in CYCLE MODE

0505

0505

05, corresponding SCHEDULE

parameter must be programmed to 99. The control will wait on SQUEEZE if SQUEEZE is

programmed to 99, or WELD/COOL if IMPULSES is 99, or HOLD if HOLD is 99.

The following sequence illustrates an example of how to use this CYCLE MODE.

After welding sequence is started with FS3, the control will execute a chain on schedule 00,

wait for re-initiation on schedule 01, execute chain on schedule 02 and then it will weld

indefinitely on schedule 03 (because CYCLE MODE=

0505

0505

05 and IMPULSES=

9999

9999

99). It will continue

to weld until one of two conditions occur: 1) Emergency Stop or Temperature Limit Switch is

open causing sequence to be stopped or 2) FS7 or FS11 is activated causing the control to jump

to schedule 10 or 20, respectively, and execute whatever sequence is programmed there. In this

case for schedule 03, SQUEEZE time must be less than 99 cycles, otherwise the control will

wait on SQUEEZE. In order to wait on HOLD, both SQUEEZE and IMPULSES must not be

programmed to 99.

Use WAIT-HERE function (CYCLE MODE=

0505

0505

05) with full understanding

of machine and control operation. Enabling of

b.E.b.E.

b.E.b.E.

b.E.=

0505

0505

05 has been added to help

ensure this operation is really required.

6.3 SLOPE MODES

The EN1000/EN1001 Series Controls offer UPSLOPE and DOWNSLOPE as standard features

for applications that require their use.

UPSLOPE/DOWNSLOPE function provides a means of gradually increasing or decreasing

weld current. How gradual the increase or decrease occurs is determined by the SLOPE bottom

current and the number of SLOPE cycles programmed in SLOPE COUNT. The number

programmed into SLOPE COUNT will determine the rate at which the control will reach the

programmed weld current. SLOPE COUNT is programmable from 01 to 99 (in ms at 1000 Hz).

When SLOPE MODE is used, its function is to change current gradually. The UPSLOPE mode

causes current to start from a low level and increase for a predetermined number of cycles.

When DOWNSLOPE is in use, the reverse is true. Current will start to decrease to low level for

a predetermined number of cycles.

The number of SLOPE cycles is automatically added to the number of WELD cycles. If 14

cycles of UPSLOPE are programmed in SLOPE COUNT, for SLOPE MODE

0101

0101

01 or

0202

0202

02, and the

number of WELD cycles is 21, the total amount of WELD time is 35 cycles.

6.2.6 WAIT-HERE – CYCLE MODE=

0505

0505

05 (cont.)

CAUTION

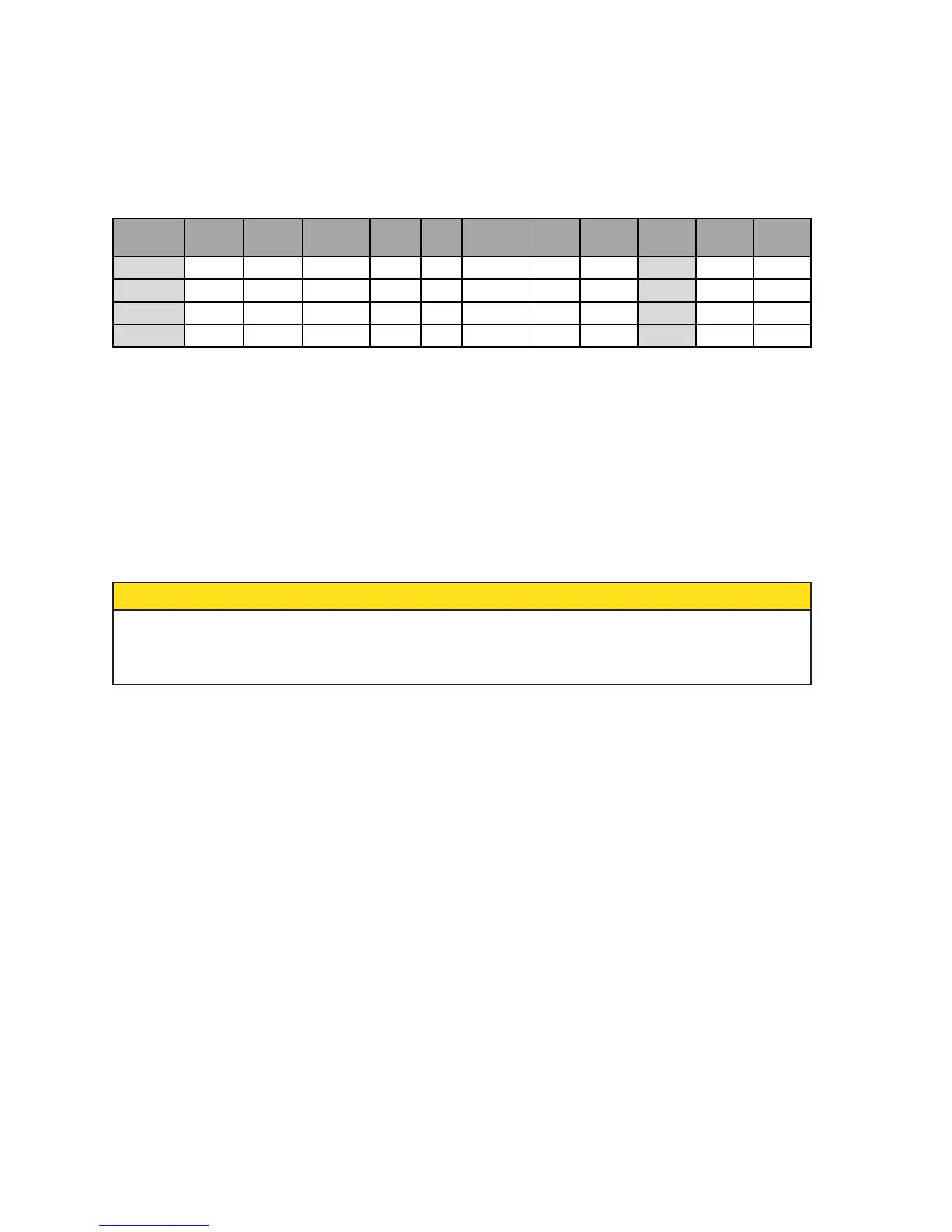

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

00 30 00 00 00 00 01 00 01 02 00 00

01 20 00 00 10 00 01 00 03 04 00 00

02 30 00 00 00 00 01 00 03 02 00 00

03 10 20 60 10 00 99 06 07 05 00 00

Loading...

Loading...