ENTRON Controls, LLC. • 700120S • Page 123

9.7 PROCESS OUTPUT

2626

2626

26

HOLD PART IN WELDER IF CURRENT OUT OF LIMIT WINDOW

This PROCESS OUTPUT requires the use of EN1001 Control Board Assembly No. 600572

with PROM firmware version 619016-002C or later. See Section 4.7 for information about

Isolation Contactors and Section 8.3.2 for programming HIGH and LOW CURRENT limits.

When

PP

PP

P

.O..O.

.O..O.

.O.=

2626

2626

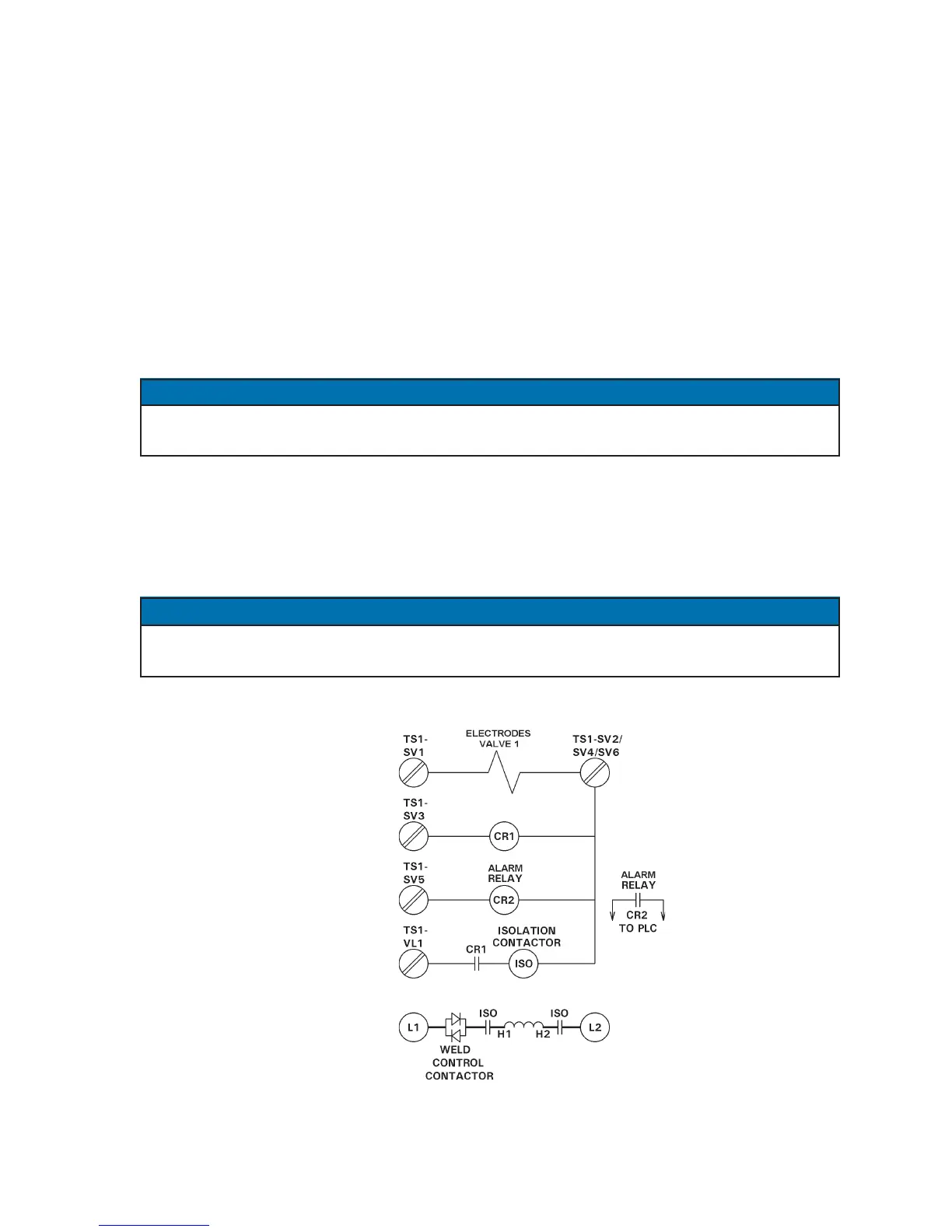

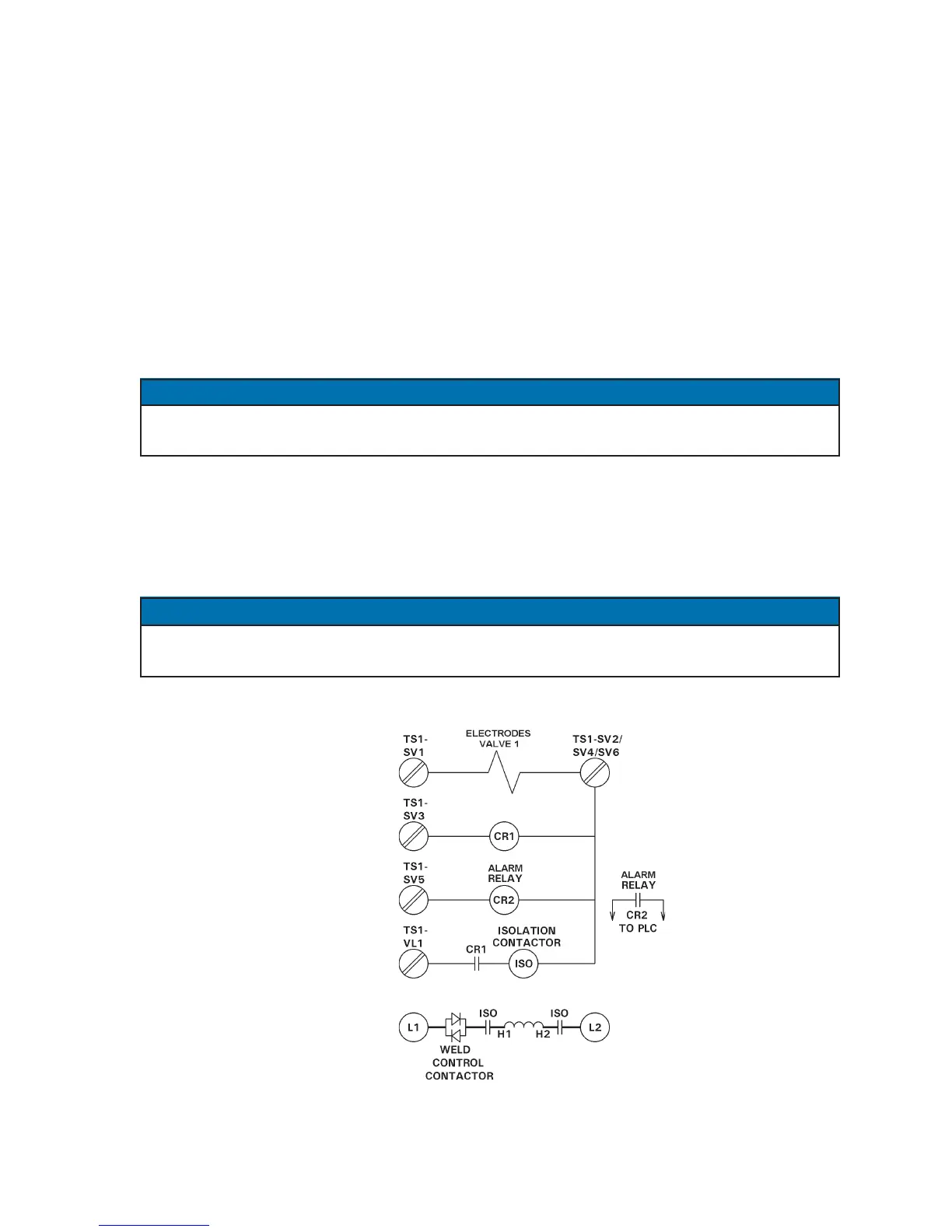

26, the weld control (when wired to the machine as shown in Figure 9-17) will hold

the part just previously welded, between the electrodes, if the measured current is not between

the programmed HIGH/LOW limit window. The valve assignment must be as follows:

Valve 1 TS1-SV1 Connects to Valve 1 for Electrodes

Valve 2 TS1-SV3 Connects to CR1 which drives Magnetic Isolation Contactor

Valve 3 TS1-SV5 Connects to Alarm Output CR2

On weld controls with a PROGRAM LOCKOUT key switch, the key must be rotated and

error cleared before the part can be removed from the welder.

9.7.1 VALVE 1 (Welding Head Solenoid Output for Electrodes)

Program desired schedule using Valve 1 for SQUEEZE, WELD, and HOLD times (set VALVE

MODE=

0303

0303

03).

This valve will stay on after the sequence is complete if current is out of programmed HIGH/

LO limit window. If current is within limit window, the valve will turn off at end of HOLD.

Figure 9-17. PROCESS OUTPUT

2626

2626

26 wiring

NOTICE

NOTICE

VALVE 1

VALVE 2

VALVE 3

Loading...

Loading...