ENTRON Controls, LLC. • 700120S • Page 99

8.2.1 SECONDARY PRESET-RANGE COMPENSATION OR MONITORING

MODE WITH ROGOWSKI COIL

In these modes, a learning-type setup process is not required. However,

rr

rr

r

.A..A.

.A..A.

.A. must be programmed

for the desired CURRENT range in which the machine will operate. Available values of

rr

rr

r

.A..A.

.A..A.

.A. are

shown in Table 8-1. If the desired range of

rr

rr

r

.A..A.

.A..A.

.A. is far below or far above operating range,

current overshooting or poor compensation will result.

COMPENSATION

With

C.rC.r

C.rC.r

C.r

..

..

.=

3232

3232

32, the control will operate in SECONDARY PRESET-RANGE COMPENSATION

mode with Rogowski Coil. When the control operates in this COMPENSATION mode, the

value of PERCENT CURRENT setting in the weld schedules should be input as the required

secondary output current in [kA].

MONITORING

With

C.rC.r

C.rC.r

C.r

..

..

.=

3333

3333

33, the control will operate in SECONDARY PRESET-RANGE MONITORING mode

with Rogowski Coil. When the control operates in this MONITORING mode, the control will

only display the weld current after a weld but will not compensate the current error. The value

of PERCENT CURRENT setting in the weld schedules should be input as the percentage [%]

of maximum current output of the control.

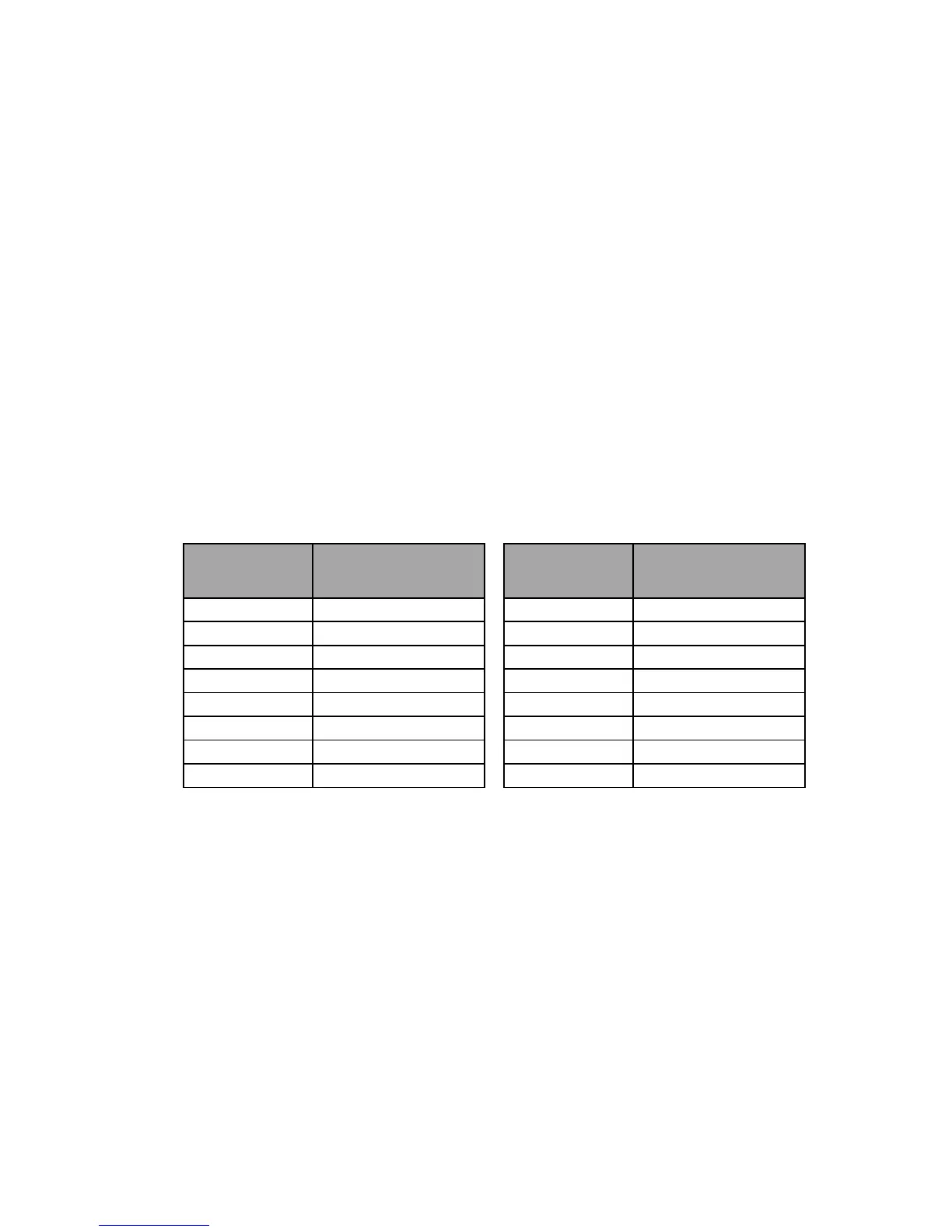

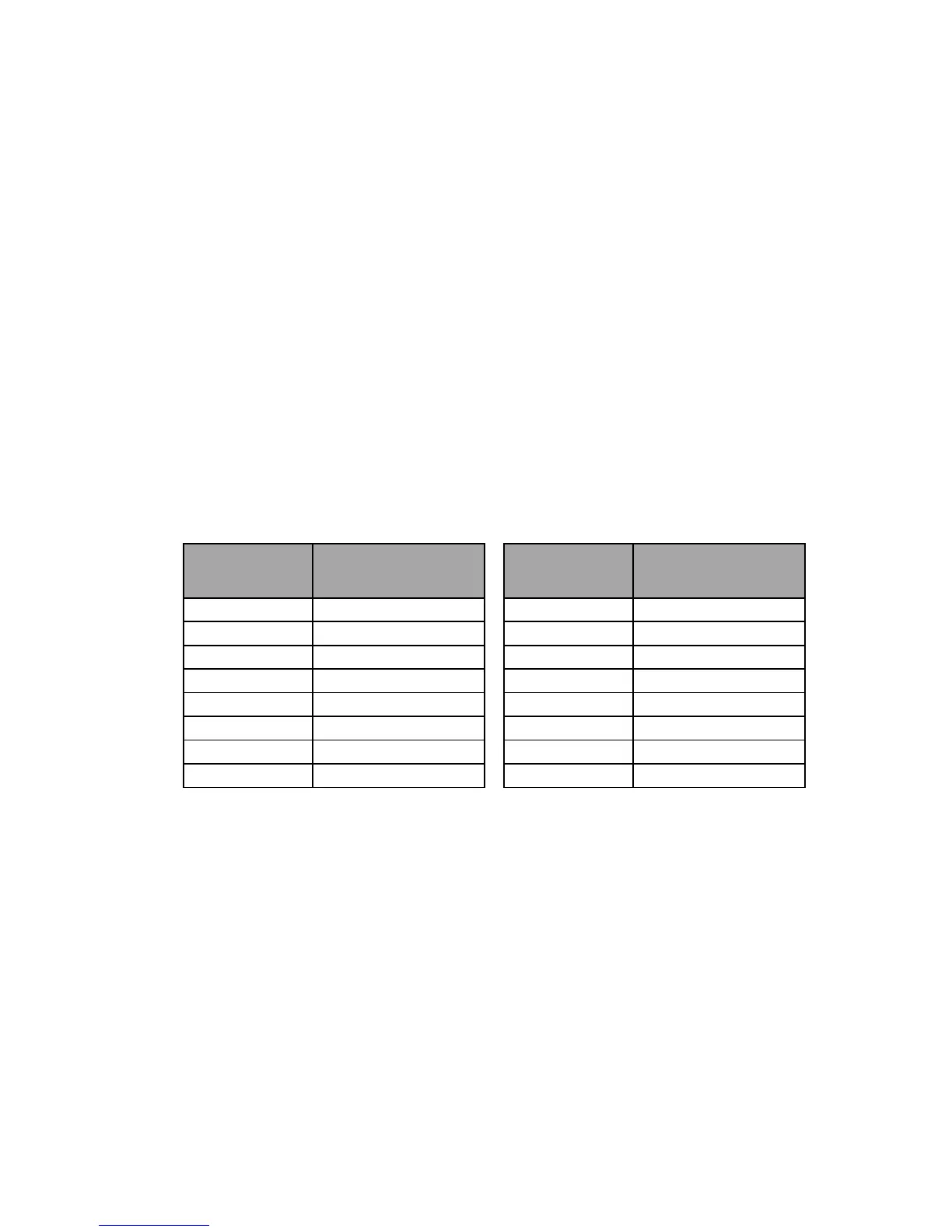

Table 8-1. Operating Ranges for Preset-Range Selection with Rogowski Coil

8.2.2 PRIMARY PRESET-RANGE COMPENSATION OR MONITORING

MODE WITH CURRENT TRANSFORMER

In these modes, a learning-type setup process is not required.

rr

rr

r

.A..A.

.A..A.

.A. should be set to the desired

secondary CURRENT range, and

t.rt.r

t.rt.r

t.r

..

..

. should be set to the TURNS RATIO of the transformer.

The maximum values of

rr

rr

r

.A..A.

.A..A.

.A. are limited by the maximum value of current transformer and the

turns ratio of transformer, the relation is shown by the following equation:

Maximum

rr

rr

r

.A..A.

.A..A.

.A. = Maximum Current of current sensor x Turns Ratio of transformer

COMPENSATION

With

C.rC.r

C.rC.r

C.r

..

..

.=

1212

1212

12,

1414

1414

14,

1616

1616

16 or

1818

1818

18 if using PT2, PT5, PT10 or PT20 as Current Sensor, the control will

operate in PRIMARY PRESET-RANGE COMPENSATION mode. When the control operates

in this COMPENSATION mode, the value of CURRENT setting in the weld schedules should

be input as the desired secondary current in [kA] value.

Current Range

in kA

RANGE Parameter

Current Range

in kA

RANGE Parameter

0 to 2 02.00 0 to 30 30.00

0 to 3 03.00 0 to 40 40.00

0 to 4 04.00 0 to 50 50.00

0 to 5 05.00 0 to 60 60.00

0 to 6 06.00 0 to 70 70.00

0 to 8 08.00 0 to 80 80.00

0 to 10 10.00 0 to 90 90.00

0 to 20 20.00 0 to 100 99.99

Loading...

Loading...