Page 62 • 700120S • ENTRON Controls, LLC.

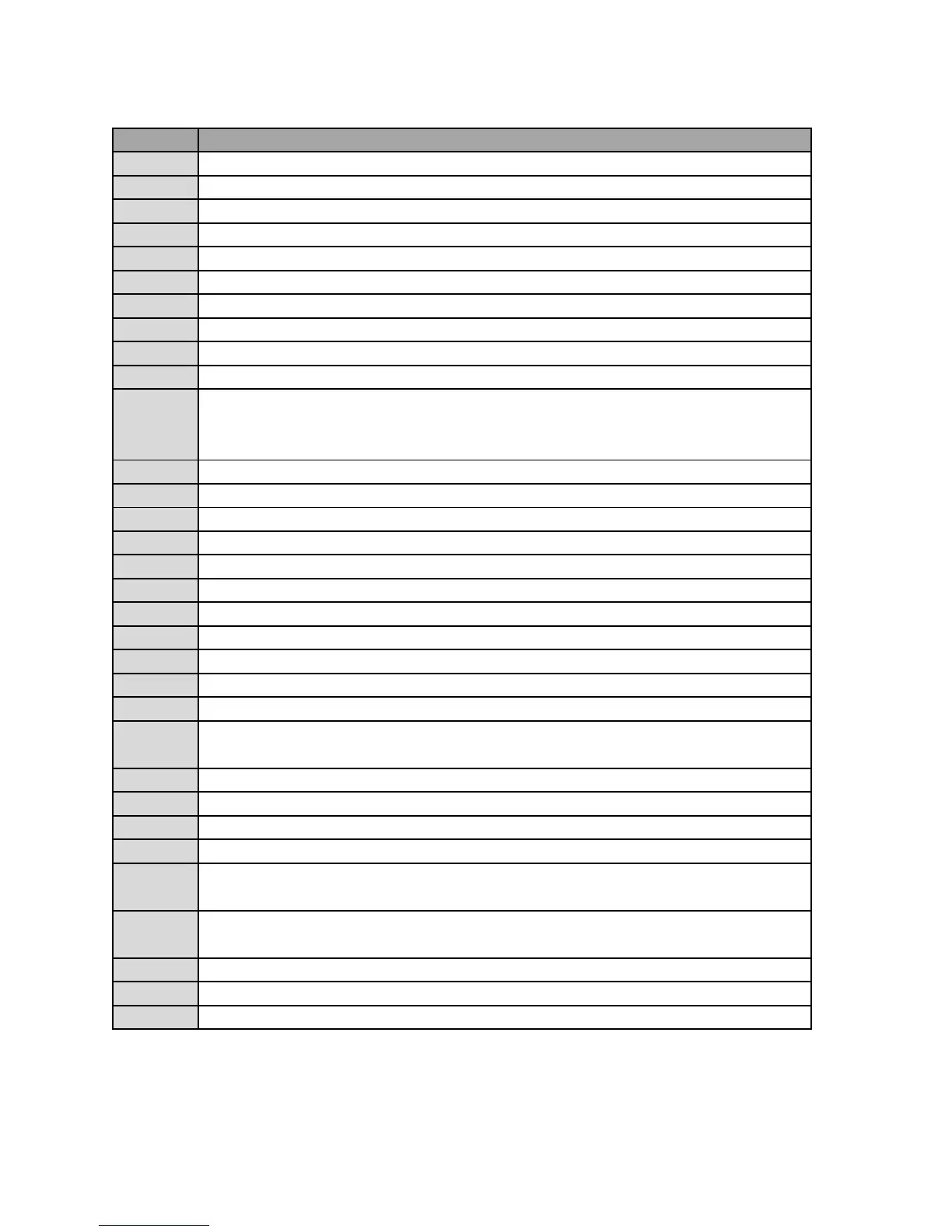

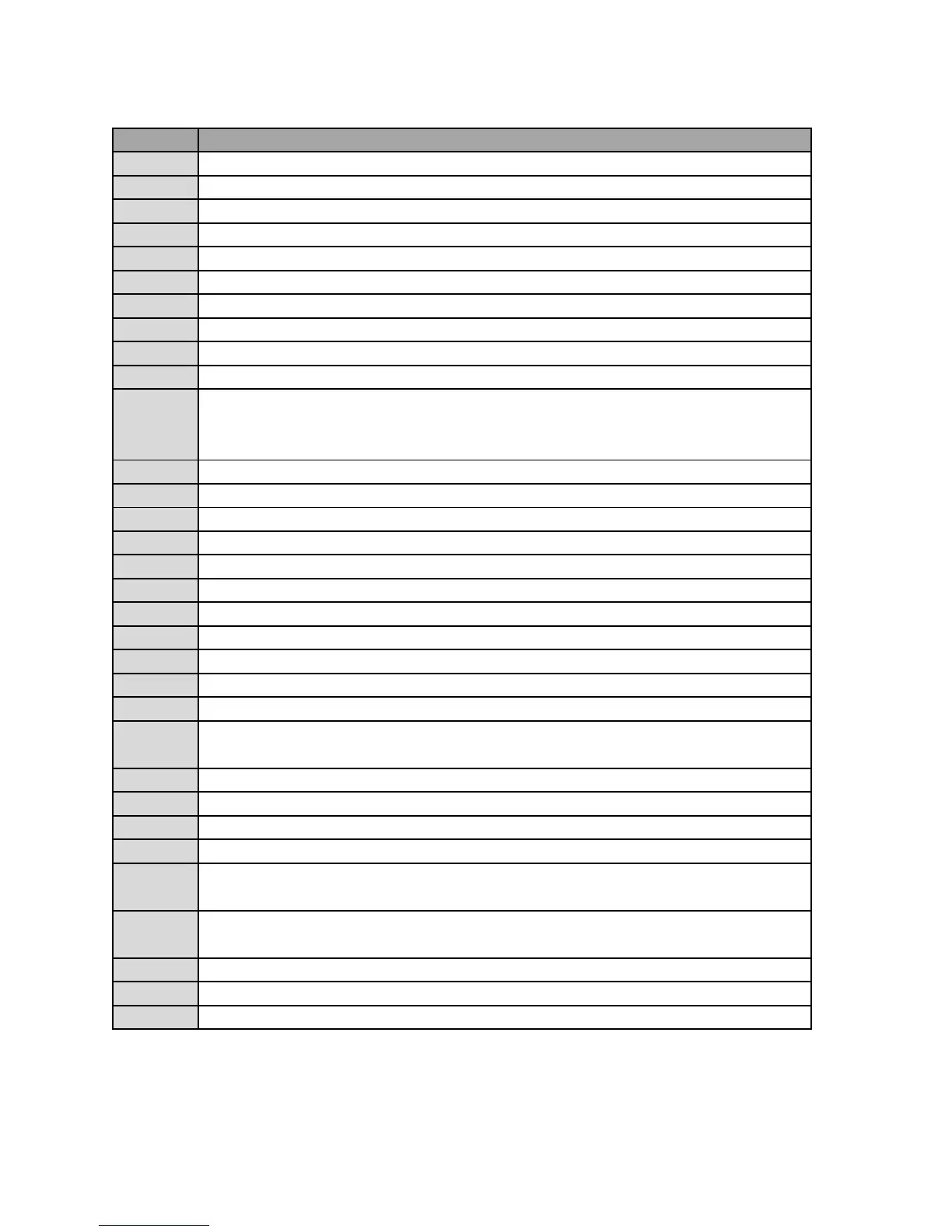

Table 5-6. PROCESS OUTPUT codes and descriptions

5.4.7 PROCESS OUTPUTS –

PP

PP

P

.O..O.

.O..O.

.O. (cont.)

* ONLY available with EN1001 Controls.

CODE PROCESS OUTPUT DESCRIPTION

00 PROCESS OUTPUT disabled

01 ON during WELD

02 ON during WELD and HOLD

03 ON during HOLD

04 ON during OFF

05 ON after OFF until initiation is removed

06 ON for 0.5 seconds after EOS (END OF SEQUENCE)

07 Special AIR OVER OIL RETRACTION

08 RETRACTION mode

09 HALF CYCLE WELD mode

10

ON during any ERROR or control in NO WELD or control in PROGRAM

mode or control in Emergency Stop or in CONSTANT CURRENT mode if

current out of limit window

11 ON when Temperature Limit Switch is OPEN (

=

)

12* Flash

/

if current out of limit window

13* Flash

/

and Valve 3 ON for 0.5 seconds if current out of limit window

14* Flash

/

and break sequence if current out of limit window

15 ON for HARDWARE ERROR or CONTROL RELAY ERROR

16 ON for shorted SCR or L2 missing ERROR (

=

)

17

ON for: TLS ERROR, Memory ERROR, AVC ERRORS, END OF STEPPER, etc.

18 ON when SCR full conduction is detected (

=

)

19 ON during WELD only in WELD mode and closed NW1-GND input on TS1

20 ON after SQUEEZE and during WELD (for welder interlock)

21

reserved

22*

Send HI/LO and current after out of limit window weld or last weld in

sequence with RS232 or RS485 Option

23*

Send HI/LO and current if current out of limit window with RS232 or RS485 Option

24* Flash and indicate

/

if current out of limit window and show CURRENT

25* Indicate

/

and EOS; show CURRENT on DATA display

26*

Flash

/

, stop sequence in HOLD, holding part if current out of limit window

27*

Flash

/

, break sequence and turn Valve 3 ON for 0.5 seconds if current

out of limit window

28*

Indicate EOS: turn Valve 3 ON for 0.5 seconds if current is within limit

window and control in WELD mode and closed NW1-GND input on TS1

29

reserved

30 ON if ERROR

(IPSC or IPS error) occurs

31 ON if ERROR

(IPSC or IPS error) occurs at the end of weld

Loading...

Loading...