Page 108 • 700120S • ENTRON Controls, LLC.

9.1.5 BUTT WELD WITH CHAINED MODE

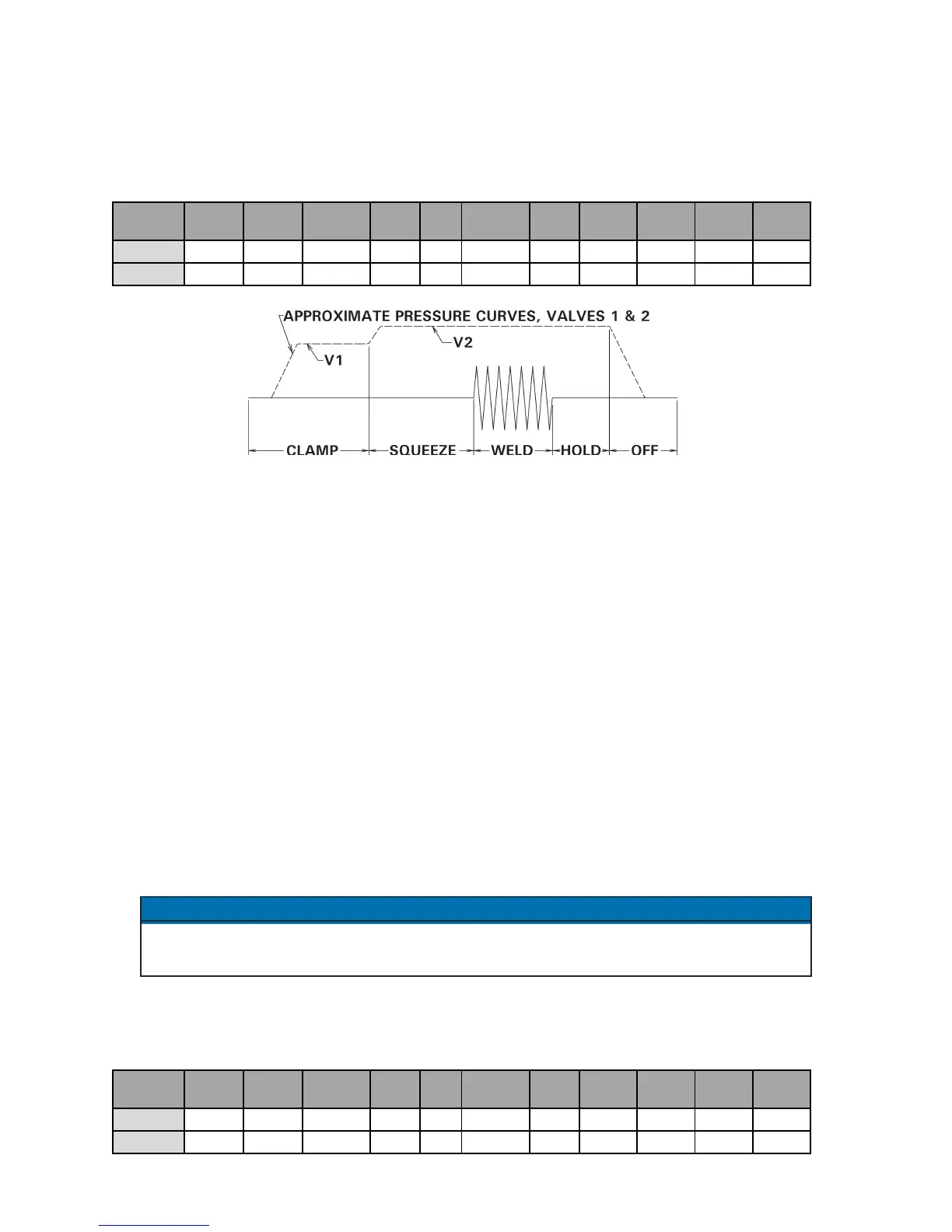

Schedules 11 and 12 are CHAINED together to perform a BUTT welding sequence. Schedule

11 contains only SQUEEZE time with Valve 1 output, and is used as the CLAMP function.

Schedule 12 follows the CLAMP function with a normal SQUEEZE, WELD, HOLD sequence

with Valve 2 output. Both valve outputs turn off at the end of HOLD time.

9.1.6 FORGE DELAY WITH CHAINED MODE

The forging process is most often used when working with hard-to-weld materials such as

aluminum. The weld is usually started at one force, followed by the application of a higher

force during weld or hold time. This action may refine the weld zone, and provide a more

homogeneous weld nugget. Timing of the application of forging force is critical. If applied too

soon, the welding current may be insufficient for the higher force. If applied too late, the weld

will have solidified and the forging force will do no good.

FORGE DELAY is defined as the delay from the beginning of the weld to the activation of the

forging solenoid valve. To accomplish a FORGE DELAY operation on EN1000/EN1001 Series

Controls, it is necessary to CHAIN together two or more schedules as outlined below.

1. Program the first schedule with the amount of WELD time desired before the activation

of the forging valve. Use any one of the three solenoid valve outputs.

2. For FORGE during WELD, program the second schedule with remaining WELD time

and program an unused valve output. This second valve output activates the forging

valve.

For continuous CURRENT from the first schedule to the second schedule, do not program

any HOLD time into the first schedule or SQUEEZE time into the second schedule.

3. For FORGE after WELD, program the number of cycles of time between WELD time

and the activation of the forge valve into HOLD time of the first schedule or into

SQUEEZE time of the second schedule.

Figure 9-5. BUTT weld with CHAINED mode

NOTICE

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

11 20 00 00 00 00 01 00 01 02 00 00

12 20 10 50 10 10 01 00 03 00 00 00

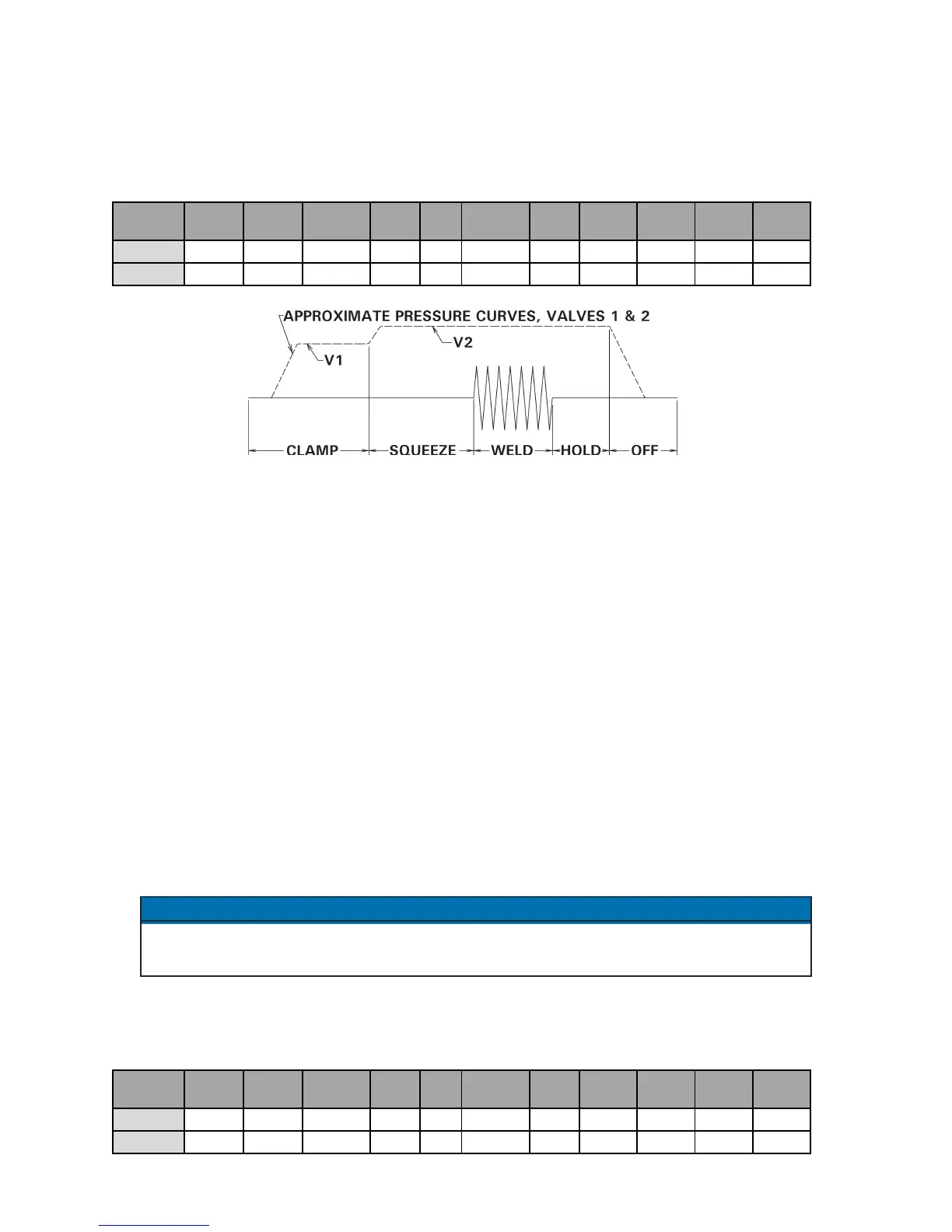

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

00 xx xx xx 00 00 01 00 02 02 00 00

01 00 xx xx xx 00 01 00 06 00 00 00

Loading...

Loading...