Page 86 • 700120S • ENTRON Controls, LLC.

Schedule 20 is used to show how DOWNSLOPE and WELD parts of the sequence are

programmed in a single schedule. The bottom current by default is equal to one quarter of

PERCENT CURRENT. In this example, starting current is 80%; bottom current is: 80%/4 =

20%; and PERCENT CURRENT increment is: (80% - 20%)/10 = 6%.

Schedules 21 and 22 are used to show how two CHAINED schedules can be used to program

WELD and DOWNSLOPE parts of the weld sequence with any desired values for bottom

current of last DOWNSLOPE pulse. The bottom current is 10%, and PERCENT CURRENT

increment is: (75% - 15%)/15 = 4%.

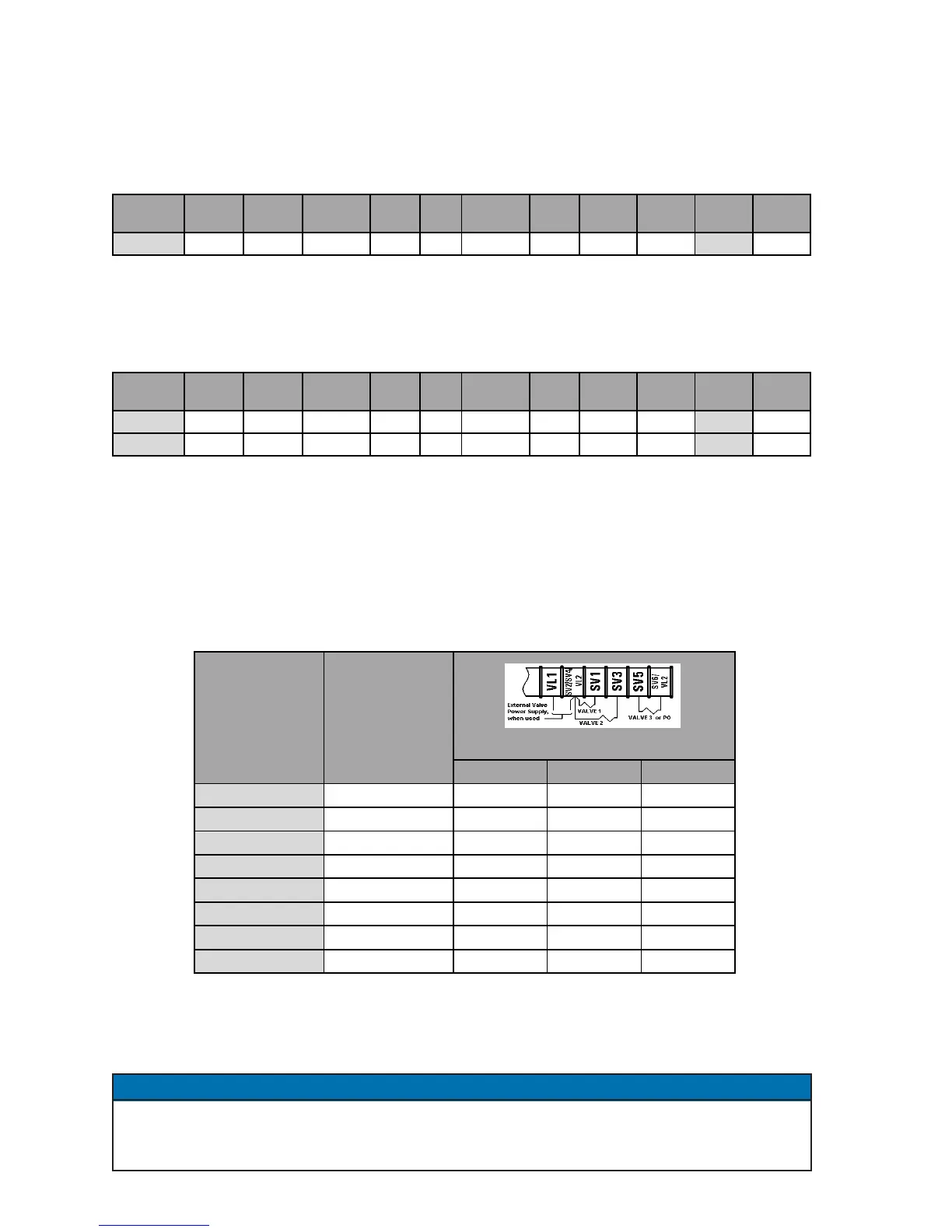

6.4 VALVE MODES

Each programmed schedule can have any one of the three valve outputs (or none) enabled

during its schedule. The three solenoid valves are activated based on the VALVE MODE

programmed as shown in Table 6-2.

Table 6-2. VALVE MODES and Valve Outputs

When in PROGRAM mode and selection of VALVE MODE is being made, the VALVE indicator

LEDs will indicate the selected valve(s). The valve output(s) will not be energized while in

PROGRAM mode.

The VALVE MODES indicated within the valve selection chart may differ with the use of

PROCESS OUTPUTS. Refer to Section 5.4.7 of this manual for further information on the

use of Valve 3 as a PROCESS OUTPUT indicator.

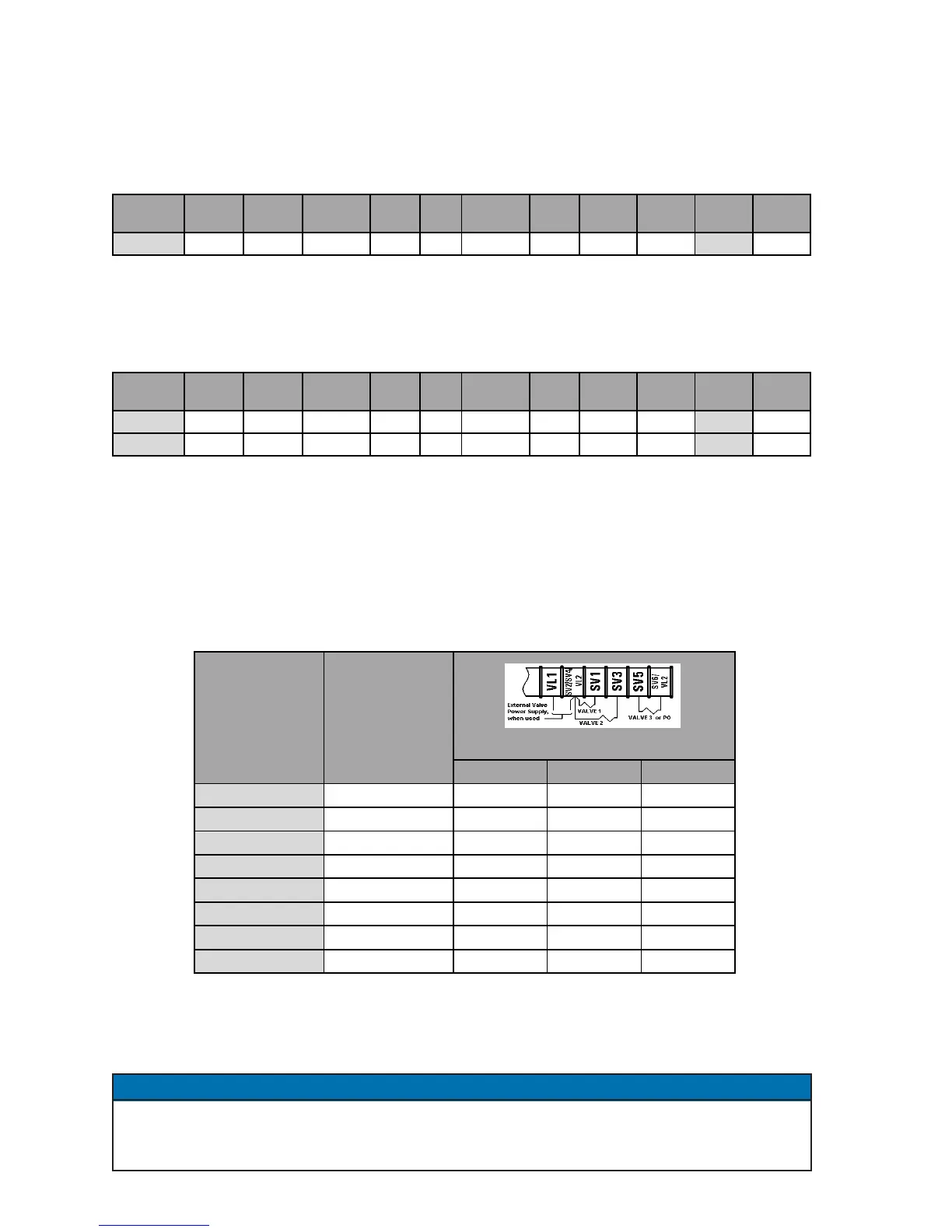

6.3.3 DOWNSLOPE – SLOPE MODE=

0202

0202

02 (cont.)

NOTICE

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

20 10 25 80 20 00 01 00 01 00 02 10

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

21 10 20 75 00 00 01 00 01 02 02 15

22 00 00 15 20 00 01 00 01 00 00 00

TS1-SV5 TS1-SV3 TS1-SV1

00 0 0 0

01 0 0 1 X

02 0 1 0 X

03 0 1 1 X X

04 1 0 0 X

05 1 0 1 X X

06 1 1 0 X X

07 1 1 1 X X X

VALVE MODE

(binary)

VALVE LEDs:

3, 2, 1

Valve Outputs

Loading...

Loading...