ENTRON Controls, LLC. • 700120S • Page 109

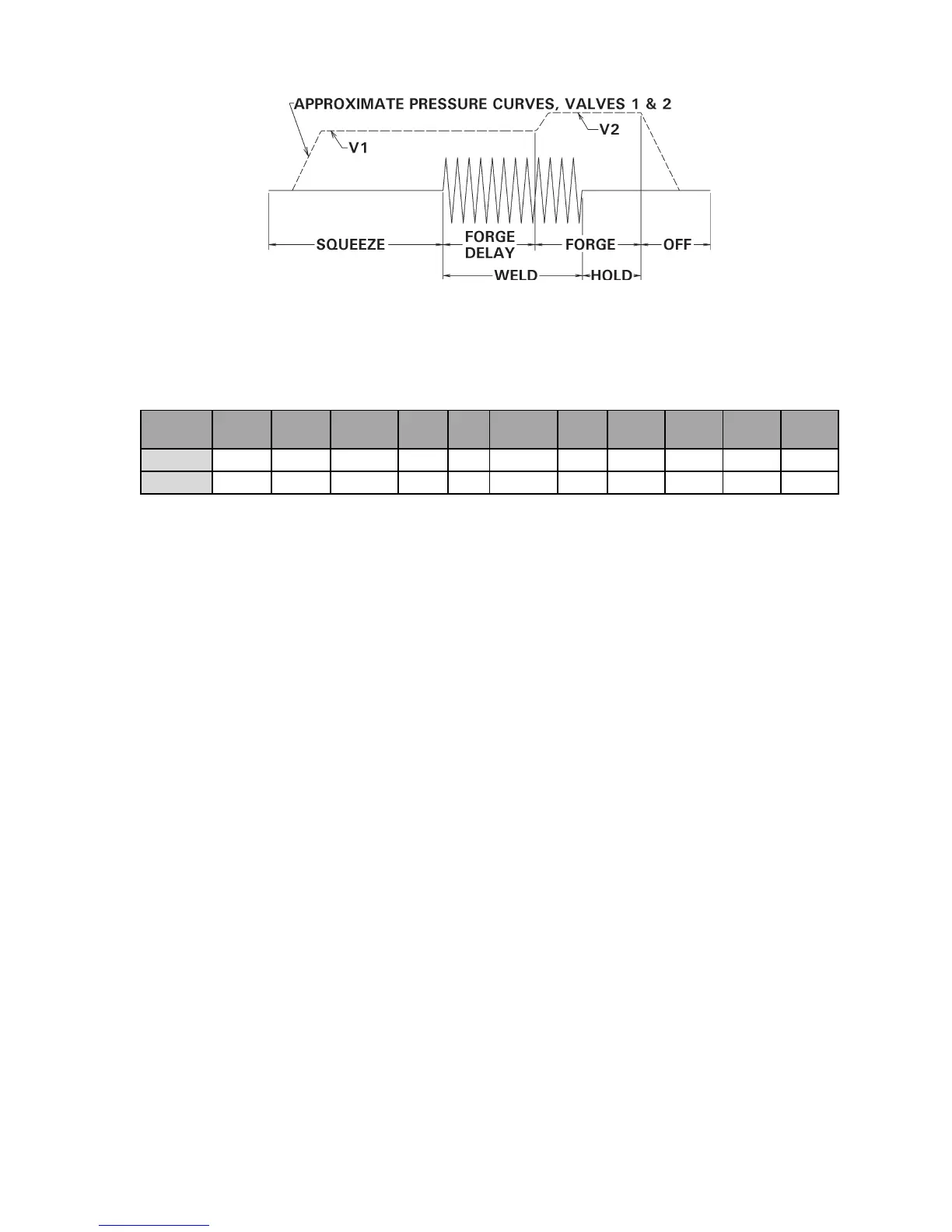

In the next example, Valve 1 will be the standard valve and Valve 2 will be the forging valve.

The total WELD time is 15 cycles at 95 PERCENT CURRENT with the forging valve activated

after 10 cycles.

For FORGE during WELD, it is possible to select a PERCENT CURRENT for the second

schedule different from that of the first schedule.

Other combinations of weld schedules may be combined to create other forging schedules. For

example, it would be possible to use UPSLOPE in the first sequence and PULSATION in the

second sequence.

9.1.6 FORGE DELAY WITH CHAINED MODE (cont.)

Figure 9-6. FORGE DELAY with CHAINED mode

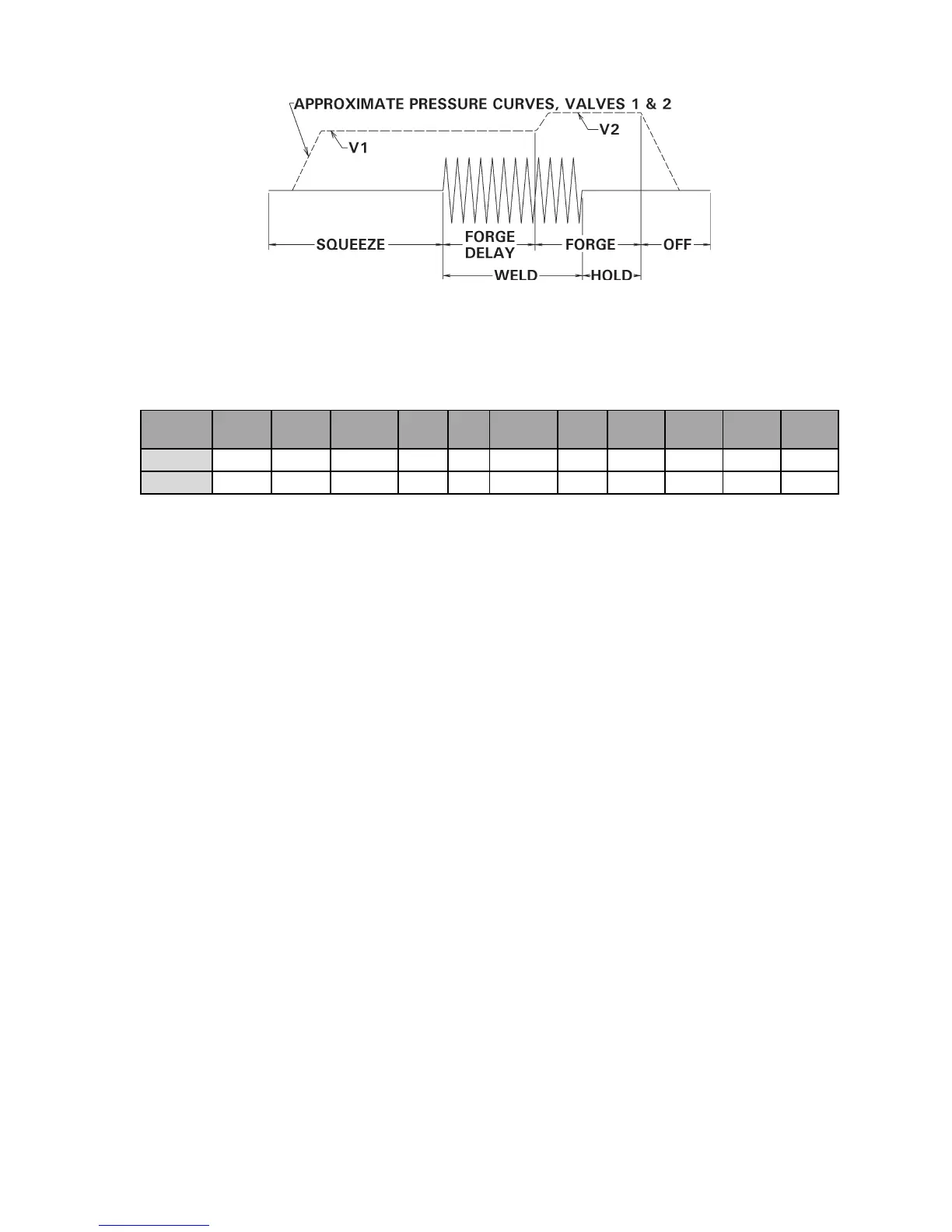

SCHEDULE SQUEEZE

WELD/

HEAT

PERCENT

CURRENT

HOLD OFF IMPULSES COOL

VALVE

MODE

CYCLE

MODE

SLOPE

MODE

SLOPE

COUNT

00 20 10 95 00 00 01 00 01 02 00 00

01 00 05 95 20 00 01 00 03 00 00 00

Loading...

Loading...