ENTRON Controls, LLC. • 700120S • Page 37

PRESSURE SWITCH – This feature is used to make the control wait if the required pressure

has not been reached while in the SQUEEZE interval as follows:

After initiation, the control advances through

SQUEEZE. If the Pressure Switch is open

(pressure not sufficient), the control waits,

and the SQUEEZE LED flashes at the end

of SQUEEZE. When the Pressure Switch

closes (pressure is sufficient), the flashing

stops and the control begins to WELD and

completes the sequence.

If the Pressure Switch interrupts the sequence for an extended period, the display will flash

ERROR CODE

1515

1515

15. This error will not terminate the sequence. Once the Pressure Switch closes,

the sequence will continue on to WELD and complete the sequence. See Section 4.3.2.

If a Pressure Switch is not used, place a jumper (factory installed) between TS1-PS1 and

TS1-GND. Pressure Switch is not furnished with the control.

EN1000/EN1001 Series Controls with PROM firmware version 619016-002J or later will have

the following Pressure Switch function revised. As of this version, the Pressure Switch will be

ignored if WELD time is set to

0000

0000

00. This allows sequences that use features such as CLAMP &

WELD to only have the Pressure Switch checked for the WELD sequence. Before this version,

the Pressure Switch was checked after SQUEEZE in all schedules, including CHAINED

schedules.

TEMPERATURE LIMIT SWITCH – This feature is used to inhibit welding if the temperature

of the switching circuitry is above the rated operating temperature (149E F). If the Temperature

Limit Switch is open (over temperature), the control cannot be initiated until the Temperature

Limit Switch cools (resets/closes). If the Temperature Limit Switch becomes open during a

weld, the weld interval will continue until the end of WELD time; HOLD and OFF will execute

normally but a new sequence cannot be initiated until the Temperature Limit Switch cools and

resets (closes). In either of the above cases, the DATA display will show ERROR CODE

0101

0101

01

until the Temperature Limit Switch recovers its normally closed state; then the control will

return to normal operation.

If the Temperature Limit Switch is not used, place a jumper between TS1-TLS1/AUX1 and

TS1-GND.

EMERGENCY STOP SWITCH – When the Emergency Stop Switch is open, the control

stops any and all processes (all valves and firing pulses). While in the Emergency Stop

condition, the control will flash

E.S.E.S.

E.S.E.S.

E.S. on the DATA and SCHEDULE displays until the condition

has been cleared. If the execution of a schedule was interrupted by means of the Emergency

Stop Switch, the control will not re-initiate automatically (after the Emergency Stop condition

is removed). Upon release of the switch, it must be re-initiated by closing the Pilot Switch.

If the Emergency Stop Switch is not used, place a jumper (factory installed) between TS1-ES1

and TS1-GND. Emergency Stop Switch is not supplied with the control.

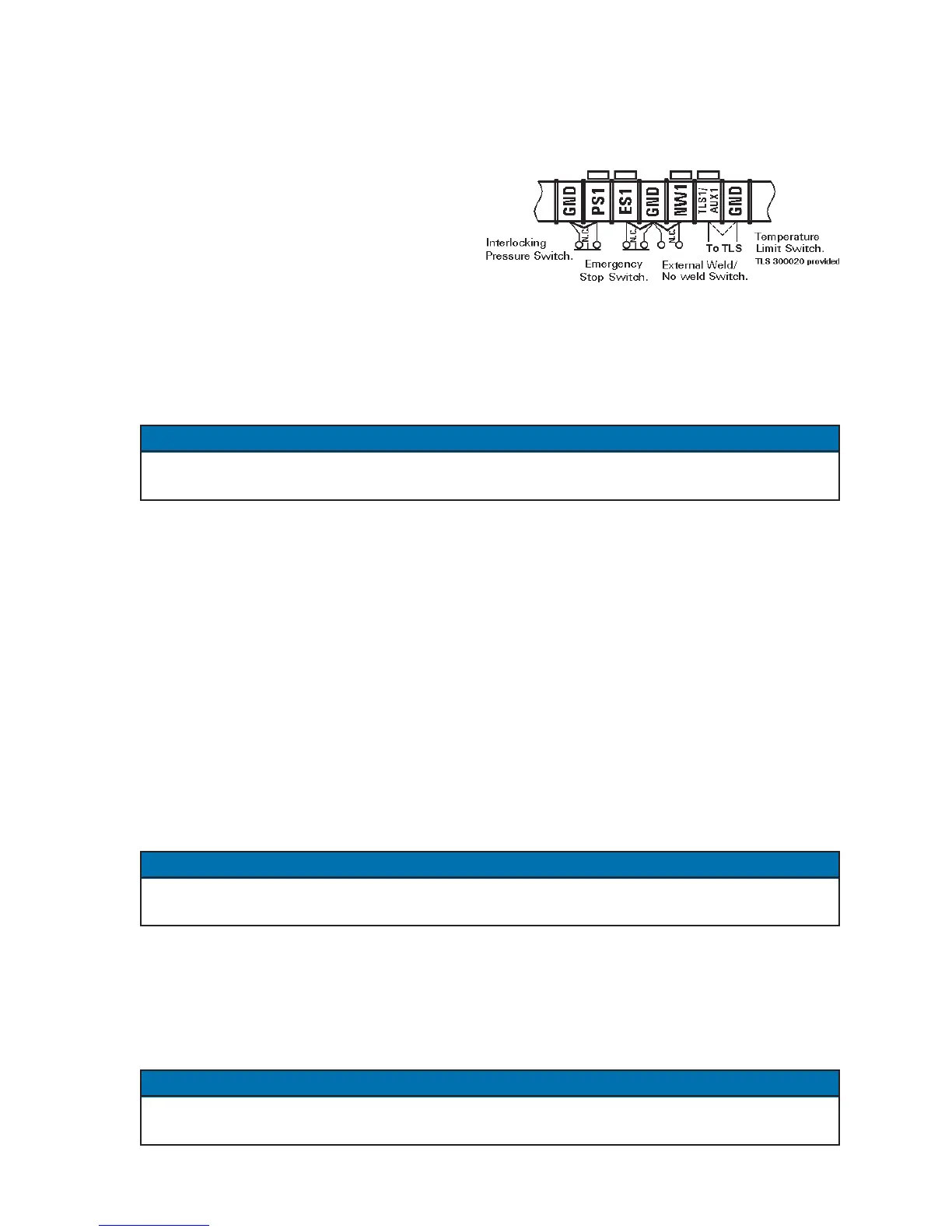

Figure 4-8.

Other inputs on Terminal Strip TS1

4.5 OTHER TERMINAL STRIP INPUTS (cont.)

NOTICE

NOTICE

NOTICE

Loading...

Loading...