ENTRON Controls, LLC. • 700120S • Page 15

2.3 OTHER PROGRAMMABLE SEQUENCE PARAMETERS

IMPULSES (13) – The number of heat IMPULSES that will occur in a schedule.

PERCENT CURRENT (9) – The percentage of conduction time provided to the welding

transformer primary from 0 to 99%, adjustable in 1% steps. This parameter is also used to set

HIGH and LOW limits in CONSTANT CURRENT mode (see Section 8.3.2).

SLOPE MODE (17) – Determines direction of the ramp with respect to programmed weld

PERCENT CURRENT. See Section 6.3 for detailed information on SLOPE MODE functions.

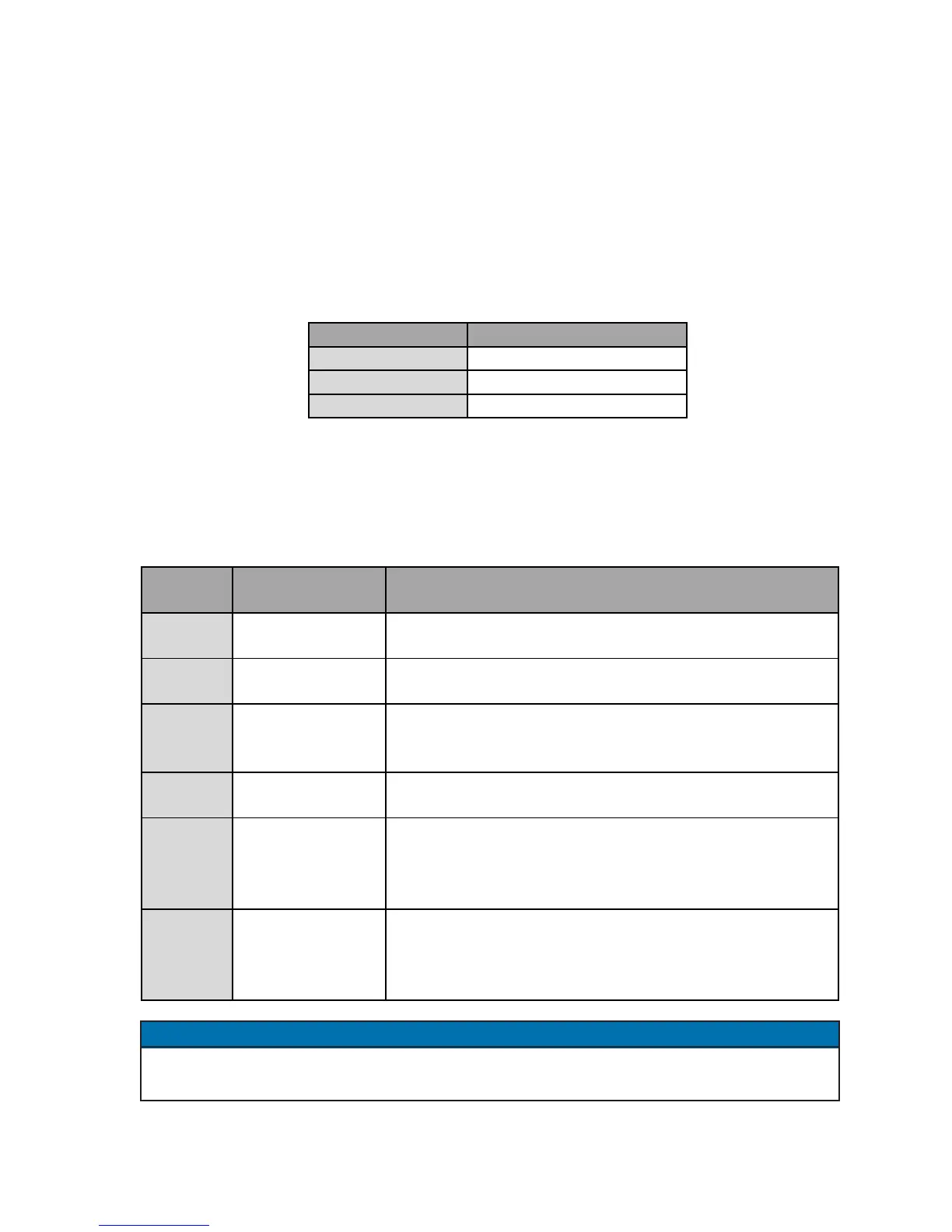

Table 2-1. SLOPE MODES

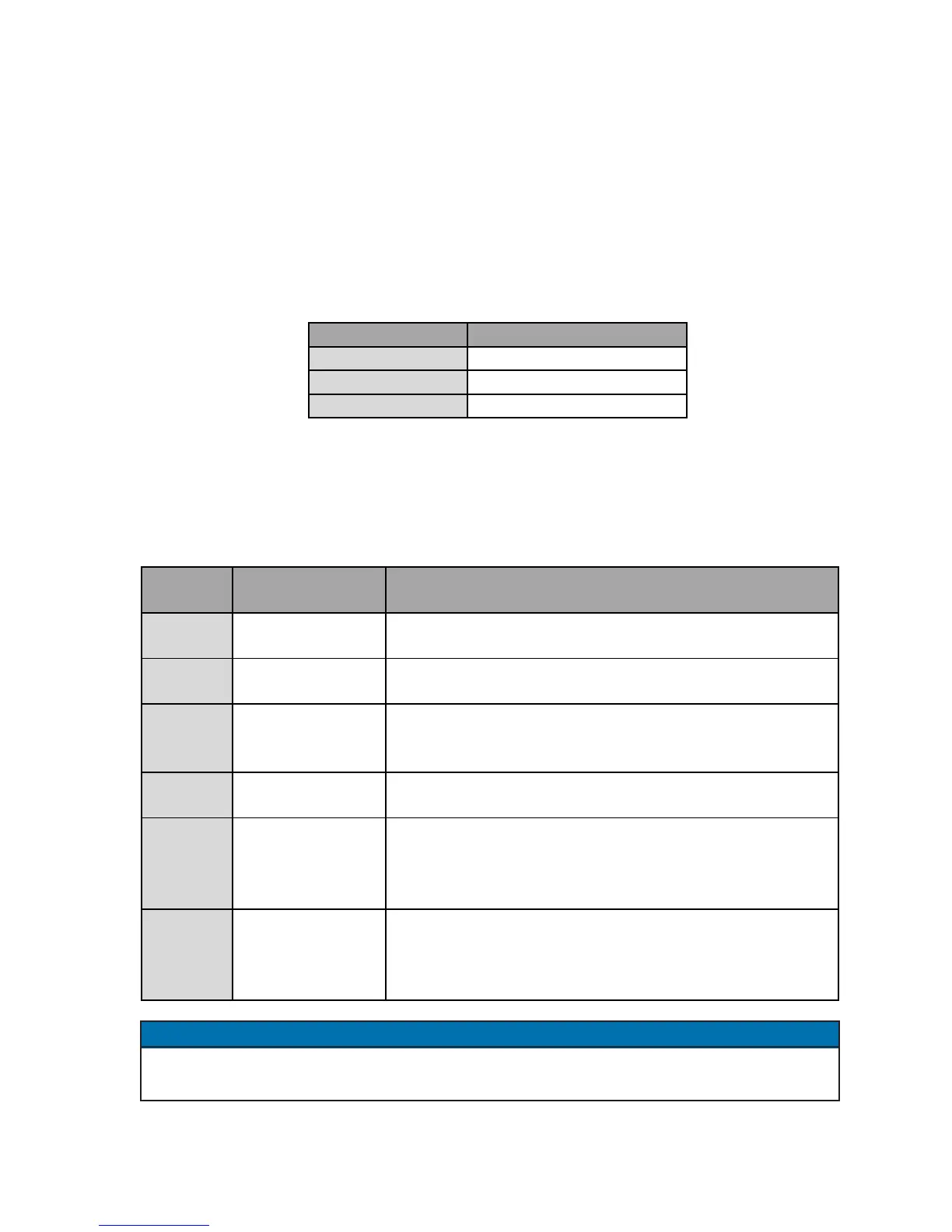

CYCLE MODE (16) – The manner in which the control performs schedules is determined by

the code programmed into this function as described in Table 2-2. See Section 6.2 for detailed

information on CYCLE MODE functions.

Table 2-2. CYCLE MODES

The CYCLE MODE and SLOPE MODE function codes are printed on the Control Panel,

adjacent to the ENTER push button, for operator convenience.

NOTICE

SLOPE MODE Description

00

NO SLOPE

01

UPSLOPE

02

DOWNSLOPE

CYCLE

MODE

MODE

Description

00 NON-REPEAT

The control can be initiated for only one sequence (see

Section 6.2.1)

01 REPEAT

After initiation, the control internally re-initiates as long as

the initiation switch is maintained closed (see Section 6.2.2)

02 CHAINED

Several schedules can be chained together so that several

consecutive schedules can be sequenced from one initiation

(see Section 6.2.3)

03 SUCCESSIVE

Several schedules can be sequenced successively upon

separate initiations (see Section 6.2.4)

04

CONDITIONAL

SUCCESSIVE

Valves remain active at the end of HOLD (this is indicated

by blinking HOLD indicator LED ) until control is re-

initiated and next schedule will be sequenced (see Section

6.2.5)

05 WAIT-HERE

After FS3 initiation, wait either in SQUEEZE or WELD-

COOL or HOLD part of the sequence until control is re-

initiated with FS7 or FS11 and schedule 10 or 20 will be

sequenced (see Section 6.2.6)

Loading...

Loading...